8.10.3 Mechanical faults

The following table shows the possible causes of and remedial measures for mechanical

faults.

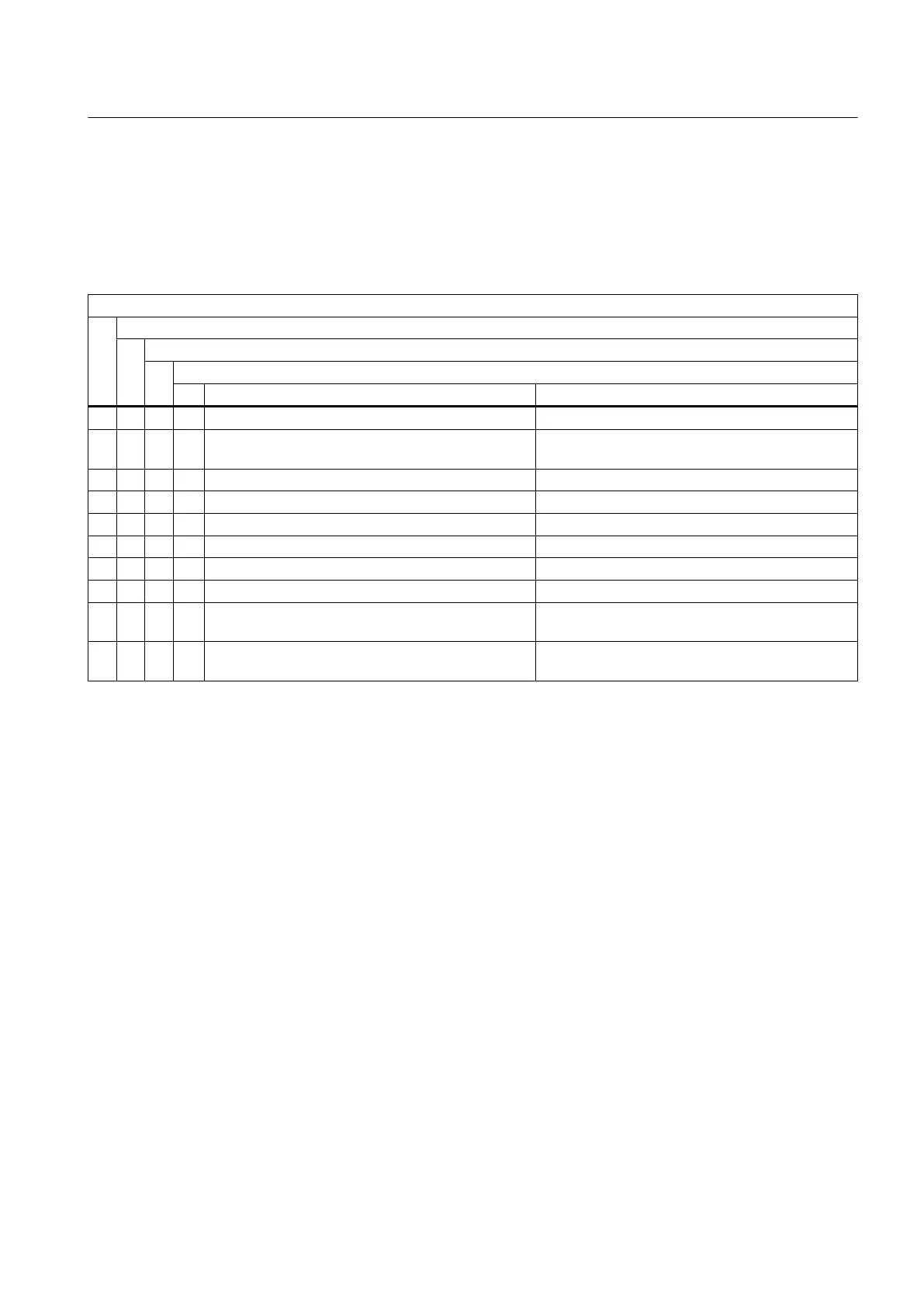

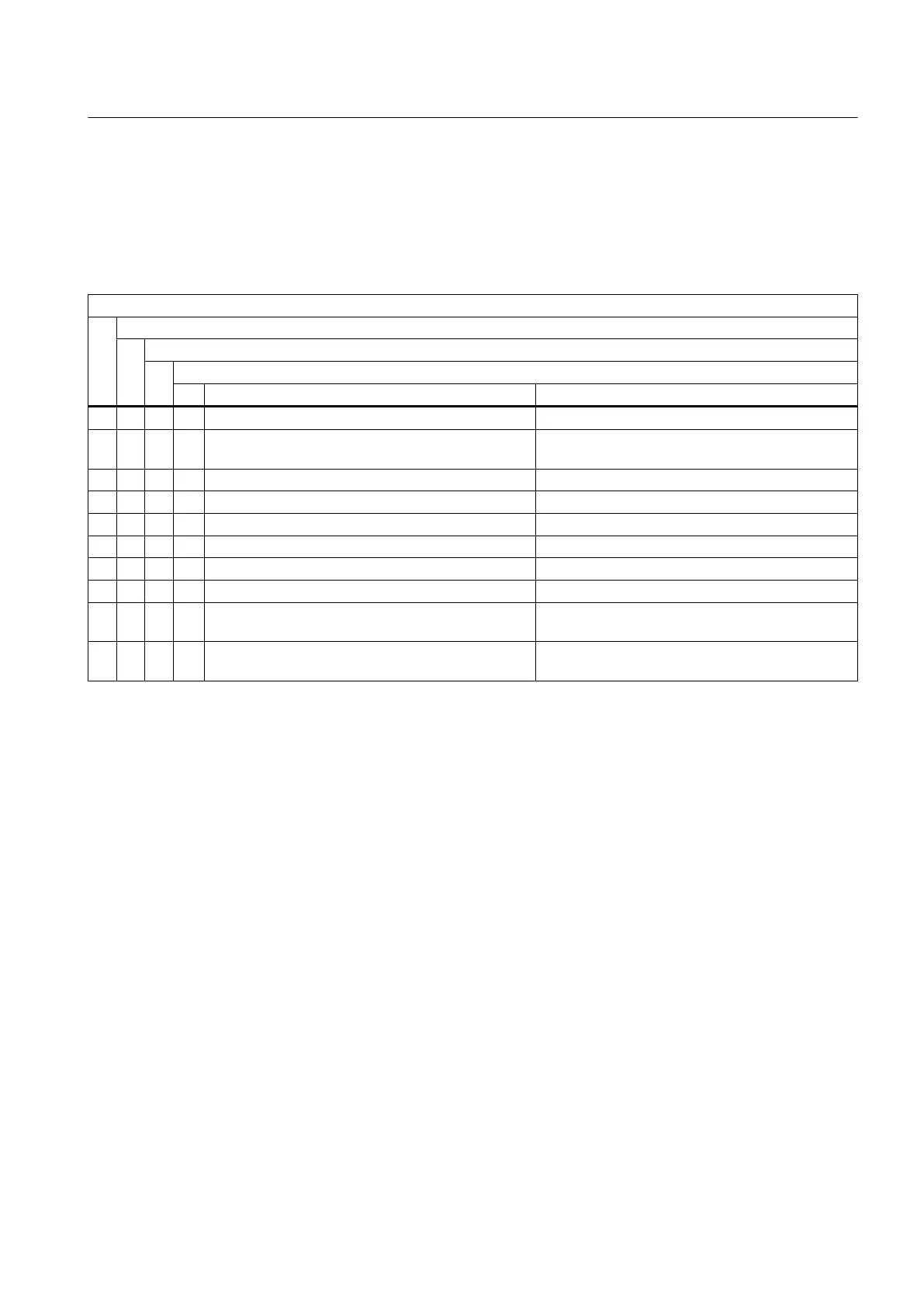

Table 8-2 Mechanical faults

↓ Grinding noise

↓ Overheating

↓ Radial vibrations

↓ Axial vibrations

Possible causes of faults Remedial measures

X Rotating parts are grinding Establish the cause and realign the parts.

X Reduced air supply, direction of rotation of fan pos‐

sibly incorrect

Check the air ducts; clean the machine.

X Rotor not balanced Decouple the rotor and then rebalance it.

X Rotor out of true, shaft bent Please consult the manufacturer.

X X Poor alignment Align the machine set and check the coupling

①

.

X Coupled machine not balanced Rebalance the coupled machine.

X Shocks from coupled machine Investigate the coupled machine.

X X Fault originating from gearing Fix the gearing.

X X Resonance of the overall system comprising motor

and foundation

Reinforce the foundation after consultation with the

manufacturer.

X X Changes in foundation Determine the cause and rectify it. Realign the ma‐

chine.

①

Note any changes taking place during warm up

Operation

8.10 faults

SIMOTICS TN Series N-compact 1LA8

Operating Instructions 08/2017 103

Loading...

Loading...