3. Fasten the cable lug to the end of the conductor correctly, e.g. by squeezing.

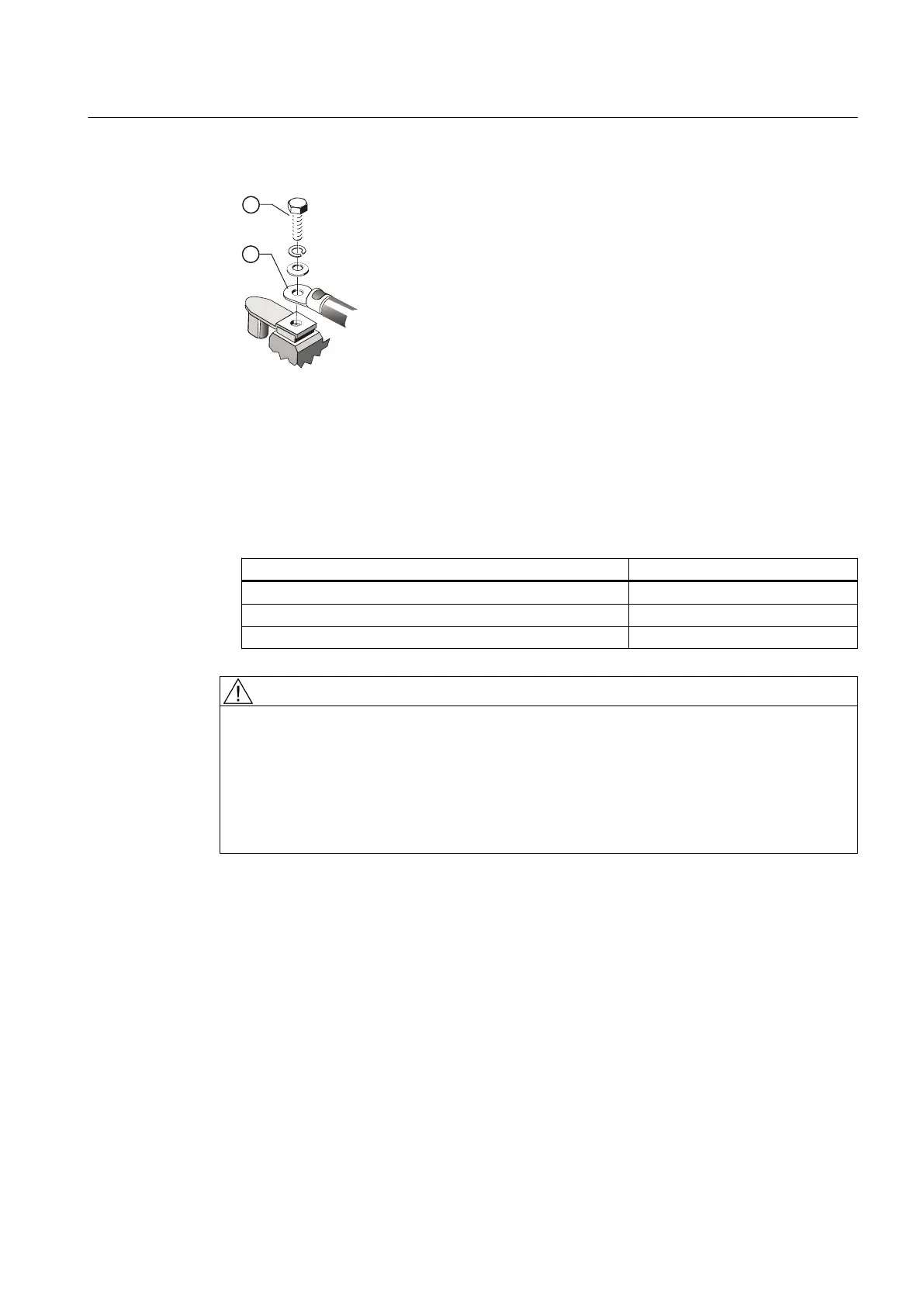

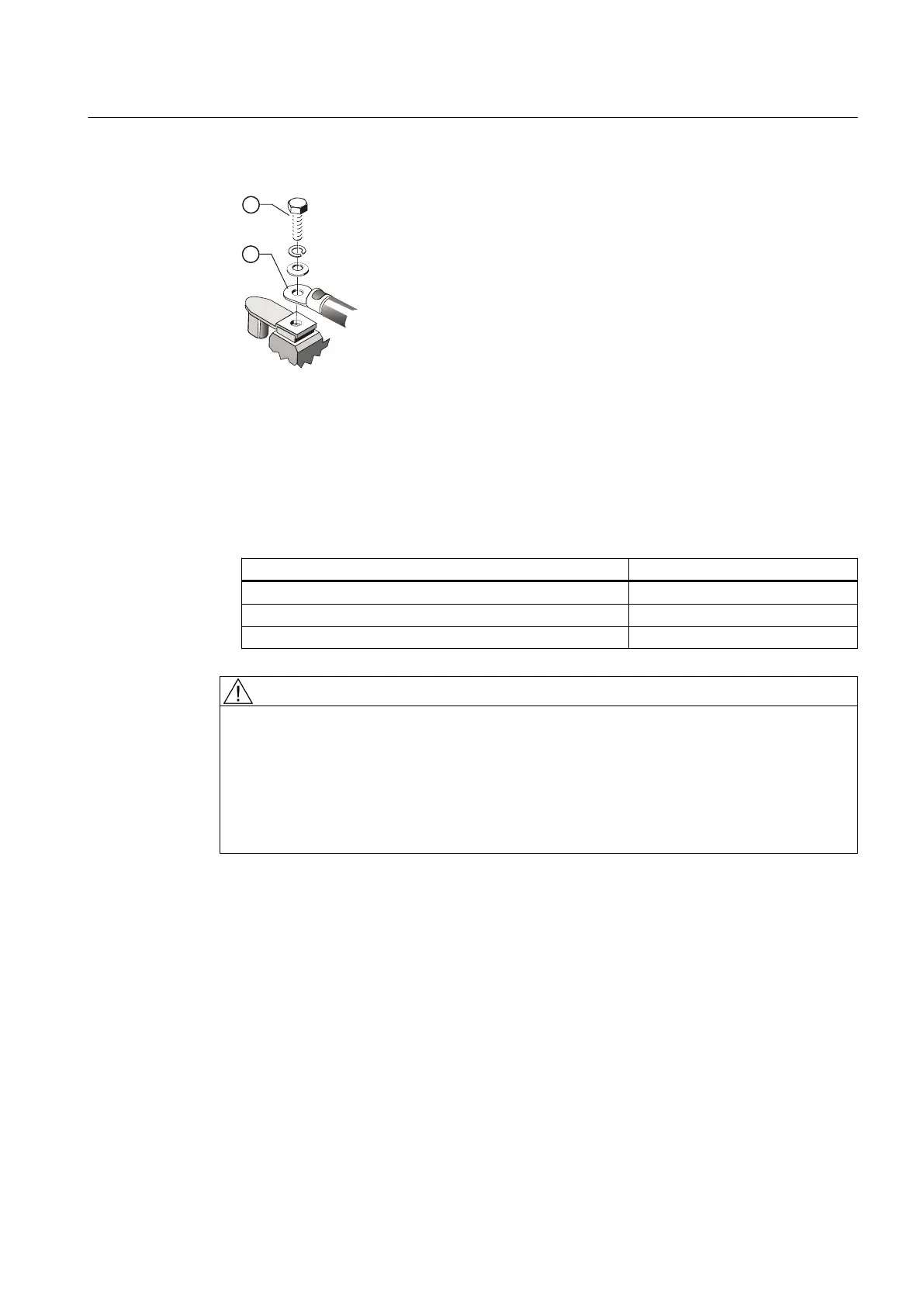

Figure 6-7 Connection with cable lug and fixing screw (schematic diagram)

4. Insulate the cable lug sleeves where necessary to ensure minimum air clearances and the

creepage distance are maintained.

5. Place the cable lug on the terminal support. If you are using a disconnecting link, check its

positioning.

For terminal boxes 1XB7740 and 1XB7750, place the cable lug on the busbar.

6. Tighten the fixing element ② with the corresponding tightening torque:

Fixing element Tightening torque

Fastening screw M12 20 Nm

Fixing screws M16 40 Nm

Fixing nuts M12 20 Nm

WARNING

Explosion hazard if cable lugs without side guards are used

For cable cross-sections under 70 mm

2

, cable lugs without side guard may twist. The

minimum air clearances may be underrun and cause an explosion.

This can result in death, serious injury, or material damage.

● For cable cross-sections under 70 mm

2

, use only cable lugs with side guard.

● Make sure that the minimum air clearances (Page 83) are observed.

6.4.6 Connection without cable lugs

Lug terminal connections - which are suitable for connecting flexible and stranded conductors

without the use of wire end ferrules - may be installed if ordered accordingly. If you wish to

Electrical connection

6.4 Introducing and routing the cables

SIMOTICS TN Series N-compact 1LA8

Operating Instructions 08/2017 79

Loading...

Loading...