Rolling-contact bearings

The machines are equipped with different types of rolling-contact bearings depending on the

version and the operating conditions described in the order. The different types are listed on

the lubricant plate of the machine. In converter operation an insulated bearing is usually

installed on the non-drive end. The following rolling-contact bearing variants are available:

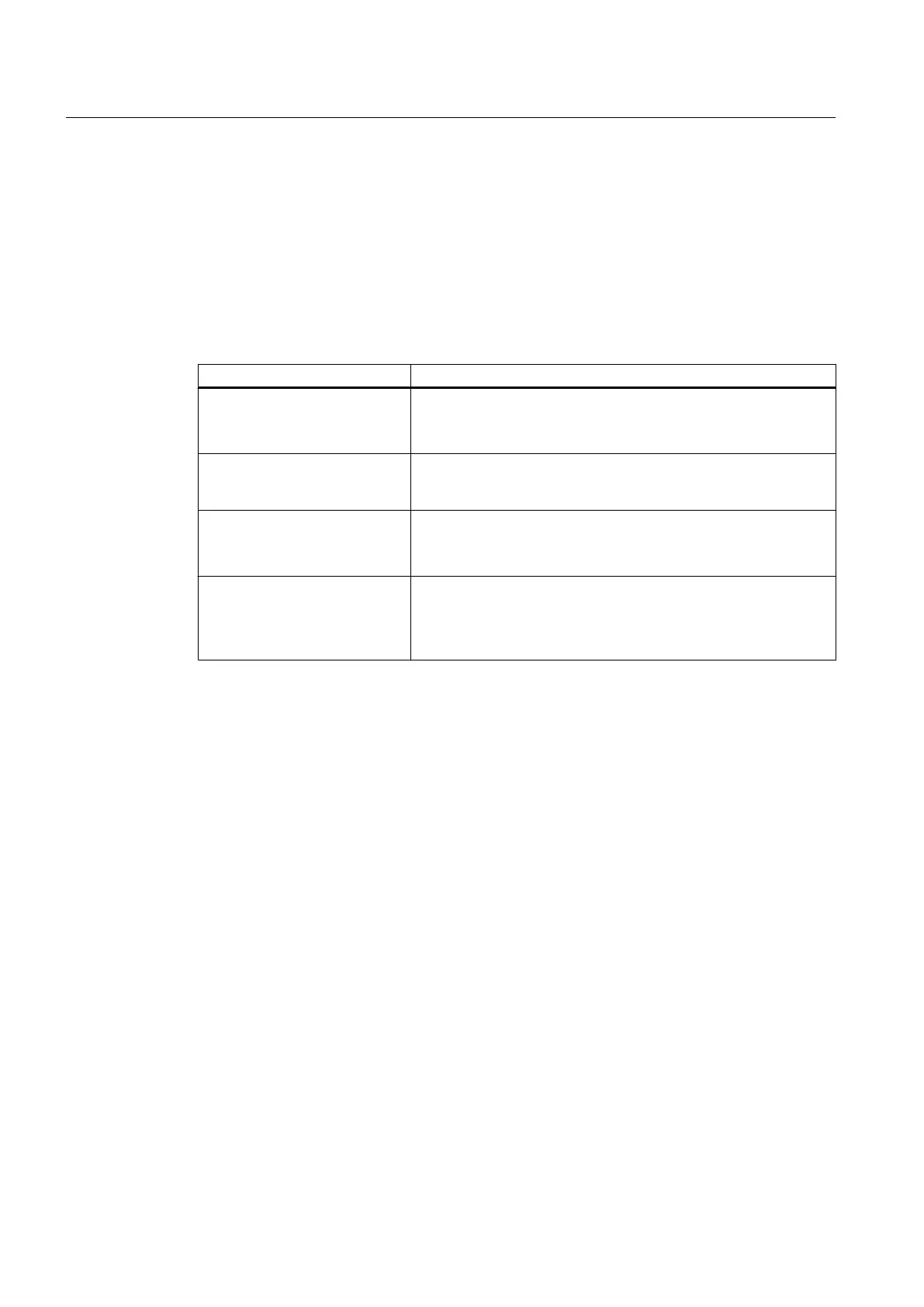

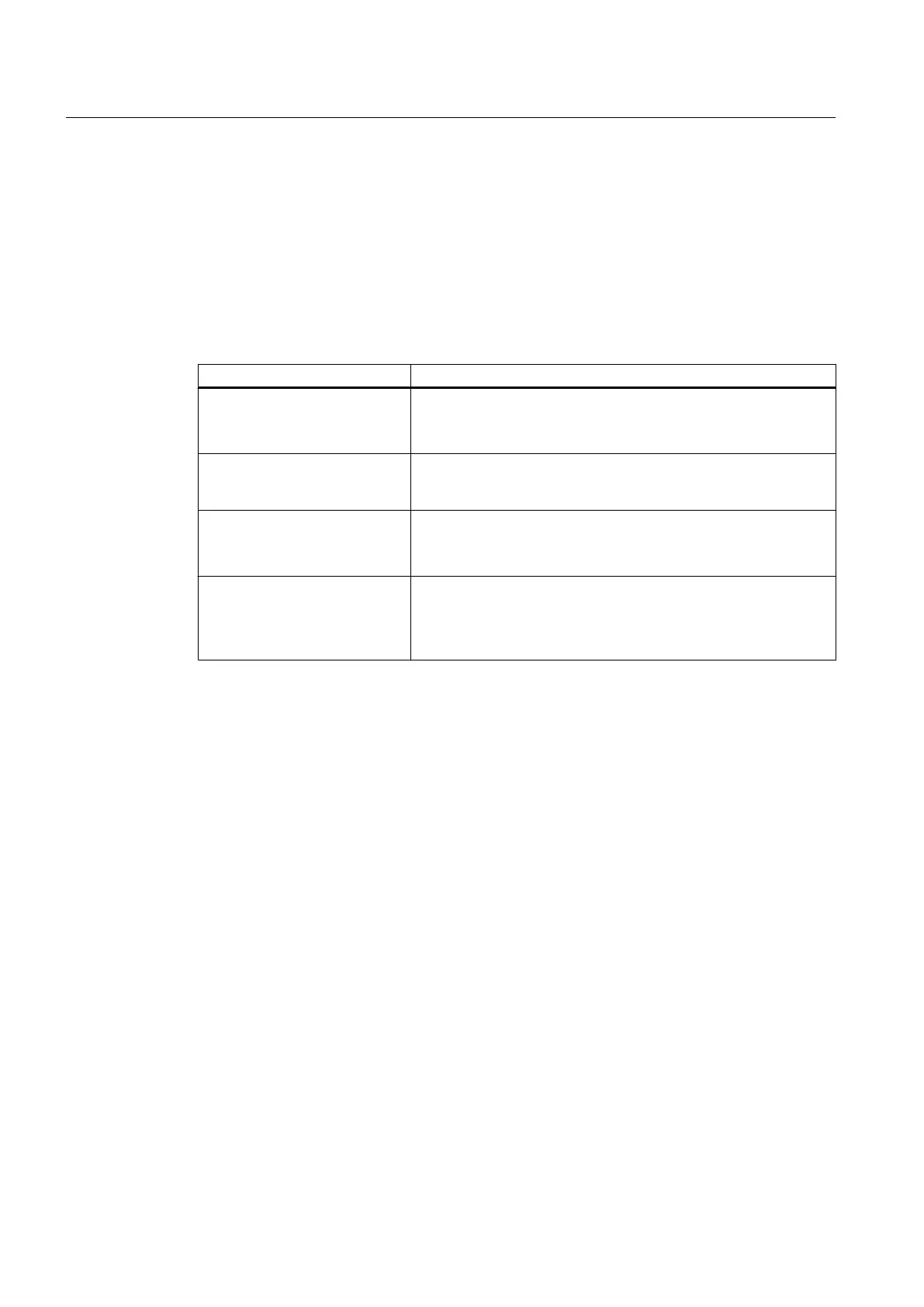

Table 3-4 Rolling-contact bearing variants

Version Rolling-contact bearing

Horizontal type of construction,

coupling output

● Drive end: Deep-groove ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

Horizontal type of construction,

for increased transverse forces

e.g. in the case of belt coupling

● Drive end: Cylindrical-roller bearing as a floating bearing

● Non-drive end: Deep-groove ball bearing as a fixed bearing

Vertical type of construction,

shaft height 315, coupling output

● Drive end: Deep-groove ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

Vertical type of construction,

shaft height 355 ... 450

● Drive end: Pairing of angular-contact ball bearing / deep-groove

ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

Rolling-contact bearing design for "Increased degree of protection" (option)

Improved sealing of the bearing units to prevent dust and water from getting in can be achieved

by positioning a grease chamber ahead of the actual bearing unit. Although the same grease

is used in both cases for reasons of convenience, a distinction is made here between

"lubricating grease" and "sealing grease" because of their different functions.

Layout

The spent lubricating grease collects in the space between the bearing housing and the outer

bearing cap. The latter also forms the sealing grease chamber with the labyrinth sealing ring

(optional). The second lubricating nipple containing the grease duct for pressing in the sealing

grease is also located in the outer bearing cap. The chamber is sealed off from the space

where the lubricating grease collects by a V-ring or a V-ring and felt ring combination which

prevents the sealing grease in the chamber from penetrating into the lubricating grease

collecting space. During operation, the sealing grease in the chamber slowly runs out via the

labyrinth and seals it, additionally removing dust from inside and around the outside of the

labyrinth ring.

Terminal box

The terminal box can be arranged either on the left or right of the machine. It is not possible

to change the position to the other side of the machine at a later date.

Description

SIMOTICS TN Series N-compact 1LA8

28 Operating Instructions 08/2017

Loading...

Loading...