Loading...

Loading...

Do you have a question about the Siemens 3RW44 and is the answer not in the manual?

| Temperature range | -25°C to +60°C |

|---|---|

| Degree of protection | IP20 |

| Product category | Soft starter |

| Product designation | 3RW44 |

| Type of voltage | AC |

| Protection class IP | IP20 |

| Standards | IEC 60947-4-2 |

| Overload class | Class 10, 20 |

Explains the physical principles of three-phase asynchronous motors and their starting characteristics.

Describes how the 3RW44 soft starter uses antiparallel thyristors to control motor voltage.

Covers typical applications and selection criteria for 3RW44 soft starters.

Details on basic configuration, including PC interface and simulation tools.

Explains the importance of startup class for soft starter design and selection criteria.

Covers unpacking, mounting position, installation requirements, and clearances.

Explains general feeder design, disconnectors, and contact elements.

Describes connection of soft starters in standard motor feeder circuits.

Details the requirements and connection for inside-delta circuit configurations.

Explains protection methods, including type of coordination 1 and 2.

Covers control, auxiliary, and main circuit connections.

Guides on navigating menus and modifying parameters.

Provides a recommended procedure for initial device commissioning.

Details steps for custom configuration, including parameter sets, motor data, and I/O.

Covers selection and adjustment of various parameters like startup modes and coasting methods.

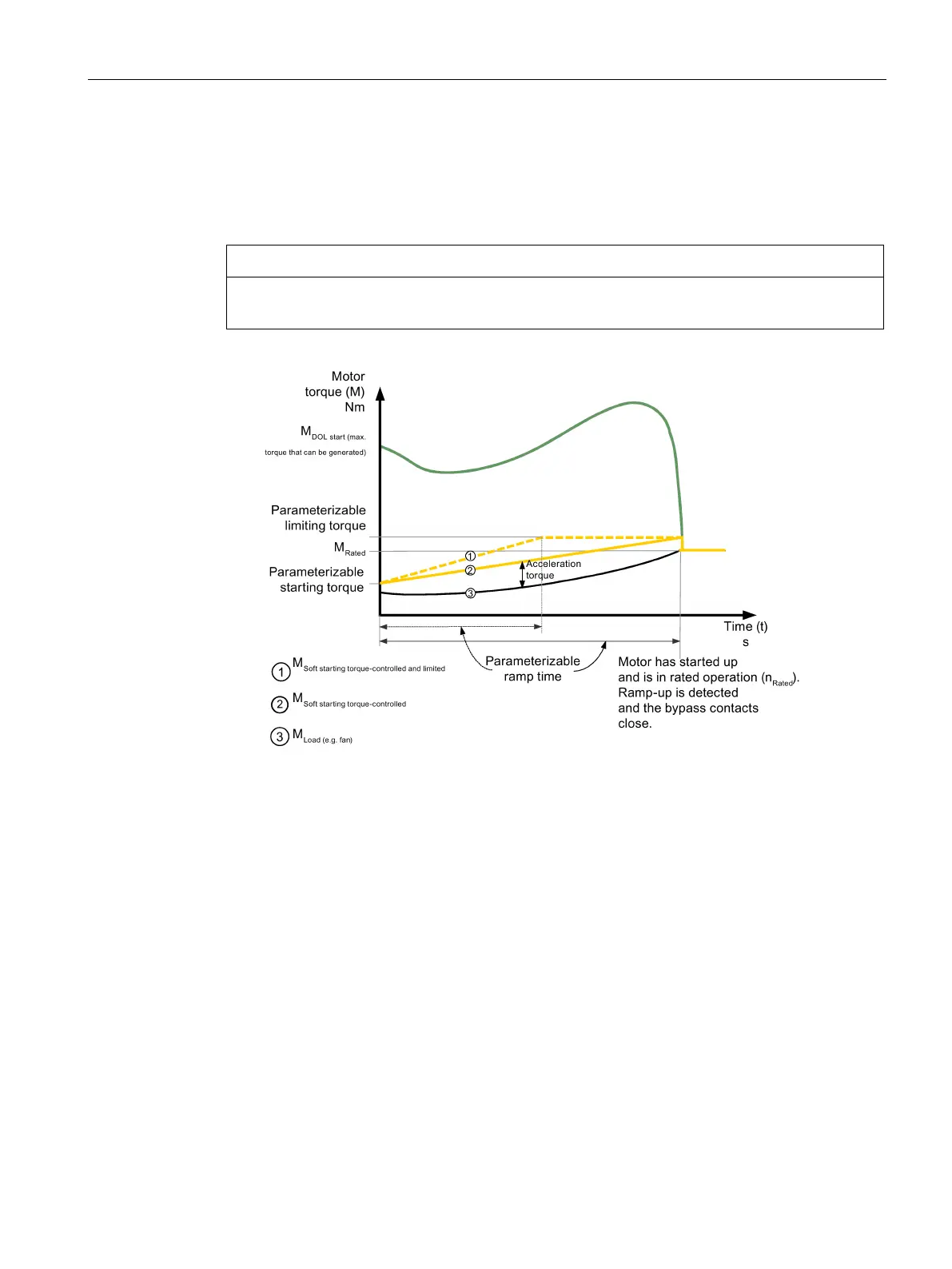

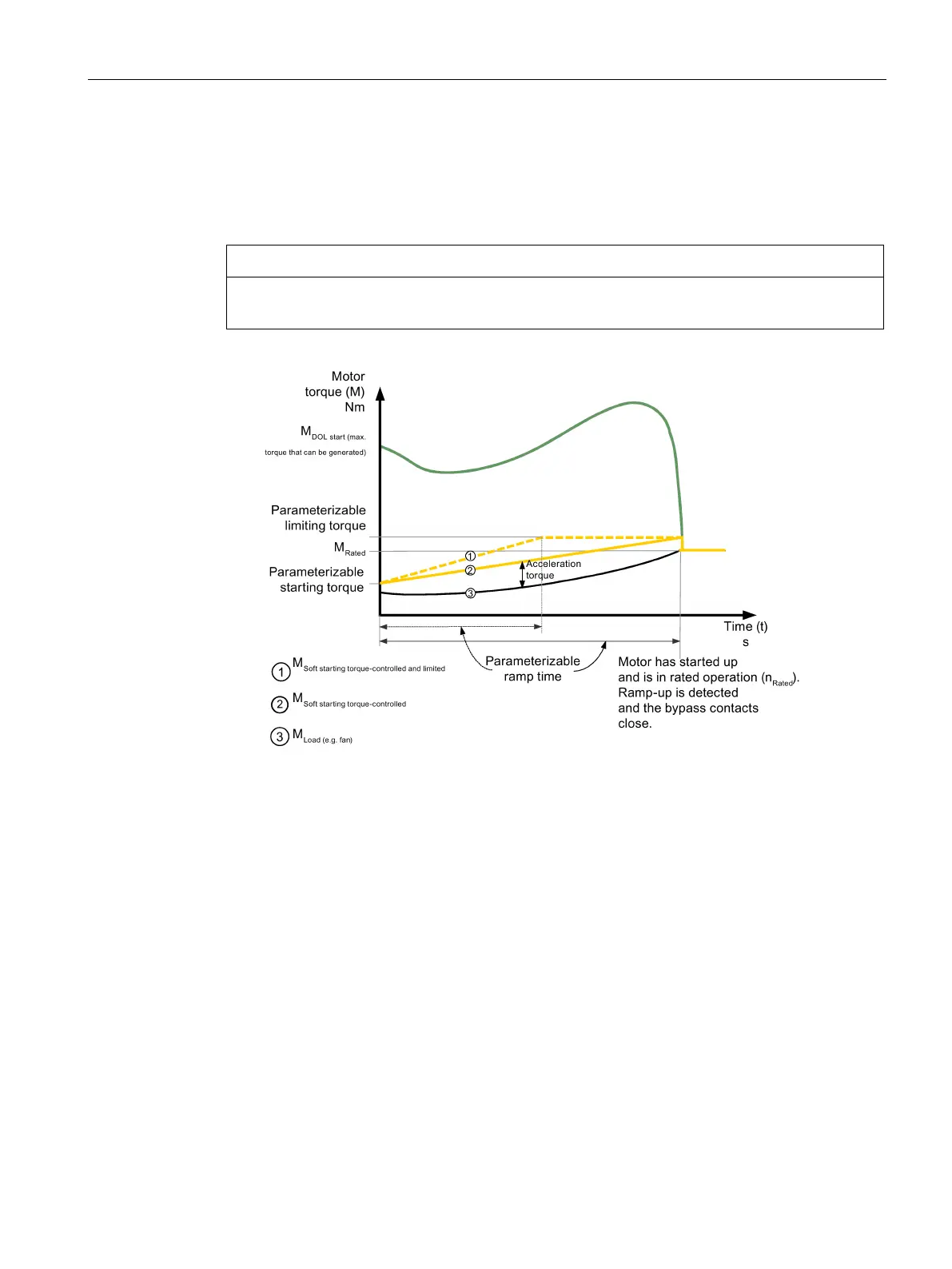

Details various startup modes like Voltage Ramp, Torque Control, and Current Limitation.

Covers different stopping methods such as Coasting Down, Torque Control, and DC Braking.

Describes operation at lower speeds and its limitations.

Details motor overload protection, tripping classes, and asymmetry limit values.

Describes the internal protection mechanisms preventing thyristor thermal overloading.

Provides an overview of status messages, warnings, group faults, and device faults.

Guides on installing the PROFIBUS DP communication module, including safety precautions.

Details activation via display or software and setting the station address.

Covers configuration using GSD files and Soft Starter ES Professional software.

Provides an example of commissioning using GSD files in STEP 7.

Shows component layouts for standard circuits with fuse assignment.