Motor components and options

4.2 Options

1FK2 synchronous motors for SINAMICS S120

44 Configuration Manual, 06/2019, A5E46927724B AB

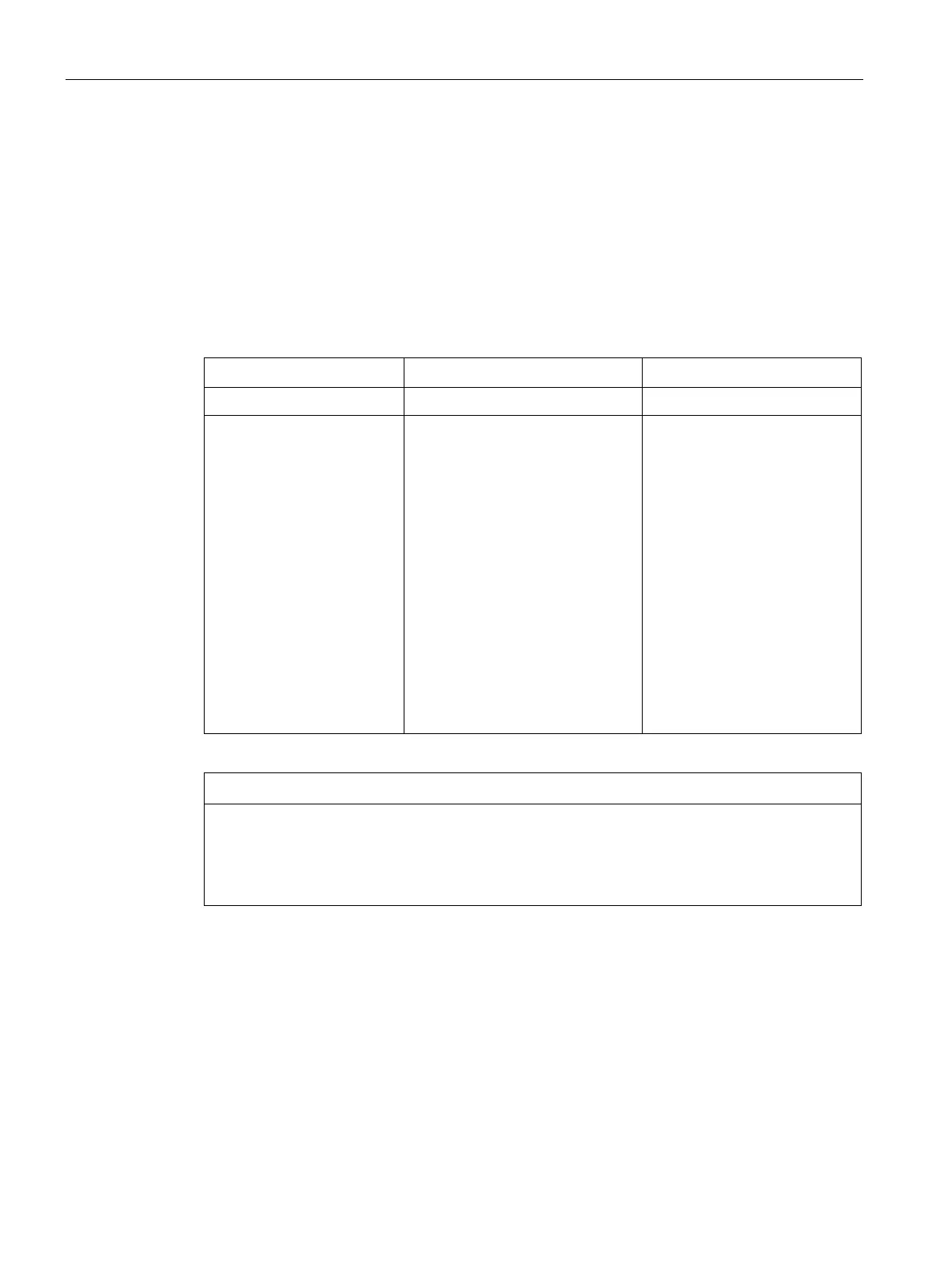

The type of holding brake installed depends on the size of the motor.

Type of the holding brake

installed in the motors 1FK2❑03 ... 1FK2❑04 1FK2❑05 ... 1FK2❑10

Method of operation The spring exerts a tensile force on

the brake armature disk. This

means that in the no-current condi-

tion, the brake is closed and the

motor shaft is held.

When 24 V DC rated voltage is

applied to the brake, the current-

carrying coil produces an opposing

field. This neutralizes the force of

the spring and the brake opens

without any residual torque.

The spring-loaded brake has a

torsional backlash less than 1°.

The magnetic field of the per-

manent magnets exerts a pull-

ing force on the brake armature

disk. This means that in the no-

current condition, the brake is

closed and the motor shaft is

held.

When 24 V DC rated voltage is

applied to the brake, the cur-

rent-carrying coil produces an

opposing field. This neutralizes

the force of the permanent

magnets and the brake opens

without any residual torque.

The permanent magnet brake

has a torsionally stiff connection

to the motor rotor.

Damage to the motor due to axial forces on the shaft extension

Axial forces on the shaft extension can damage motors with an integrated holding brake.

• Avoid impermissible forces on the shaft extension. Detailed information is provided in

Chapter "Axial forces (Page 32)".

● The holding brake is used to clamp the motor shaft when the motor is at a standstill. The

holding brake is

a working brake for braking the rotating motor. When the motor is at

a standstill, the holding brake is designed for at least 5 million switching cycles.

Loading...

Loading...