page 13808D turning and milling Service guide

If the fault is

:

The screen can display feed axis data, but the

actual machine cannot move.

车削与铣削

车削与铣削车削与铣削

车削与铣削 第

第第

第页

页页

页 服务指南

服务指南服务指南

服务指南

硬件故障

硬件故障硬件故障

硬件故障

服务案例

服务案例服务案例

服务案例

若故障为:机床实际移动方向与操作方向相反 / 机床实际移动方向

与屏幕显示方向相反

情况2

检查 V60 驱动器上的方向键连接线是否正确

端子 DR / DR 的接线与实际相比是否接反

检查机床数据 MD32100 / MD32110 设置是否正确

MD32100:轴反向键(默认值 =1,根据需要可调整为 1)

MD32110:编码器位置反馈极性键(默认值 =1,根据需要可调整为 1)

故障现象描述

故障现象描述故障现象描述

故障现象描述:

系统已完成回参考点状态

1.屏幕上有进给轴移动数值显示,但实际机械不动

2.机床实际移动方向与操作方向相反 / 机床实际移动方向与屏幕显示方向相反

进给轴故障

进给轴故障进给轴故障

进给轴故障

诊断步骤

如使用第三方驱动器,检查驱动器上是否存在报警

如果上述检查之后故障仍然存在,则很可能是系统主板 (PPU) 损坏,需要

进行更换或维修

检查机械上的联轴器是否松动

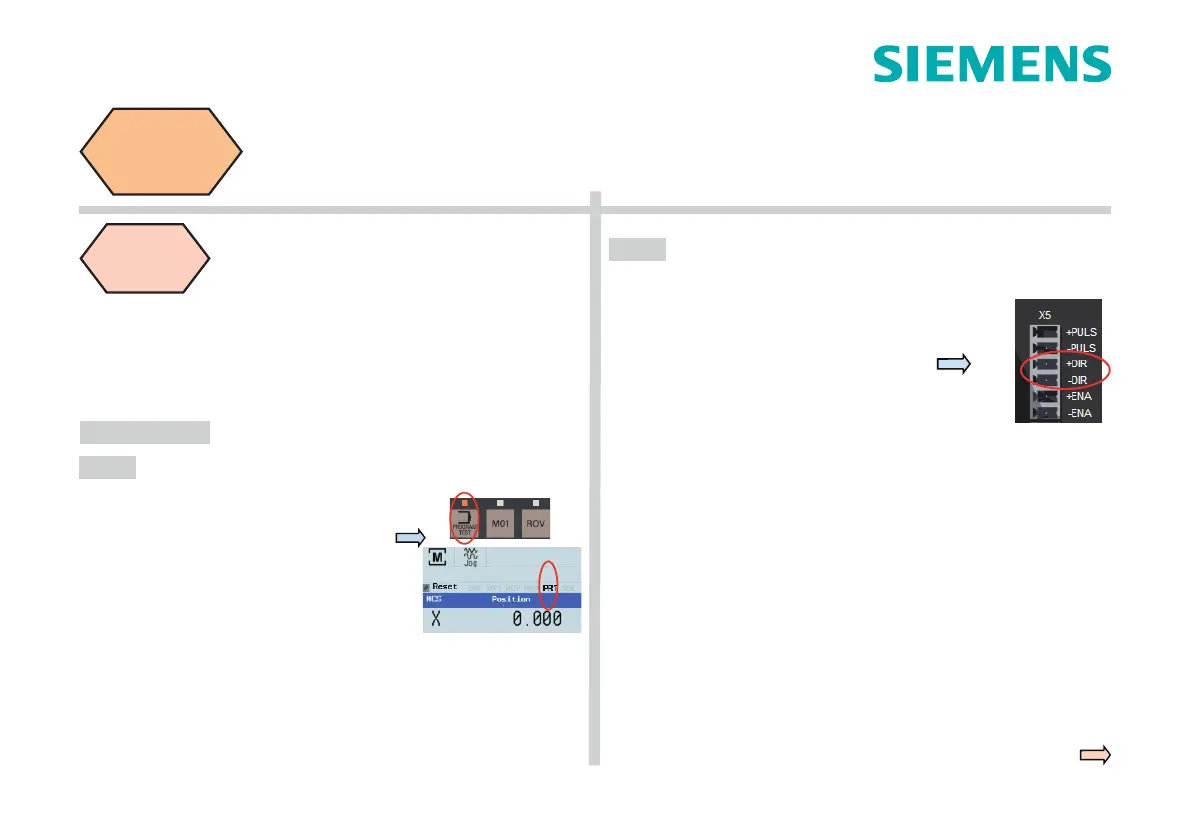

检查 PPU 上是否处于程序测试状态

1.MCP 上的“程序测试”按键指示灯是

否点亮(不可点亮)

2.PPU 屏幕上“PRT”指示符是否激活

(不可激活)

若故障为:屏幕上有进给轴移动数值显示,但实际机械不动

情况1

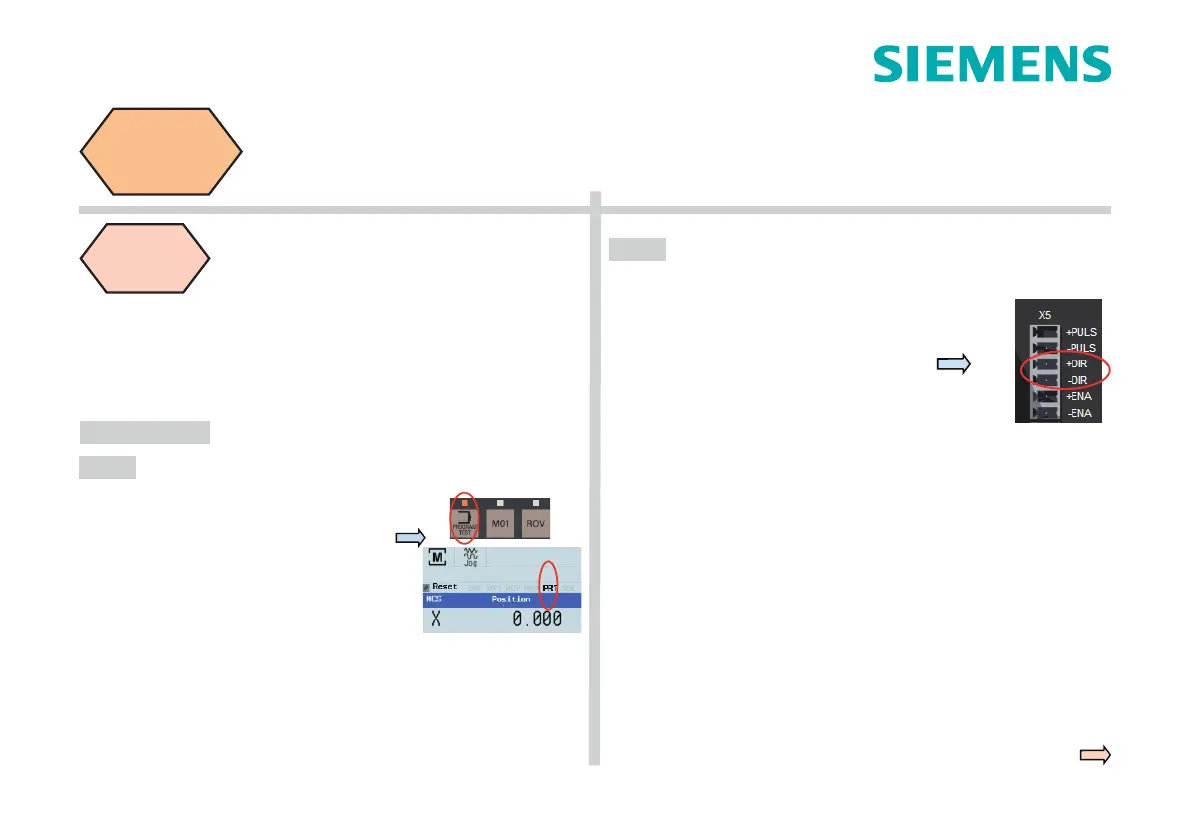

检查轴信号与驱动器连接是否良好:V60 驱动器上的端子是否插紧 / 损坏

Feed axis

fault

Please check whether the PPU is in the program

test state.

1. Whether the indicator light of the

"Program test" button on the MCP is on (it

should not be on).

2. Whether the "PRT" indicator on the PPU

screen is activated (it should not be activated).

Check whether the mechanical coupling is loose.

Check whether the connection between the axis signal and the drive is

good, and whether the pins on the V60

are tight/damaged.

Check whether there are alarms on the drive if using a third-party drive.

Replacement and maintenance are necessary if the fault still exists after the

above inspection, because it is probable that the PPU is damaged.

Check whether the connections of the direction

keys on the V60 drive are correct.

Check whether the wiring of terminal + DIR / -

DIR is correct depending on the actua

l situation.

Check whether the settings of machine data MD32100 / MD32110 are

correct.

MD32100

:

Axis reverse key (The implied value = 1. It is permitted to

change to -1 according to the actual situation.)

MD32110

:

Encoder position feedback polarity key (The implied value

= 1. It is permitted to change to -1 according to the actual situation.)

Diagnostic steps

Fault description:

The system has completed the state of returning to the reference point

1. The screen can display feed axis data, but the actual machine cannot move

2. The actual direction of motion is opposite to the operational direction of

the machine / is opposite to the direction of screen display.

Case1

Case2

If the fault is: The actual direction of motion is opposite to the

operational direction of the machine / is opposite to the direction

of screen display.

Service case

of hardware

fault

Loading...

Loading...