23

Neutral Adjustment

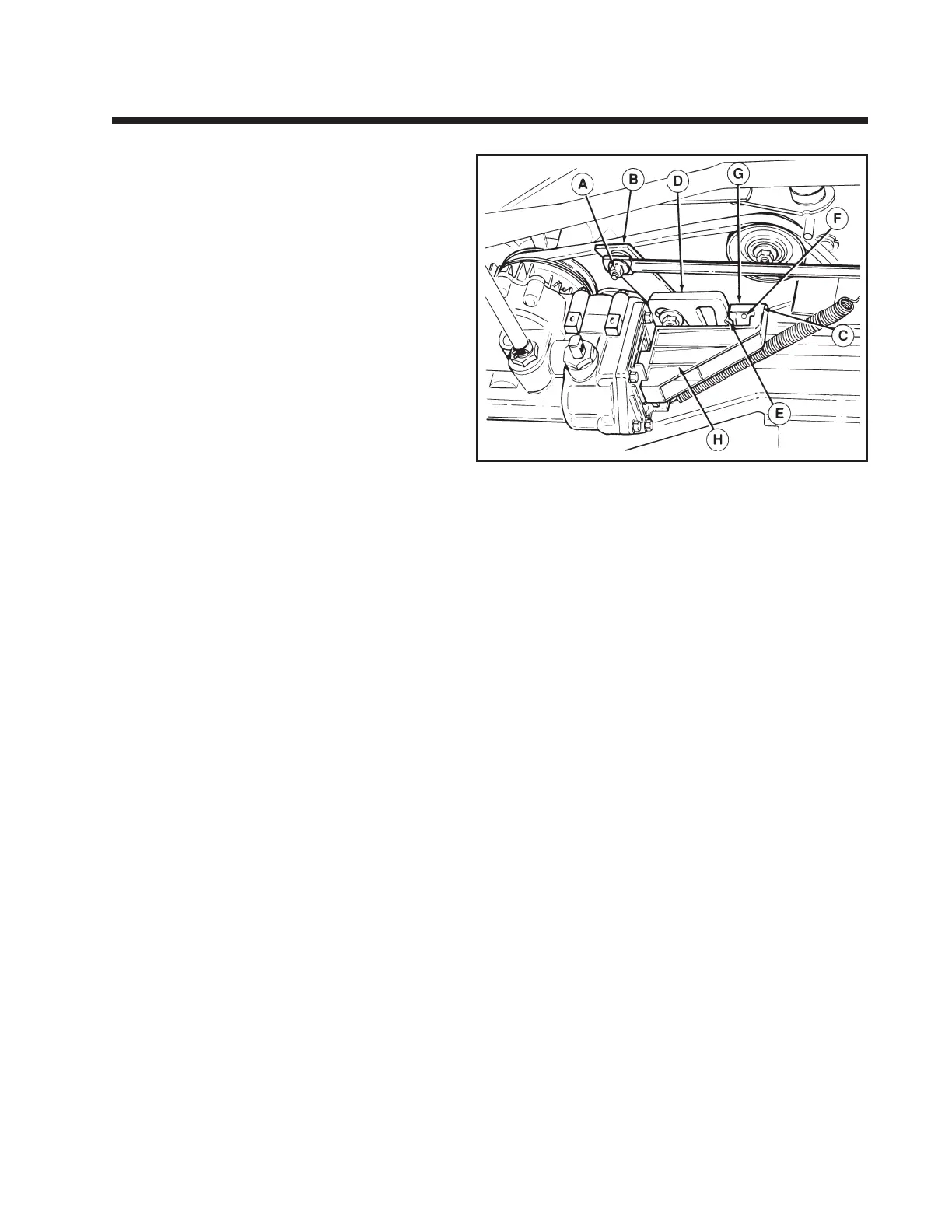

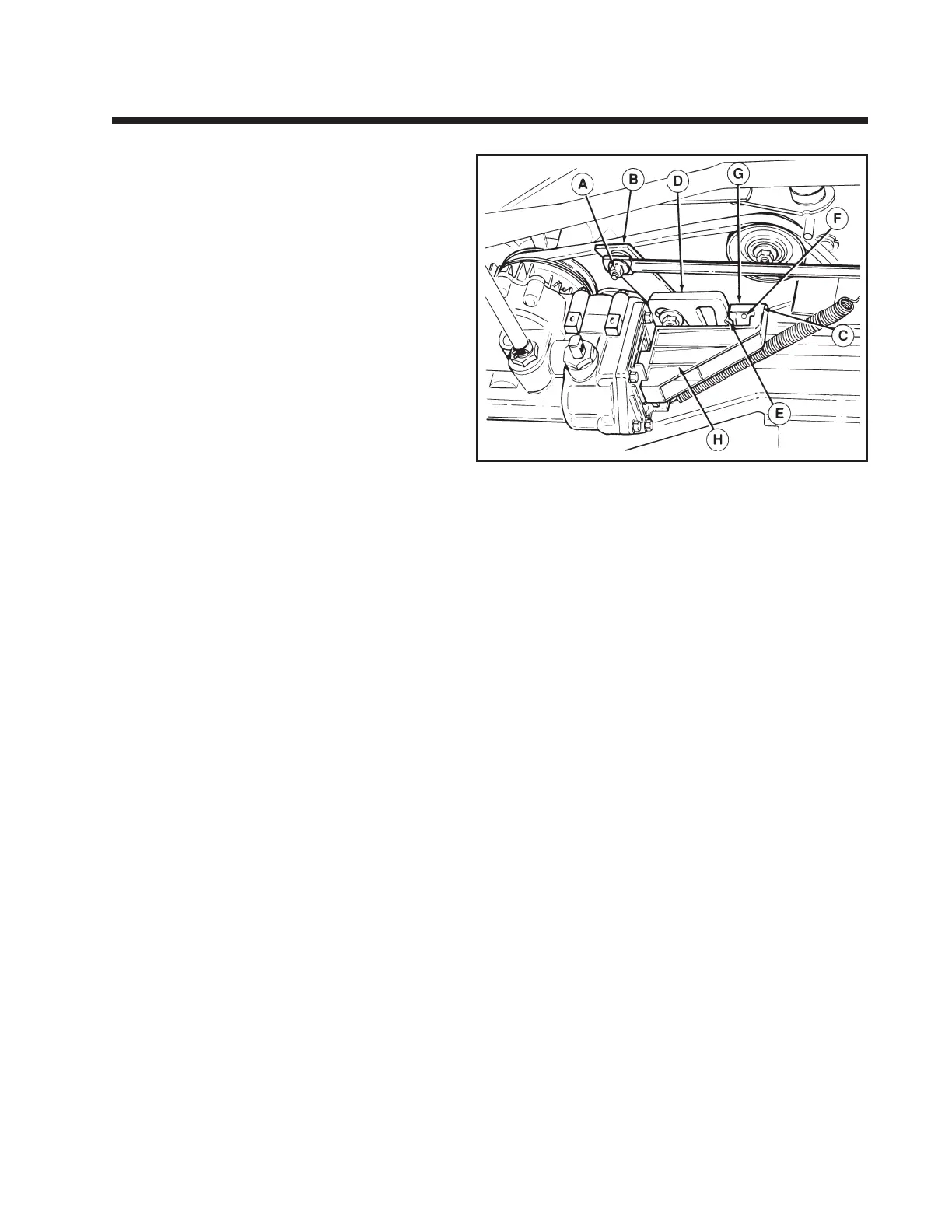

Later Models with Plastic Bracket (H, Figure 6-5)

1. Park tractor on level surface. Shut off PTO switch

and engine. Do not apply parking brake. Make

sure transmission control lever is in neutral and

has activated neutral switch light (ignition switch

on).

2. Raise rear of tractor off ground with a suitable

hoist or floor jack. Install jackstands underneath

transaxle and block front wheels.

3. Loosen nuts (A, figure 6-5) on both left side and

right side of speed control lever (B). (Left side nut

is located next to spring and not shown in

illustration.)

4. Loosen nut (C) securing ball retainer (G) to

plastic support bracket (H).

5. Rotate shift cam (D) so that neutral detent is

aligned with roller ball (E).

6. Start engine and increase to full throttle. If wheels

rotate, continue with adjustment. If wheels do not

rotate, go to step 8.

7. Place a 1/4- rod or #2 Phillips screwdriver into

hole (F) in eccentric ball retainer (G). Rotate ball

retainer until wheels stop moving.

8. Tighten nut (C) securing ball retainer (G).

9. Shut off engine and make sure dash transmission

control lever is in neutral position, and has

activated neutral light (Ignition switch on).

10. Pull right end of speed control lever (B) fully

forward. Tighten the left side 1/4" nut (not

shown).

11. Push the right end of speed control lever (B) fully

rearward and tighten right side 5/16" nut (A).

12. Check the "Return-To-Neutral" by following these

steps:

a. Shift transmission lever into forward (drive)

position and fully depress clutch/brake pedal.

b. Lever should return to neutral slot.

c. If lever does not return to neutral, repeat above

steps 1-11.

13. Remove tractor from jackstands.

Figure 6-5.

A. Nut

B. Speed Control Lever

C. Nut

D. Shift Cam

E. Roller Ball

F. Adjustment Hole

G. Eccentric Ball Retainer

H. Support Bracket (Plastic)

For early models with welded support bracket see page 21.

Section 6. (Continued)

Lawn Tractors with Eaton 750 Hydrostatic Transaxle

Loading...

Loading...