— 8 —

SECTION 4

MECHANICAL ADJUSTMENT

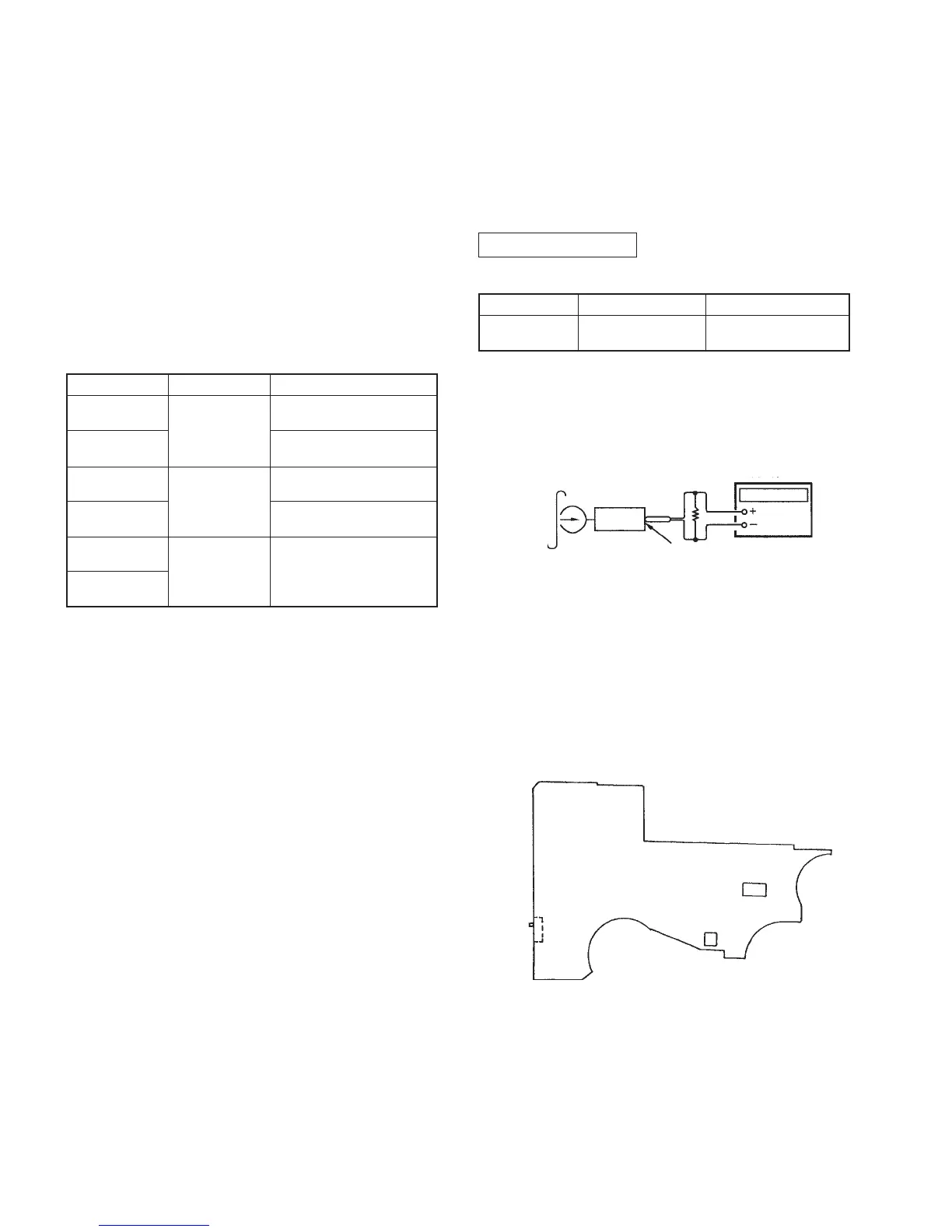

Mode

FWD

Torque Meter Meter Reading

FWD

Back tension

REV

REV

Back tension

CQ-102RC

CQ-102C

CQ-201B

FF

REW

18 — 33 g • cm

0.5 — 3.0 g • cm

18 — 33 g • cm

0.5 — 3 g • cm

More than 40 g • cm

SECTION 5

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Before adjusting, clean the following parts with a piece of

cotton moistened with alcohol.

REC/PB head pinch roller

rubber belt capstan

2. Demagnetize the playback head using a head

demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (1.3V)

to perform the adjustments.

[Torque Measurement]

PRECAUTION

1. Specified voltage : 1.3V.

2. Switch position

DOLBY NR switch : OFF

MEGA BASS switch: NORM

AVLS : OFF

CASSETTE SECTION

Test tape

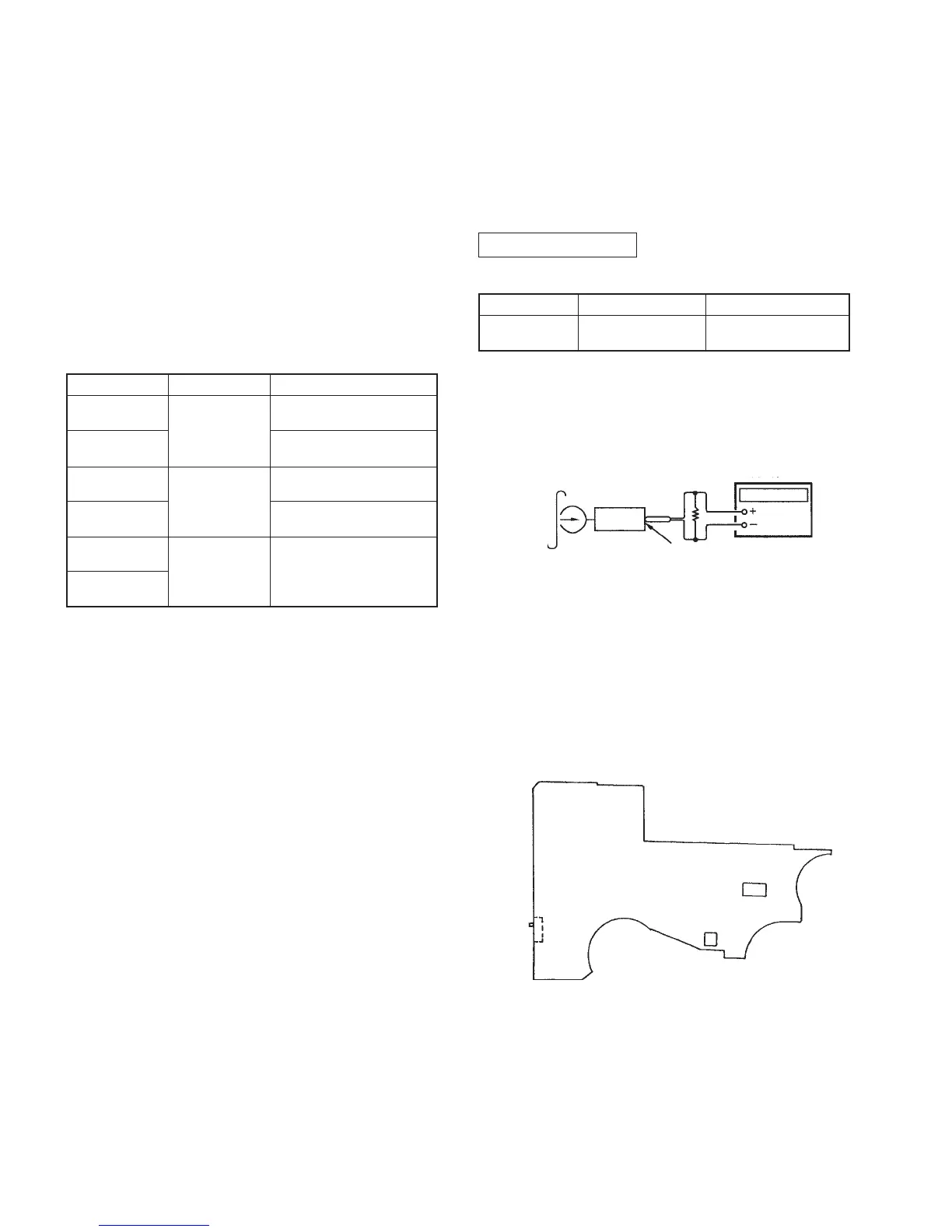

[Tape Speed Adjustment]

Procedure :

1. Playback WS-48A (tape center part) in the FWD state and

adjust RV601 so that the frequency counter reading

becomes 3000 ± 10 Hz.

2. Playback WS-48A (tape center) in the REV state.

Check that the frequency counter reading is within 2.5%

of the reading of step 1.

Adjustment Point :

[MAIN BOARD] — Side A —

Test tape

WS-48A

(3kHz, 0dB)

PHONES jack

3 kHz, 0 dB

Tape Speed AdjustmentWS-48A

RV601

frequency

counter

S714

(HOLD)

Type

Signal Used for

IC601

set

16

Loading...

Loading...