-

-

-

hazard.

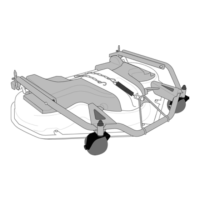

11. Take hold of the front cutting-means as-

sembly edge and lift. Continue lifting until

the cutting-means assembly is completely

vertical and rest the back end on the ground.

See g. 25.

12. Restore the cutting-means assembly to its

original position as specied in heading 5.2.3

from point 9 onwards.

8.4 CLEANING

Always clean the bottom part of the

Take care over the sharp blades. Wear

protective gloves.

Set the cutting-means assembly to the washing

position.

Clean the bottom of the cutting-means assembly

with great care using only water and a brush.

If during use any of the paintwork has got

scratched or come o, touch up when the surfa-

ces are completely clean and dry.

Use non-perishable yellow paint for outdoor appli-

cations which is suitable for metal.

8.5 CUTTING MEANS (21:A)

8.5.1

The cutting-means assembly is tted with a

number of safety devices which reduce the risk

of damaging the cutting-means assembly and

the drive system should the same hit an obstacle

while in motion.

These devices are:

• Shear bolts (14:C) which secure the cutting

means (14:A) to the cutting means holder bar

(14:B),

• Torque limiter for cutting-means assembly drive

shaft transmission.

• possibility for positive drive belt slipping over the

plastic gearwheels.

8.5.2

Wear protective gloves.

Check that the cutting-means assembly is always

perfectly sharpened.

This is essential for obtaining optimum results.

year

an impact, replace them if damaged.

-

stance service.

same holder bar to avoid loss of correct

balance.

which can be installed on the machine,

-

ne.

Re-assemble the cutting means as follows:

• Install the cutting means (14:A) on the cutting

means holder bar (14:B) using the relative

screws (14: C and D).

• Install the cutting means hold bar on its support

(14:E).

• The cutting-means assembly can be turned

1/3 of a turn on their supports. Synchronize the

cutting-means assembly so that they are at a

90° angle to one another. See heading 7.5.3

Cutting means xing screws tightening torque:

• Screw (14:F): 45 Nm

• Screws (14:D): 45 Nm

• Shear bolts (14:C) 9.8 Nm

In the event of collision, the shear bolts (14:C) may

snap.

If this occurs, install new, genuine shear bolts and

tighten to the torque indicated.

8.5.3

The cutting-means assembly are correctly syn-

chronized when their axes are set at a 90° angle to

one another. See Fig. 21

Synchronization may be lost if the cutting means

hit an obstacle with the resulting risk of interferen-

ce.

Loading...

Loading...