STIHL 064, 066 45

5. IGNITION SYSTEM

Warning! Exercise extreme caution when

carrying out maintenance and repair work

on the ignition system. The high voltages

which occur can cause serious or even

fatal accidents!

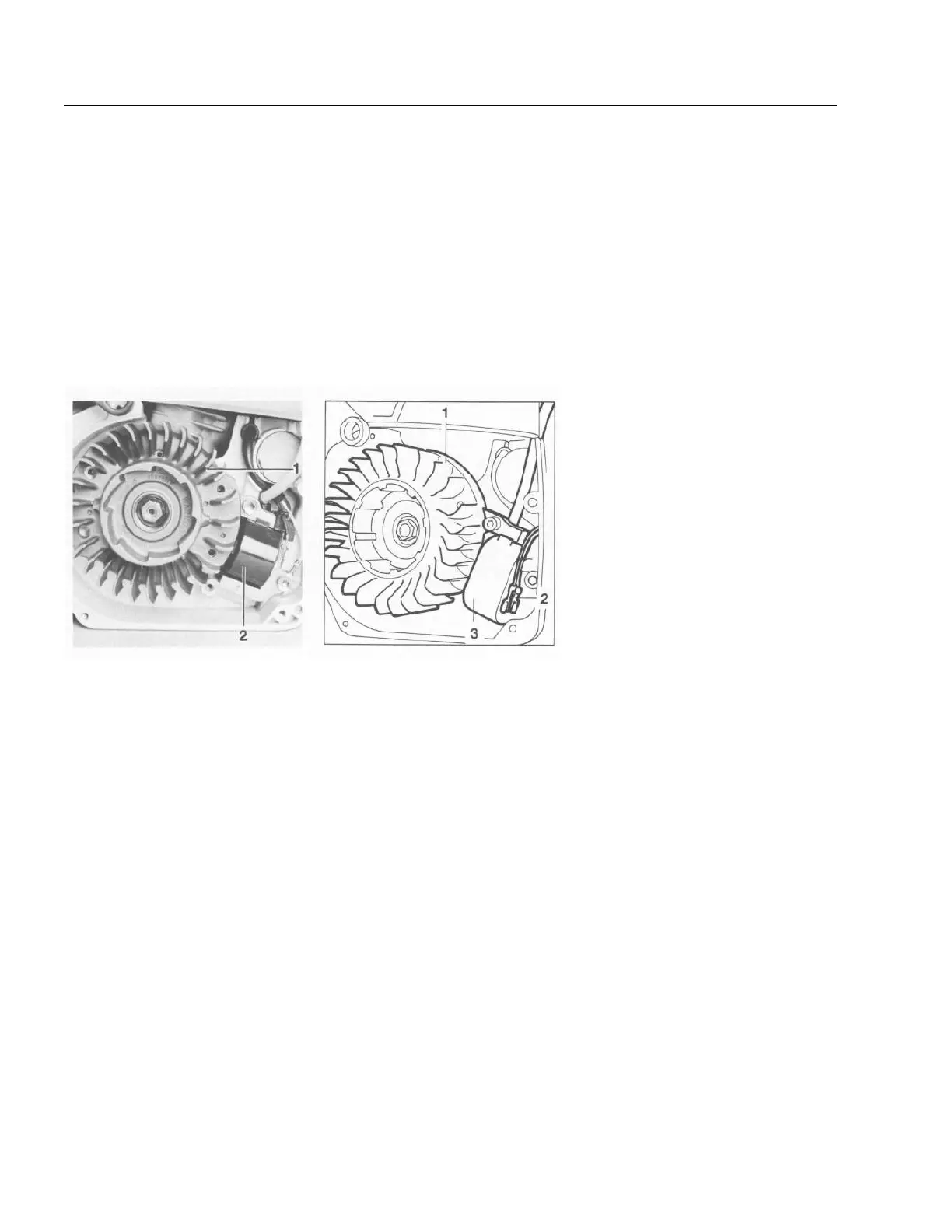

1 = Flywheel

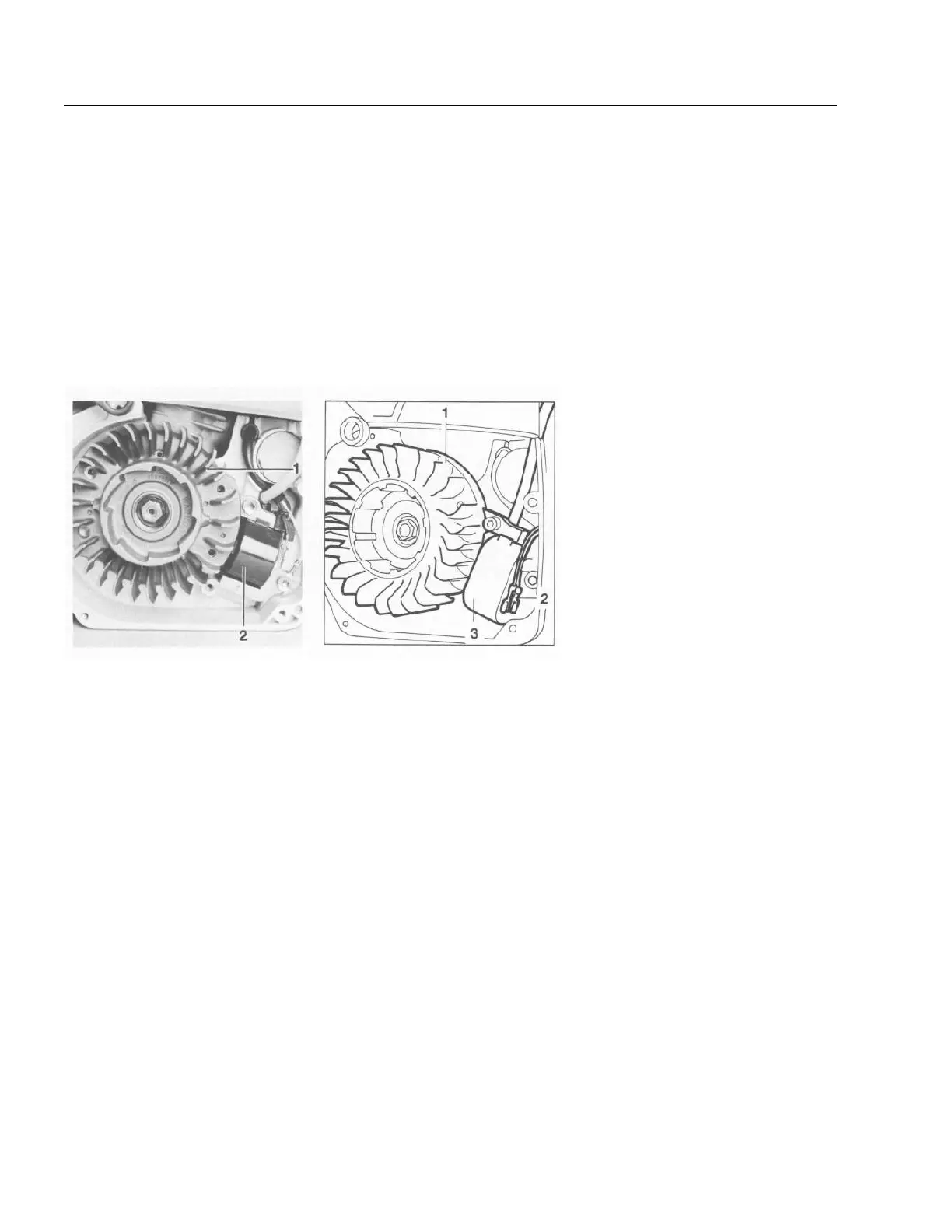

1 = Flywheel 2 = Wire for LED (066 only)

2 = I

nition module 3 = I

nition module

di

ital

CDIC and CDIC A digital ignition modules

feature an electronic cut-in threshold to

prevent backfiring during engine starts. An

ignition spark is generated only if the

cranking speed of the crankshaft is high

enough for its mass moment of inertia to

overcome combustion pressure.

Cut-in threshold:

CDIC ignition module (064) =

1,200 rpm

CDIC A ignition module (066) =

500 rpm

Older STIHL 064 saws are Model 064 saws from machine When using the spark test to

equipped with a transistor-control- number X 18 761 250 are check installed digital ignition

led electronic (breakerless) magne- equipped with an electronic digital modules with the sprark plug un-

to ignition system which requires ignition which features a maximum screwed, make sure that the star-

no outside power source (battery speed governor and requires no ter rope is pulled at a sufficiently

or dynamo). outside power source. high speed. If there is no spark at

the plug when the starter is pulled,

The system consists basically of The STIHL 066 is also equipped repeat the test at a higher cranking

an ignition module and flywheel with an electronic digital ignition speed.

and is easily accessible. with a maximum speed governor.

Note: A special flywheel is in- The ignition module installed in the

stalled in models with heated 066 has a second connection for a

handles (with ring magnet for the light emitting diode (LED) which

generator). aids carburetor adjustment.

Analog ignition systems can be In the digital ignition system the

converted to a digital system. This zero values of the magnetic flux

necesitates changing the flywheel in the magnetic field between the

and carburetor. flywheel and ignition module yoke

are evaluated to determine ignition

timing. This means that ignition

timing is tied to fixed physical

values and can be varied only by

the electronically stored advance

curve as a function of engine

speed.

Loading...

Loading...