Important: The electrical safety of

the saws should be checked after

every repair by performingahigh-

voltage insulation test. Tests of

this kind may only be carried out

by electricians or specially trained

personnel.

Always unplug the machine from

the mains supply.

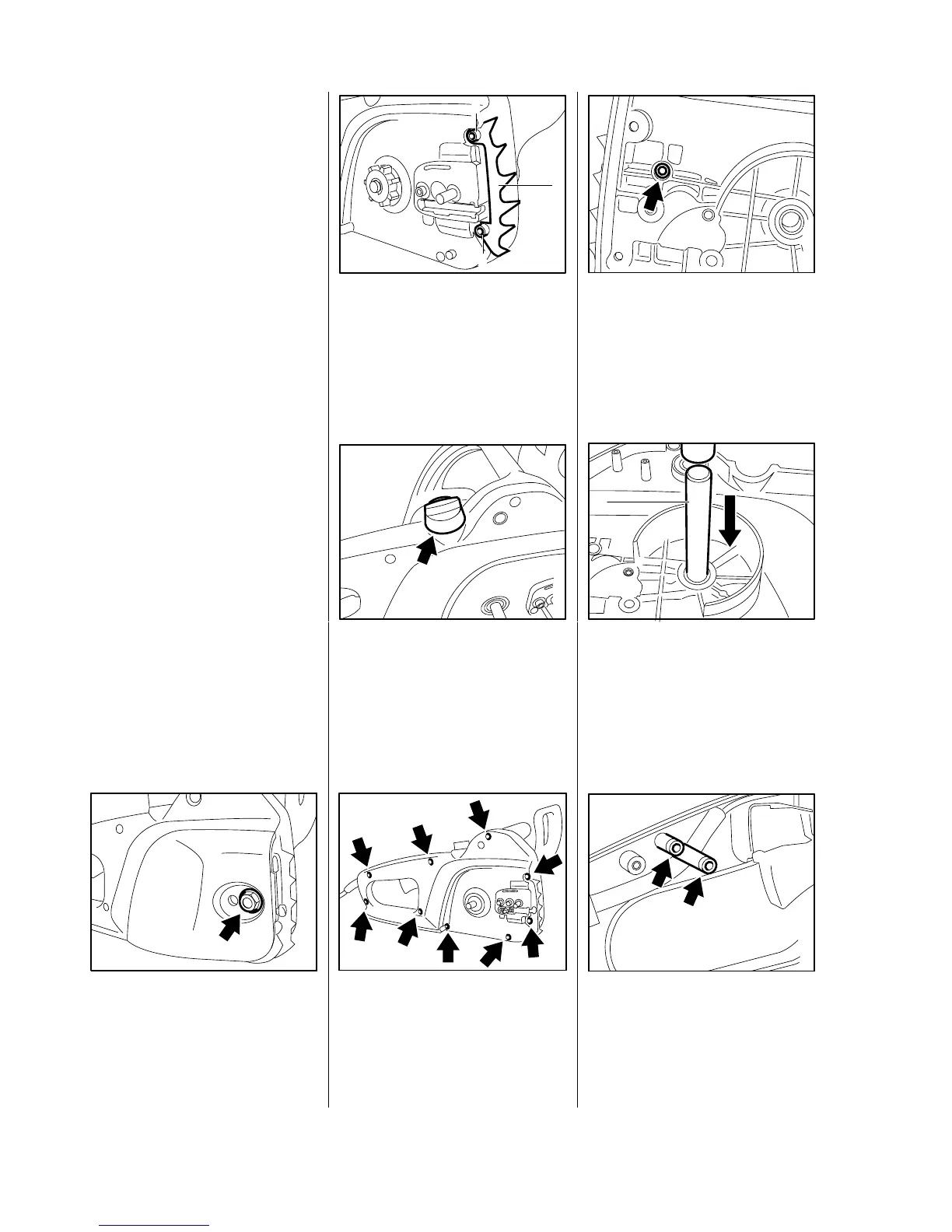

- Remove the quick chain

tensioner, if fitted - see 7.3.

•

Unscrew nut.

- Remove the chain sprocket

cover.

Models with quick chain

tensioner

•

Take out screws (1).

•

Remove the spiked bumper (2).

All models

- Remove the chain sprocket -

see 6.1.

•

Unscrew oil filler cap and remo-

ve together with cap retainer.

•

Take out the screws.

- Remove the handle housing.

•

Take out the O-ring.

- Placeasocket (e.g. 19mm)

under the handle housing so that

it supports the bearing bush from

outside.

•

Use drift (1) 1111 893 4700 to

press needle sleeve out of

bearing bush.

•

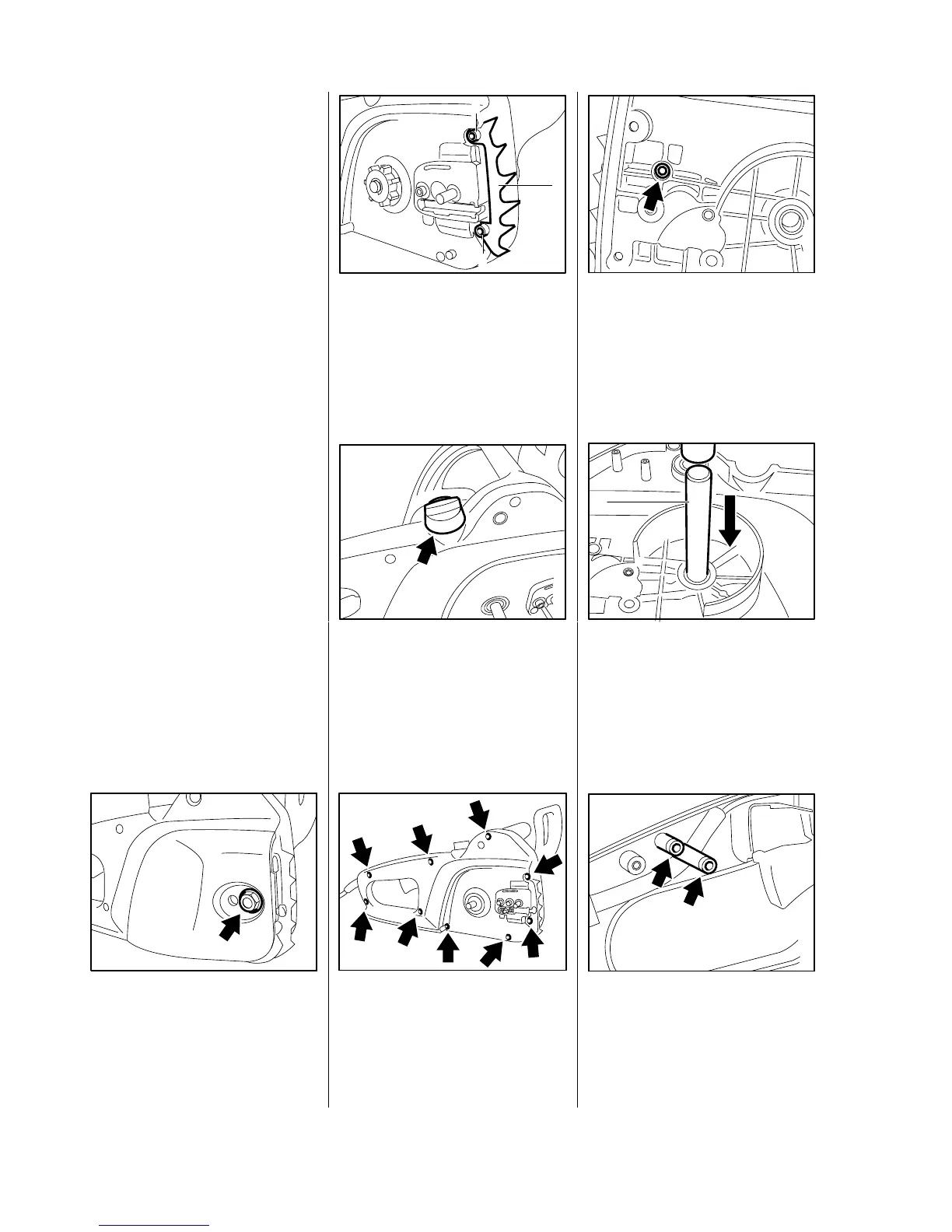

Take out the screws.

- Remove the strain relief cable

clamp.

100RA005

VA

100RA008

1

VA

100RA004

2

1

1

VA

100RA003

VA

4. Removing and Installing Electrical Components

4.1 Connecting Cord

100RA007

VA

100RA006

VA

100RA009

VA

6

Loading...

Loading...