'XULQJEUHDNLQSHULRG

A factory new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period.

As all moving parts have to bed in

during the break-in period, the

frictional resistances in the engine

are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

'XULQJRSHUDWLRQ

After a long period of full-throttle

operation, allow engine to run for a while

at idle speed so that the heat in the

engine can be dissipated by flow of

cooling air. This protects engine-

mounted components (ignition,

carburetor) from thermal overload.

$IWHUILQLVKLQJZRUN

Wait for engine to cool down. Drain the

fuel tank. Store the machine in a dry

place. Check tightness of nuts and

srews (not adjusting screws) at regular

intervals and retighten as necessary.

*HQHUDO1RWHVRQ2SHUDWLRQ

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and

unfavorable running conditions (mostly

at part throttle etc.) affect the condition of

the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

If engine is down on power, difficult to

start or runs poorly at idling speed,

first check the spark plug.

•

Remove spark plug -

see chapter “Starting”:

•

Clean dirty spark plug.

•

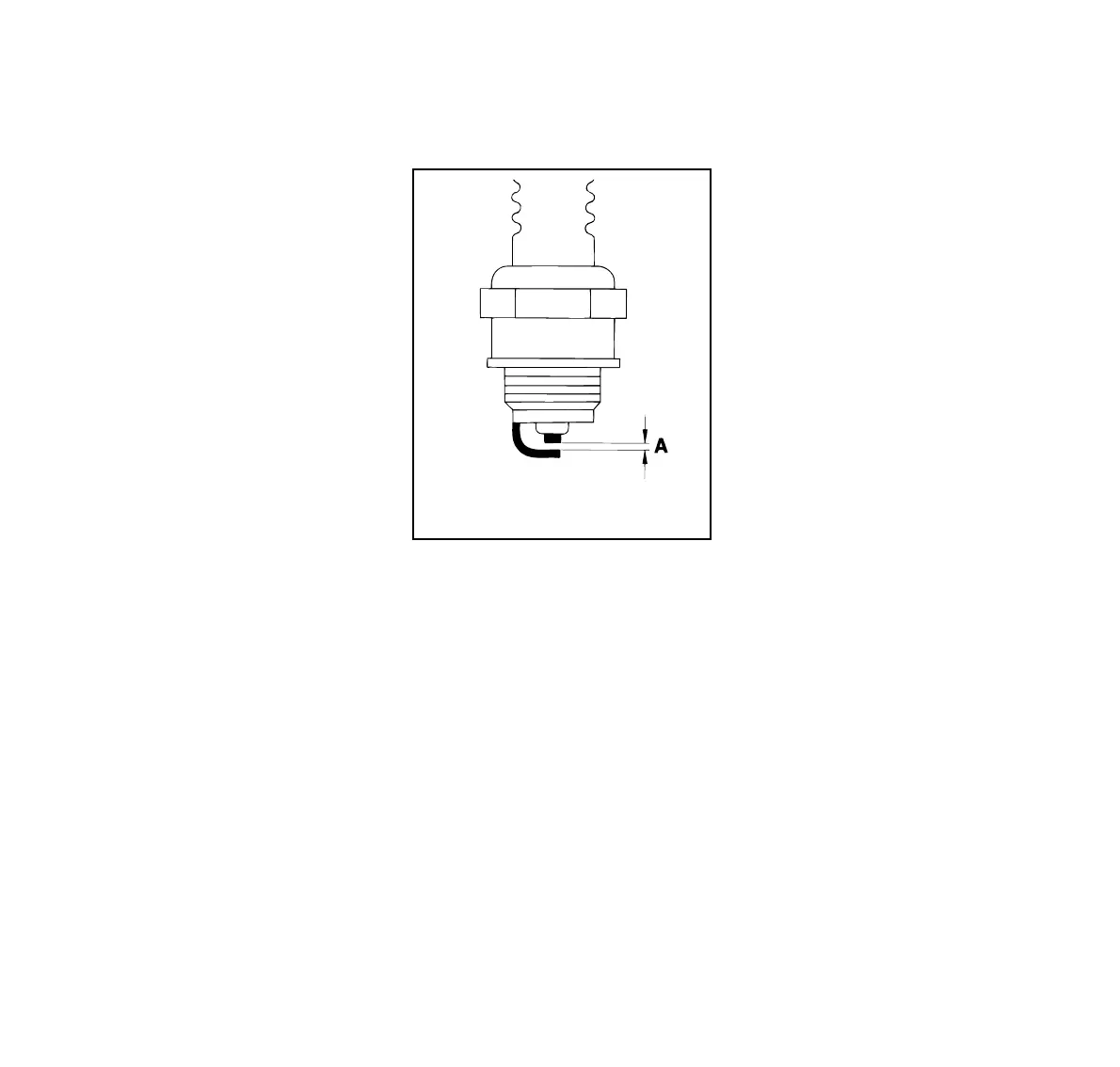

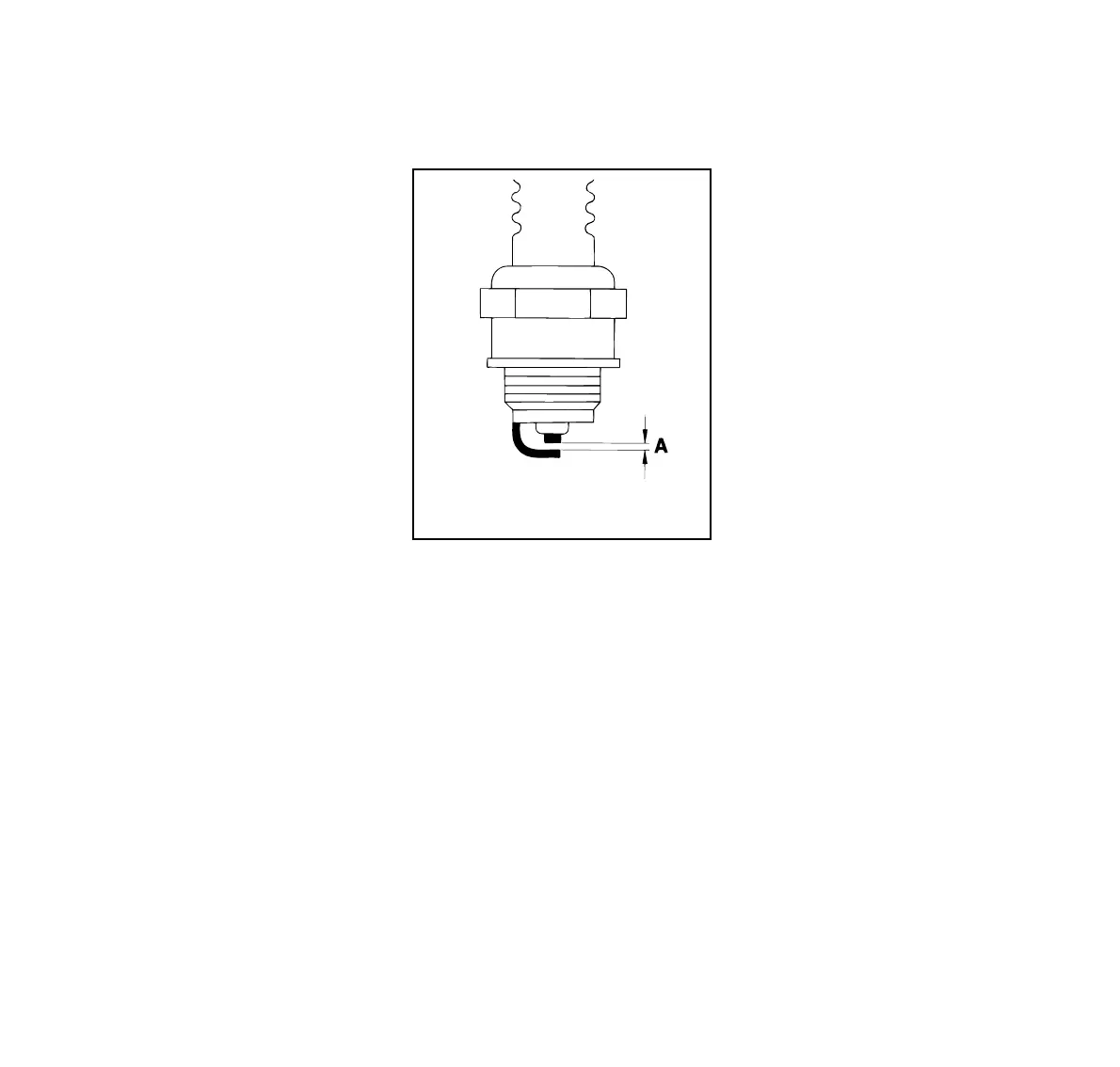

Check electrode gap -

it should be 0.7mm/0.03" $ -

readjust if necessary.

•

Use only resistor type spark plugs

of the approved range.

Rectify problems which have caused

fouling of spark plug:

Incorrect carburetor setting, too much oil

in fuel mix, dirty air filter,

unfavorable running conditions, e.g.

operating at part load.

•

Fit a new spark plug after

approx. 50 operating hours -

or earlier if the electrodes are

badly eroded.

:DUQLQJ

To reduce the risk of fire and burn injury,

use only spark plugs authorized by

STIHL (see “Specifications”).

000BA002 KN

&KHFNLQJ6SDUN3OXJ

)6

Loading...

Loading...