MS 241 C-M

English

39

Varying cutting lengths, types of wood

and work techniques require varying

amounts of oil.

The oil flow can be adjusted as needed

using the adjusting screw (1) (on the

bottom of the machine).

Ematic position (E), medium oil flow –

N Turn adjusting screw to E (Ematic

position)

To increase oil flow –

N turn the adjusting screw clockwise

To reduce oil flow –

N turn the adjusting screw

counterclockwise

NOTICE

The saw chain must always be coated

with oil.

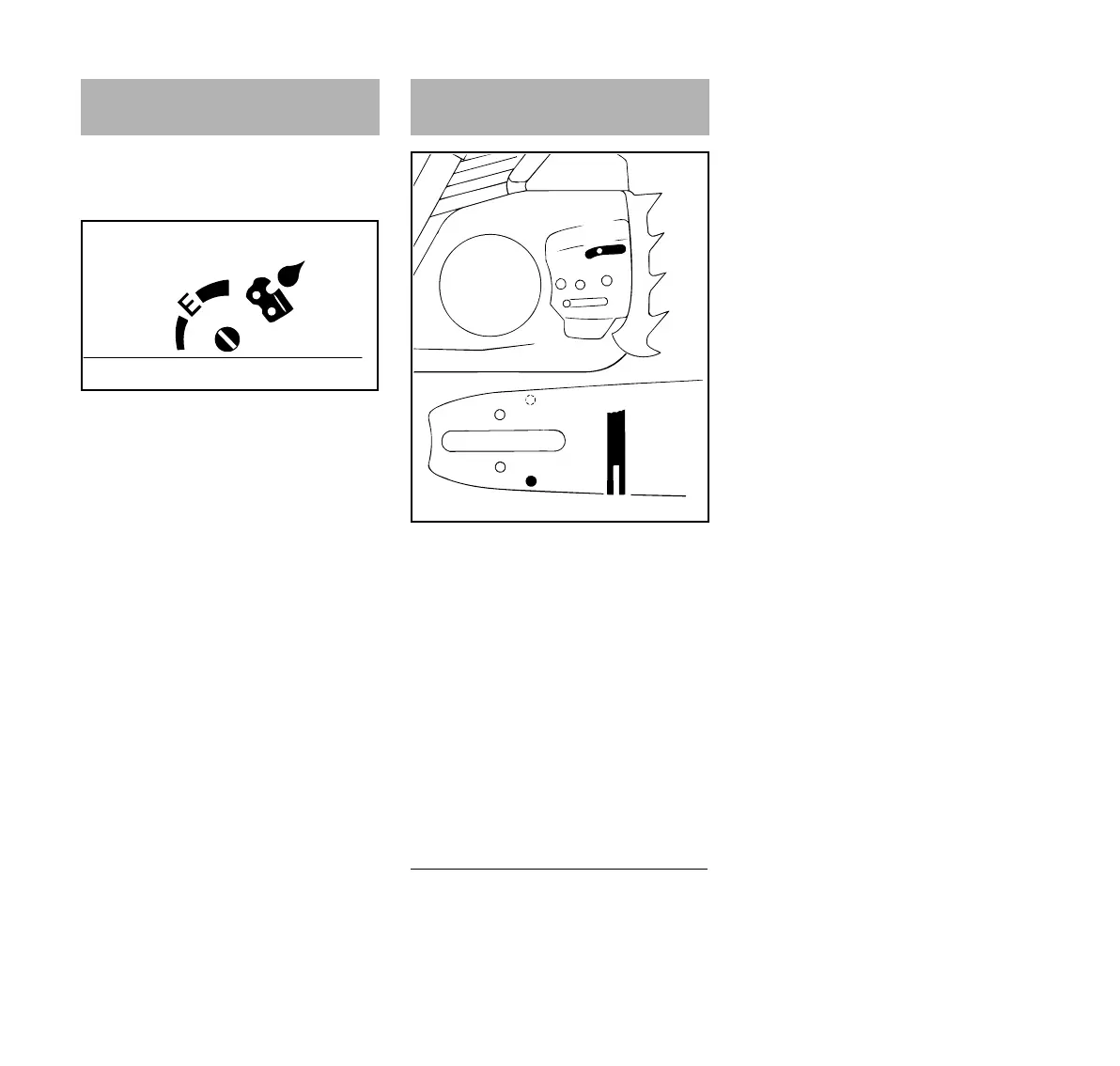

N Turn the guide bar over – every time

you sharpen the chain and every

time you replace the chain – this

helps avoid one-sided wear,

especially at the nose and

underside of the bar.

N Regularly clean the oil inlet hole (1),

the oilway (2) and the bar groove

(3).

N Measure the groove depth – with the

scale on the filing gauge (special

accessory) – in the area used most

for cutting.

If groove depth is less than specified:

N Replace the guide bar.

The drive link tangs will otherwise

scrape along the bottom of the groove –

the cutters and tie straps will not ride on

the bar rails.

Oil Quantity Control

Taking Care of the Guide Bar

Chain

type

Chain pitch Minimum

groove depth

Picco 1/4" P 0.16" (4.0 mm)

Rapid 1/4" 0.16" (4.0 mm)

Picco 3/8" P 0.20" (5.0 mm)

Rapid 3/8"; 0.325" 0.24" (6.0 mm)

Rapid 0.404" 0.28" (7.0 mm)

Loading...

Loading...