38

English / USA

MSE 140 C, MSE 160 C, MSE 180 C, MSE 200 C

Furthermore, the angles must be the

same on all cutters. If angles are uneven

the chain will run roughly, not in a

straight line, wear quickly and break

prematurely.

As these requirements can be met only

after sufficient and constant practice:

: Use a file holder

Always use a file holder for manual

resharpening chains (special accessory

– see Table "Sharpening Tools"). The

correct filing angle is marked on the file

holder.

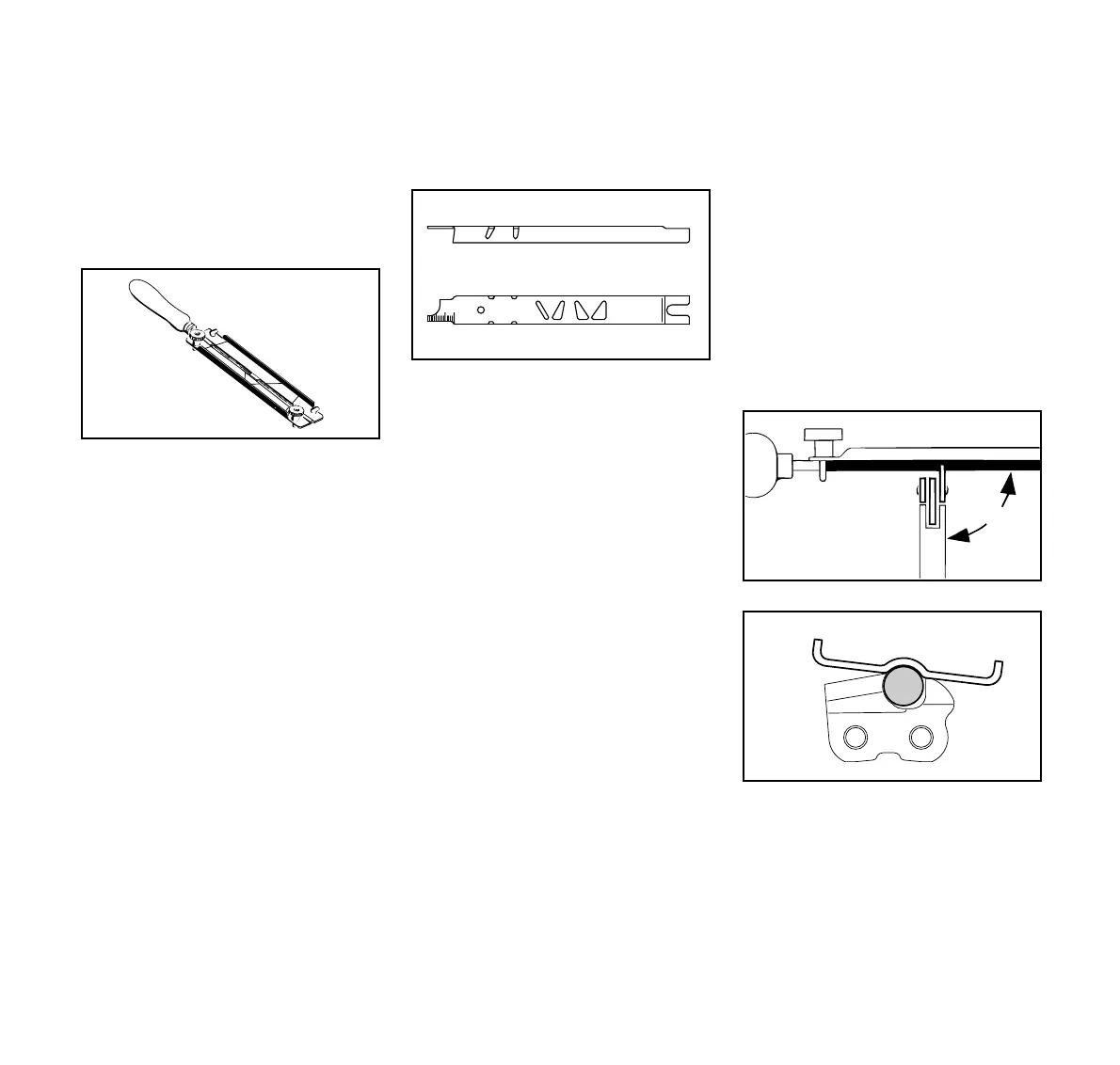

For checking angles

Use a STlHL filing gauge (special

accessory – see table "Sharpening

Tools"). This is a universal tool for

checking the filing and side plate angles,

depth gauge setting and cutter length. It

also cleans the guide bar groove and oil

inlet hole.

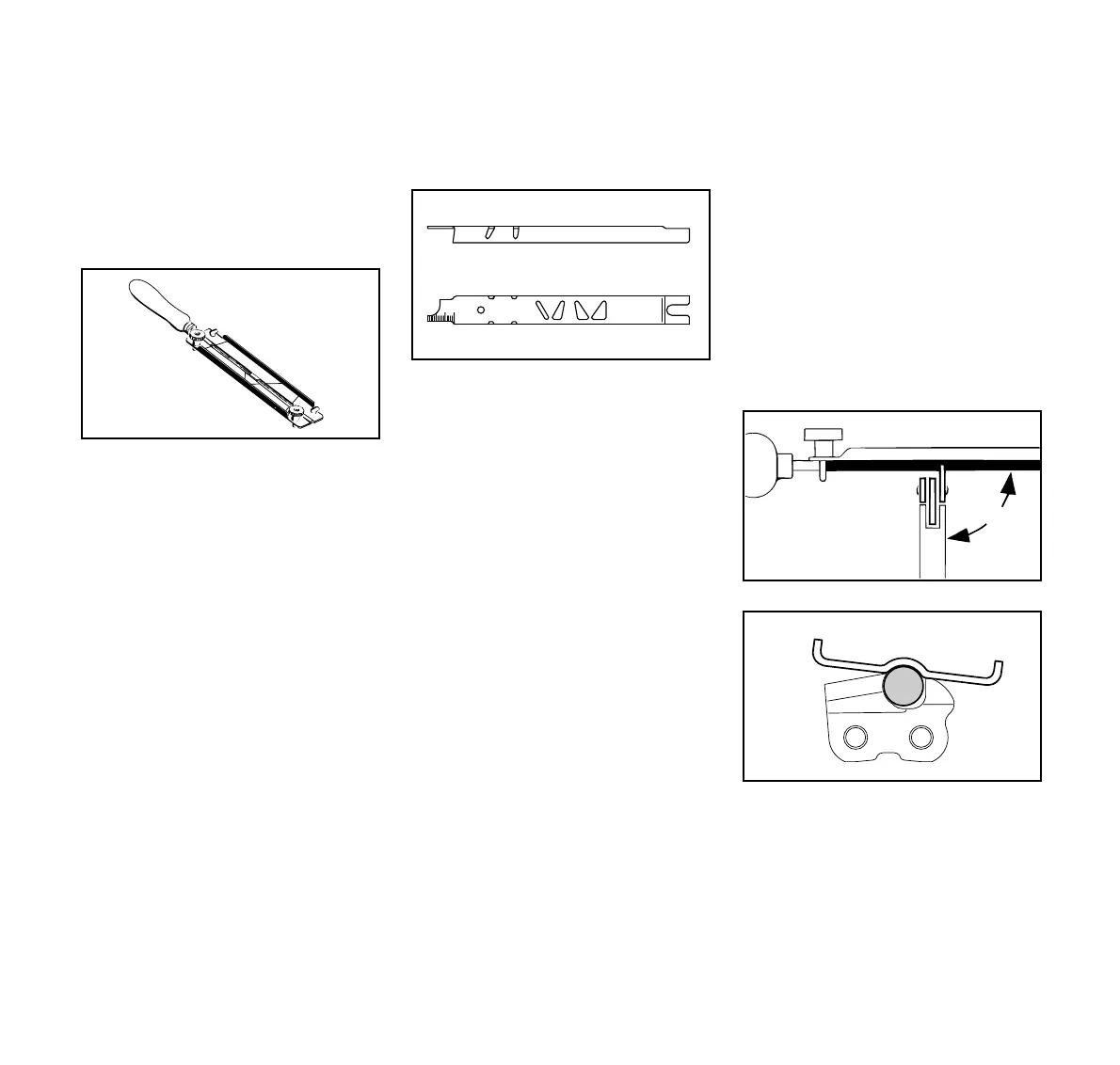

File correctly

: Disconnect plug from power

supply.

: Select sharpening tools to suit the

chain pitch.

: Clamp the bar in a vise if necessary.

: Lock the chain in position by

engaging the chain brake –

push the hand guard forwards.

: To move the chain along the bar,

disengage the chain brake by

pulling the hand guard towards the

front handle.

On models MSE 140 C, MSE 160 C,

MSE 180 C and MSE 200 C:

Hold the hand guard in this position

to deactivate the coasting brake.

: Sharpen the chain frequently; take

away as little metal as possible –

two or three strokes of the file are

usually enough.

689BA025 KN

90°

60°

85° 70°

80°

0°

35°

10°

30°

689BA022 KN

689BA018 KN

90°

689BA043 KN

Loading...

Loading...