18 SR 430, SR 450

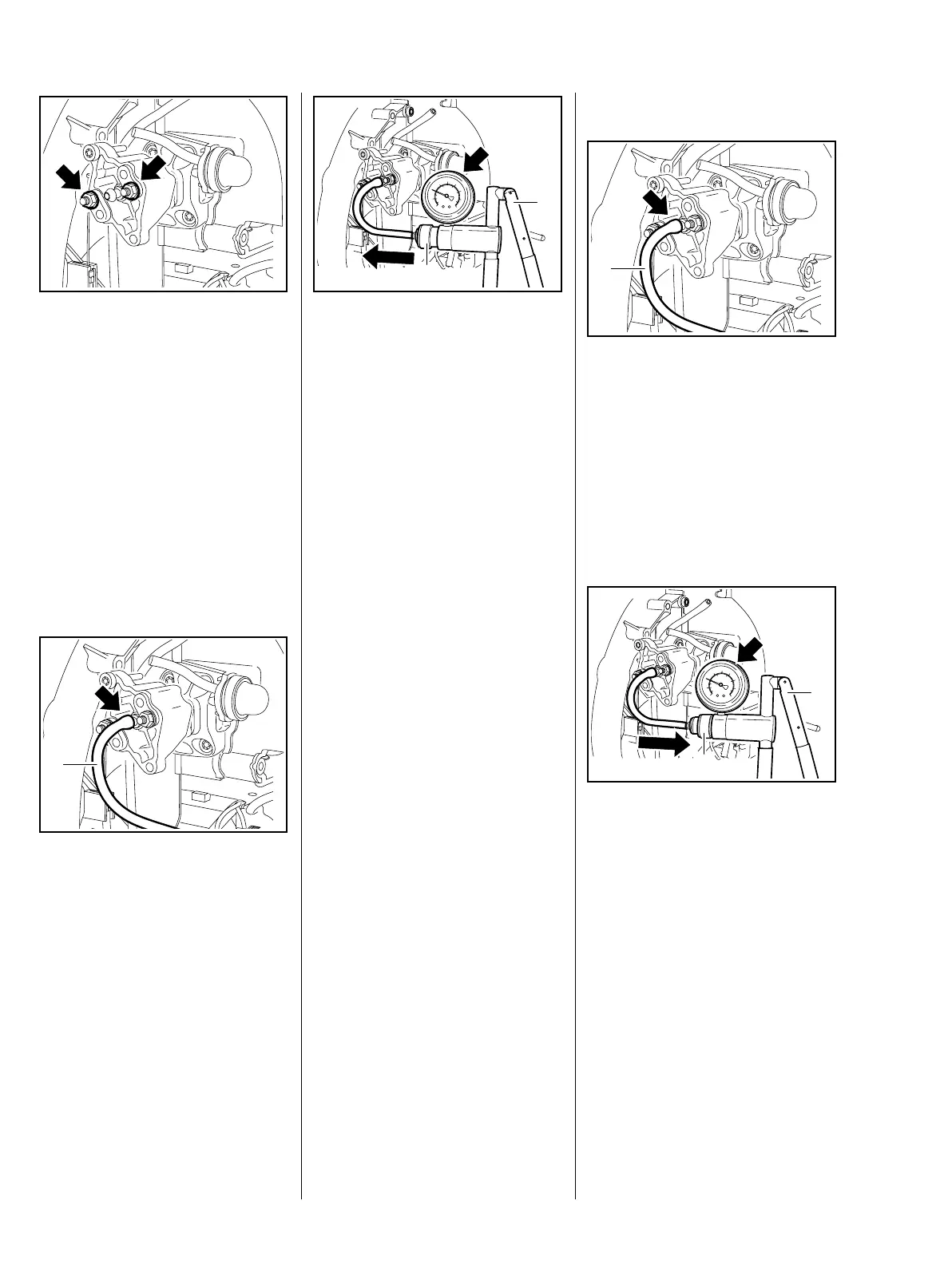

: Fit the nuts (arrows) and tighten

them down firmly.

4.2.2 Vacuum Test

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston's induction stroke because

there is no internal counterpressure.

A test can be carried out with pump

0000 850 1300 to detect this kind of

fault.

: Connect pressure hose (1) of

pump 0000 850 1300 to the

nipple (arrow).

0002RA015 TG0002RA016 TG

1

: Push ring (1) to the left.

: Operate the lever (2) until the

pressure gauge (arrow) indicates

a vacuum of 0.5 bar.

If the vacuum reading remains

constant, or rises to no more than

0.3 bar within 20 seconds, it can be

assumed that the oil seals are in

good condition.

However, if the pressure continues

to rise (reduced vacuum in the

engine), the oil seals must be

replaced, b 4.3.

– After finishing the test, push the

ring to the right to vent the pump.

– Continue with pressure test,

b 4.2.3

1

2

0002RA017 TG

4.2.3 Pressure Test

Carry out the same preparations as

for the vacuum test, b 4.2.2

– Always carry out the pressure

test after the vacuum test,

b 4.2.2

: Connect pressure hose (1) of

pump 0000 850 1300 to the

nipple (arrow).

: Push ring (1) to the right.

: Operate the lever (2) until the

pressure gauge (arrow) indicates

a pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the engine is

airtight.

– If the pressure drops, the leak

must be located and the faulty

part replaced.

0002RA016 TG

1

1

2

0002RA018 TG