6-6 CYLINDER, PISTON AND EXHAUST VALVE

• Inspect for cylinder distortion.

Cylinder distortion

Service Limit: 0.05 mm (0.002 in)

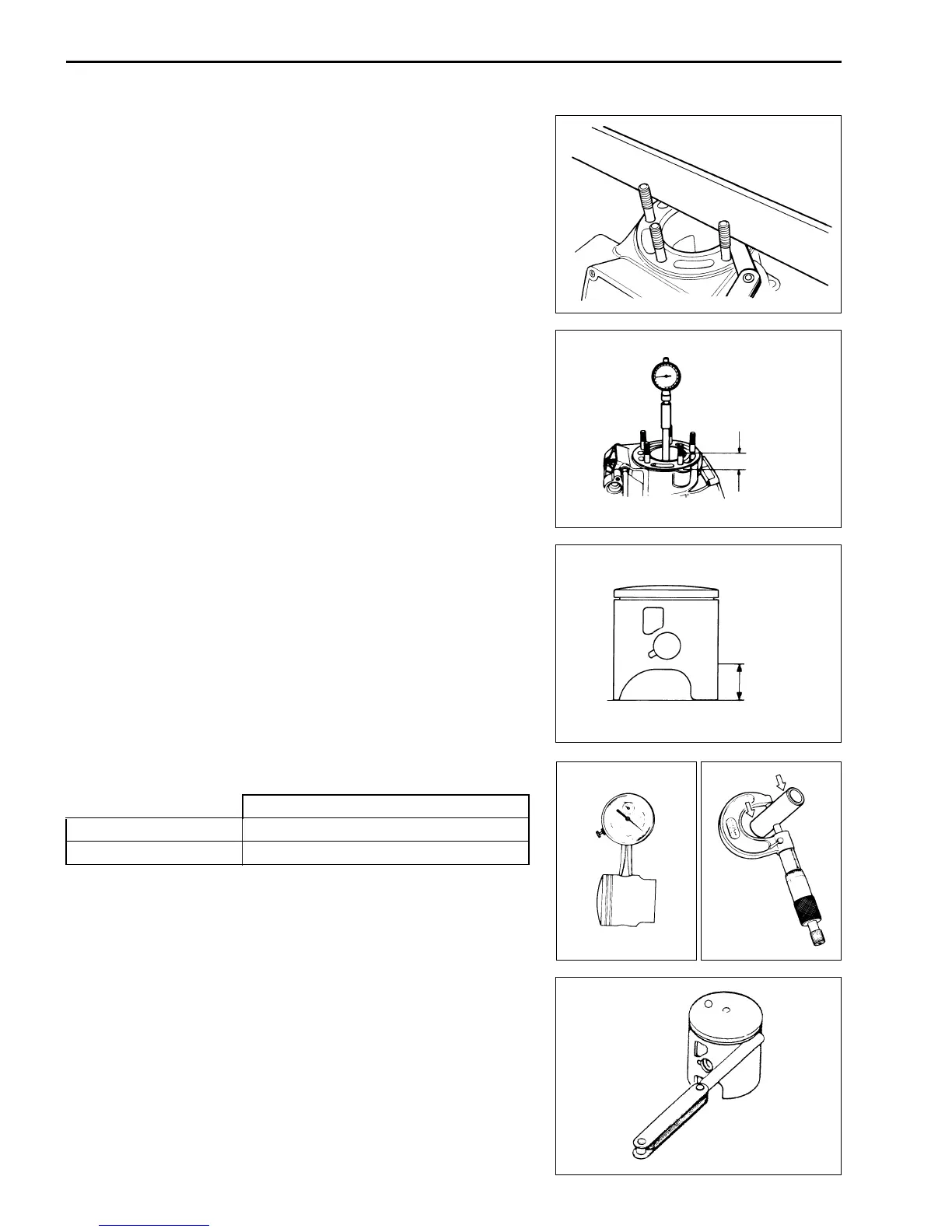

• Measure the cylinder bore for wear with a cylinder gauge 15

mm (0.59 in) from the top surface.

NOTE:

The cylinder bore must be measured perpendicular to the crank-

shaft axis direction.

Cylinder bore

Standard: 48.000 – 48.015 mm (1.8898 – 1.8904 in)

09900-20508: Cylinder gauge set (40 – 80 mm)

PISTON AND PISTON RING INSPECTION

• Remove the piston ring from the piston ring groove.

• Remove carbon deposits from the piston.

• Inspect the piston for wear, scratches and damage.

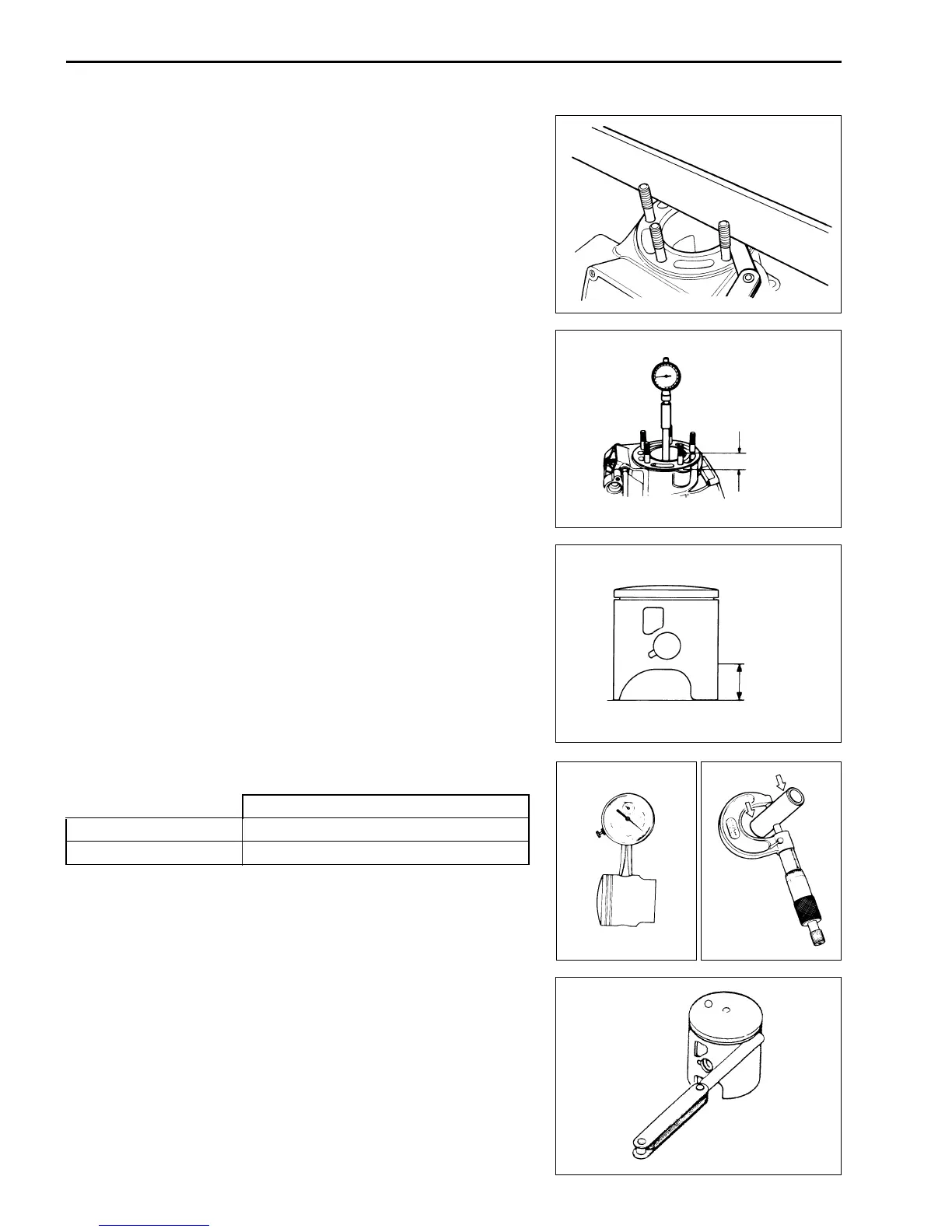

• Measure the piston outer diameter 16 mm (0.63 in) from the

skirt end.

Piston outer diameter

Service Limit: 47.880 mm (1.8850 in)

09900-20202: Micrometer (25 – 50 mm)

• Measure the piston pin bore and piston pin diameter.

09900-20605: Dial gauge

09900-20205: Micrometer (0 – 25 mm)

• Remove carbon deposits from piston ring and piston ring

groove.

• Fit the piston ring into the ring groove and measure the clear-

ance with a thickness gauge.

Piston ring to groove clearance

Standard: 0.020 – 0.060 mm (0.0008 – 0.0024 in)

09900-20803: Thickness gauge

15 mm

(0.59 in)

Service Limit

Piston pin bore 14.030 mm (0.5524 in)

Piston pin O.D. 13.980 mm (0.5504 in)

16 mm

(0.63 in)

Loading...

Loading...