Installation |

5

7 Installation

7.1 Safety information

Warning: Danger from falling fan or fan parts.

♦ Check the surface before installation for load bearing capacity.

♦ Consider all static and dynamic loads when selecting hoisting equipment and fastening components.

General safety information

♦ Installation may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 1.

♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment,

page 2.

♦ Abide by the system-related conditions and requirements of the system manufacturer or plant constructor.

♦ Do not dismantle or circumvent safety elements, or put them out of function.

♦ Move the impeller of the fan by hand before you install it in order to check that it moves freely.

♦ Provide contact and intake protection and ensure safety distances according to DIN EN ISO13857 and DIN 24167-1.

♦ Prevent the possibility of foreign bodies being drawn in.

♦ To reduce transmission of vibration to the duct system, we recommend flexible connections from our accessory

range, see chapter Accessories.

7.2 Preconditions

♦ Ensure that the fan and all its components are

undamaged.

♦ Ensure that there is enough space to install the fan.

♦ Protect against dust and moisture when installing.

♦ Ensure that the information on the name plates (fan

and motor) matches up with the operating conditions.

♦ Fit the fans in such a way that there is sufficient

access for troubleshooting, maintenance and repair.

Important

Damage to the bearings or other parts of the fan can occur.

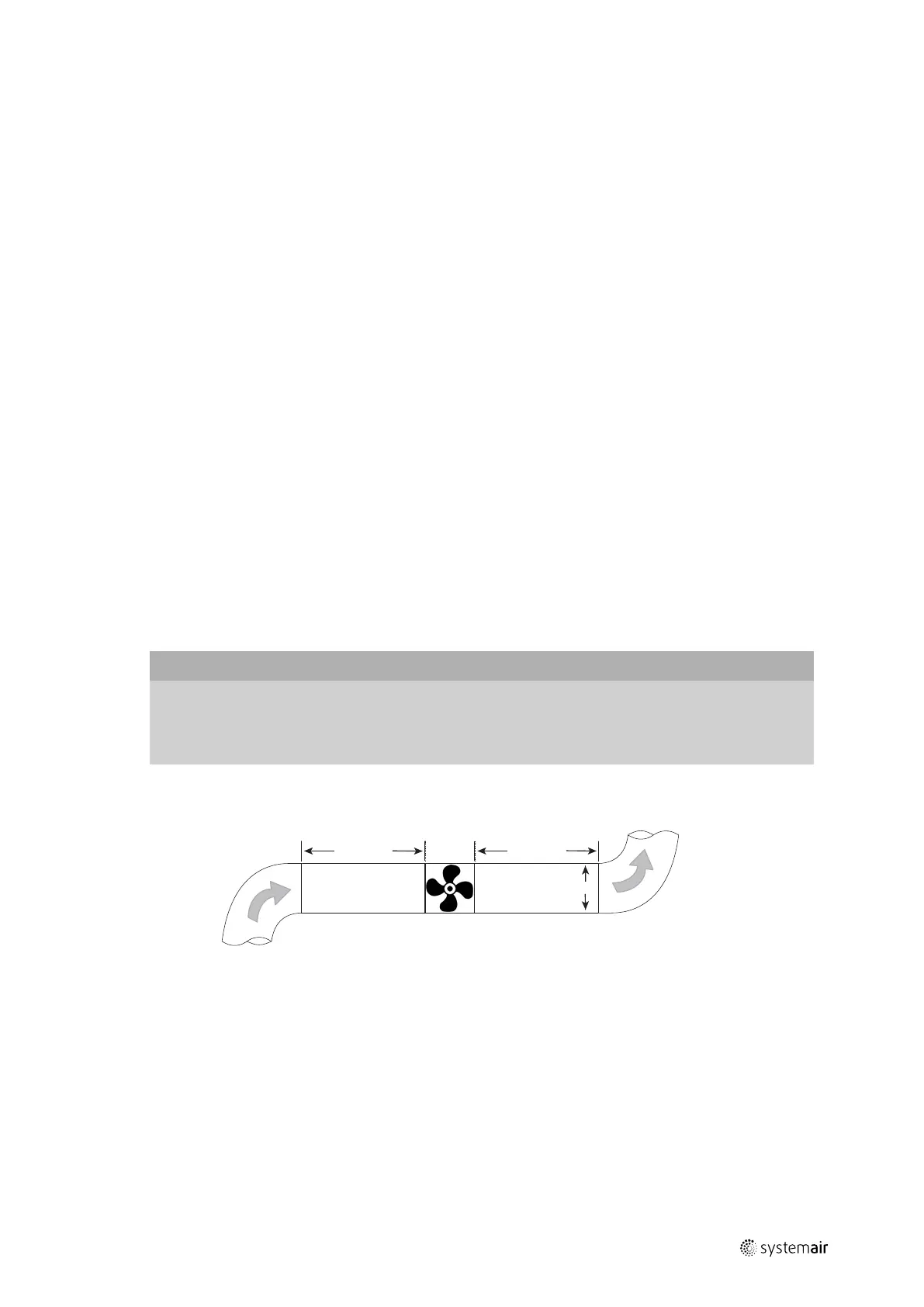

♦ Do not place a duct bend directly before or after the fan!

♦ Ensure a smooth and constant air flow to the device. Ensure a free exhaust. See Fig. 1 Straight ducts,

page 5.

• Rectangular duct system: D = Hydraulic diameter • Round duct system: D = Nominal diameter

Ø D

min.

2,5x Ø D

min.

2,5x Ø D

Fig. 1 Straight ducts

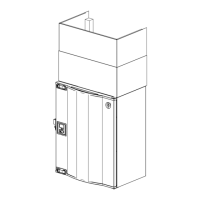

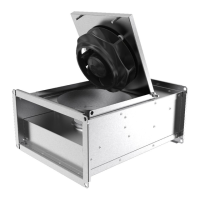

7.3 Installation variations

The installation is possible in any mounting position.

| 003

Loading...

Loading...