12_ TECHNICAL MENU

The control unit is supplied with standard factory settings, suitable

to move most doors commercially available, in compliance with

European standards.

However a series of parameters may be modied, by means of

dipswitches 7-8 and trimmers TRM4, TRM5 and TRM6.

The function of these trimmers varies according to the position of

dipswitches 7-8, as specied in the table below.

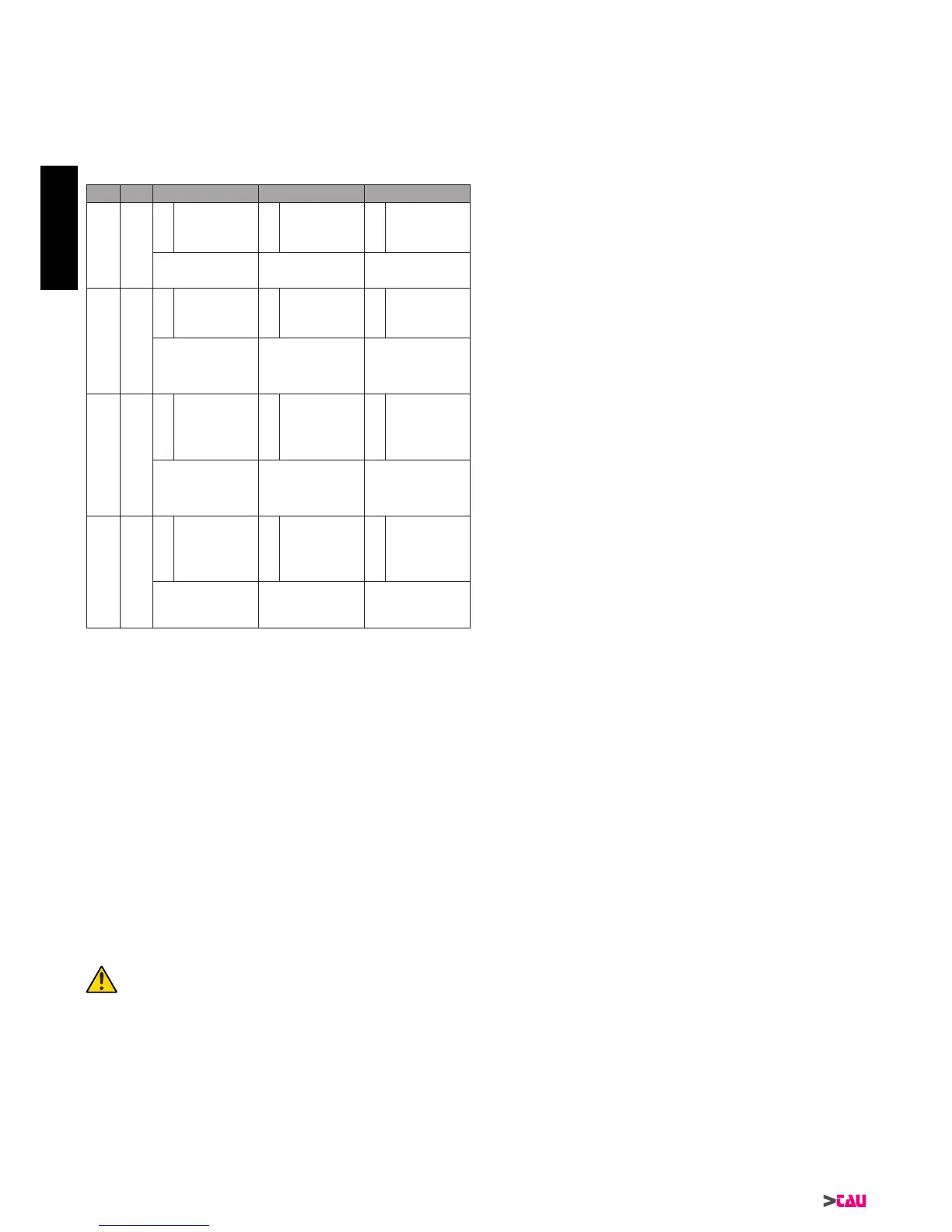

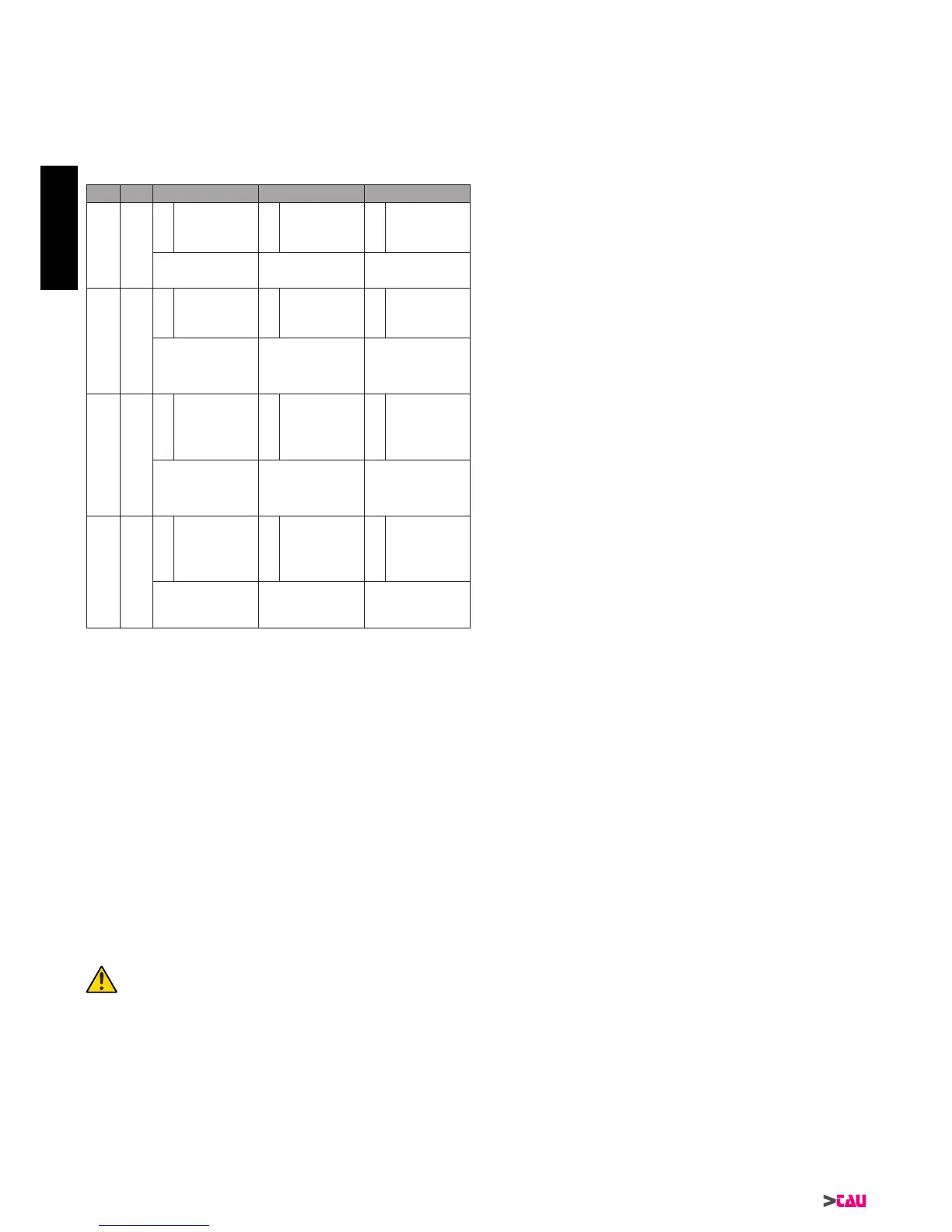

Dip7 Dip8 TRM4 TRM5 TRM6

OFF OFF

1

Set to decel-

eration on

opening

2

Set to de-

celerationon

closing

3

Minimum

speed(Vmin)

Turn clockwise for the

door to start deceleration

earlier

Turn clockwise for the

door to start deceleration

earlier

Turn clockwise for high

speed at the end of de-

celeration

OFF ON

4

Opening

speed (Vap)

5

Closing

speed (Vch)

6

Thrust on

closinglimit

position

Turn clockwise to in-

crease speed

Turn clockwise to in-

crease speed

At the end of closing the

motor pushes against the

limiter for a brief interval.

Turn clockwise to in-

crease time interval

ON OFF

7

Opening ac-

celeration

ramp

8

Closing ac-

celeration

ramp

9

Encoder

engagement

time (motor

start)

Turn clockwise to in-

crease time of accelera-

tion ramp

Turn clockwise to in-

crease time of accelera-

tion ramp

Turn clockwise to in-

crease the start-up time in

which the encoder signal

is ignored (no obstacles

are detected)

ON ON

10

Limit switch

position

onopening

(FCA)

11

Obstacle

detectionlimit

position on

closing

1

12

Belt loosen-

ing

Turn clockwise to in-

crease the stopping

distance from opening

limit switch

Turn clockwise to

increase the zone con-

sidered as closing limit

position.

Turn clockwise to in-

crease return to opening

at the end of closing, to

loosen the chain/belt.

Notes:

(

1

) if this parameter is modied, i.e. if the stopping distance

from the mechanical limiter is moved +/- forward, the value

”Opening limit position” (10) must be adjusted to guarantee

the space required to complete a complete manoeuvre.

Recommended procedure for adjustment:

1_ position dipswitches 7 and 8 on the combination re-

quired to modify the specic parameter;

2_ set ALL THREE trimmers to mid-way.

3_ press ENTER to conrm the parameters;

4_ perform a complete open/close manoeuvre and check

that the response is correct.

5_ adjust the trimmers;

6_ press ENTER;

7_ proceed as per point 4 to obtain the required response.

N.B. it is not possible to modify one parameter only. All

three parameters of the selected combination need to

be adjusted each time.

To restore the standard conguration to the control

unit (factory settings), press and hold ENTER for at le-

ast 5 sec.

13_ MALFUNCTIONS: TROUBLESHOOTING

The automation does not start

a_ Use a Multimeter to check presence of 230 Vac supply volt-

age.

b_ Check that the NC contacts of the card are effectively nor-

mally closed (3 green leds lit) and that the red leds for open-

ing commands are off.

c_ Set dipswitch 6 (fototest) to OFF;

d_ Set trimmers FRC and FRA to the maximum value;

e_ Use the Multimeter to check that the fuses are intact.

The radio control range is low

a_ Check that the earth connection and aerial signal have not

been inverted;

b_ Do not make joints to extend the aerial cable;

c_ Do not install the aerial at low heights or concealed by walls

or columns;

d_ Check status of the radio control batteries.

The door opens in the opposite direction

a_ Invert the motor connection (RED and BLACK wires on the

motor).

ENGLISH

Loading...

Loading...