14

8. Clean all metallic parts in carburetor cleaner. Do not

exceed 30 minutes soak time. Blow out all fuel

passages with compressed air. Do not use tag wire to

clean the orifice in the main mixture seat assembly.

The main mixture seat assembly contains a teflon disc

check valve. If the disc is damaged with tag wire, the

carburetor will not function properly.

CARBURETOR INSPECTION

Visually examine the throttle lever shaft and choke shaft

for wear at the bearing points in the carburetor body.

Inspect the pump and metering diaphragms for hardness,

fuel contamination, holes or tearing in the diaphragm.

Pump diaphragm flapper valves should appear flat with

no curling. Check the inlet screen and check valve screen

for contamination. Check the atmospheric vent hole in the

metering cover and clean if necessary.

Check the inlet needle for wear on the taper portion of the

needle. Replace as necessary.

CARBURETOR ASSEMBLY

1. Install new inlet screen(s) using a small flat punch

slightly smaller than the screen. Push in until the

screen contacts the seat.

2. If removed, install the high speed jet. Use a slightly

larger flat punch to install the brass welch plug over

the high speed jet. The closed, tapered end of the

plug goes toward the jet. Tap the brass welch plug in

until it is flush with the carburetor body. Apply sealant

like fingernail polish to the brass plug.

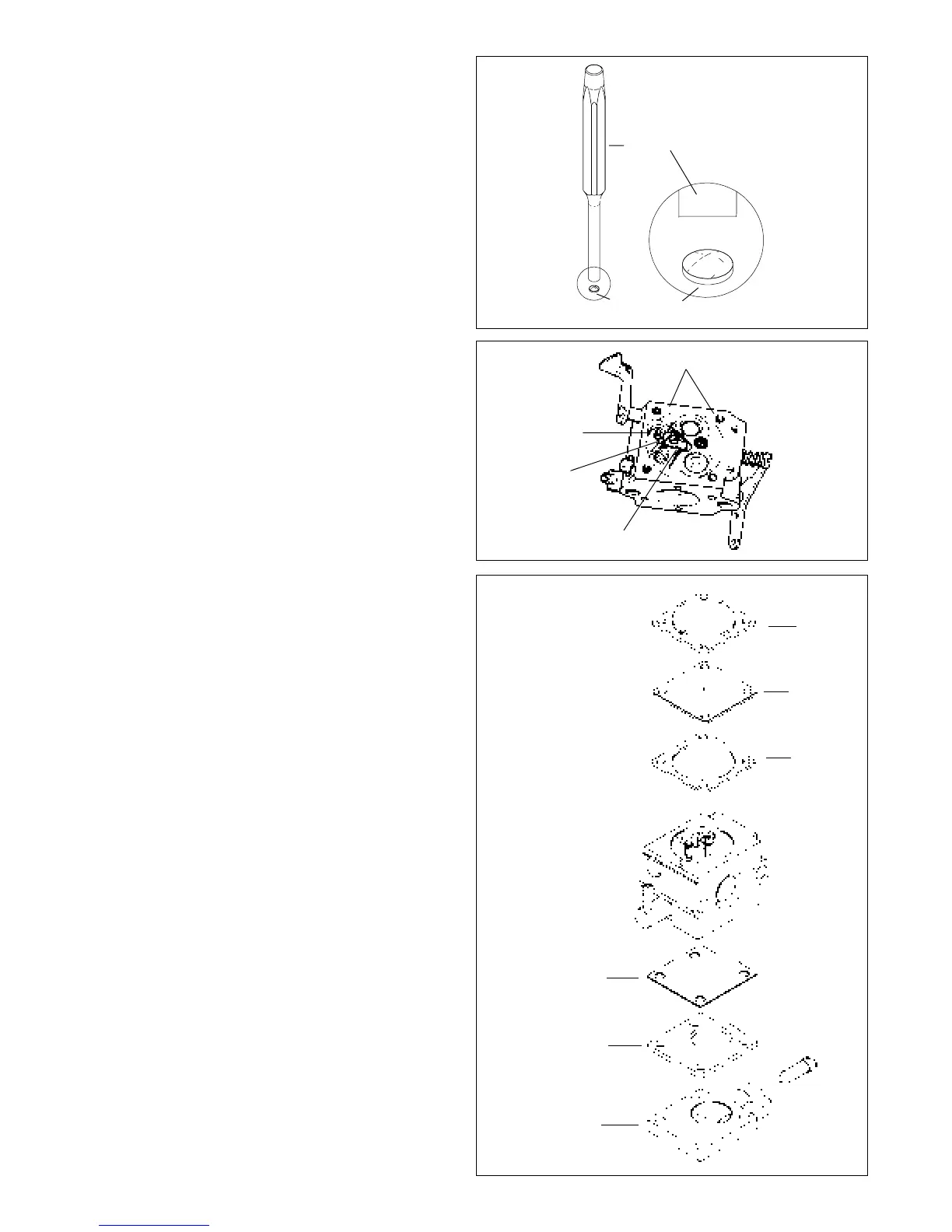

3. Install new welch plug(s) using a flat punch equal to

or slightly larger than the plug. The welch plug(s)

must be flattened by taps with a small hammer on

the installing punch. Sealant such as fingernail polish

is recommended to apply to an installed welch plug.

Use sparingly and wipe off excess immediately

(diag. 3-11).

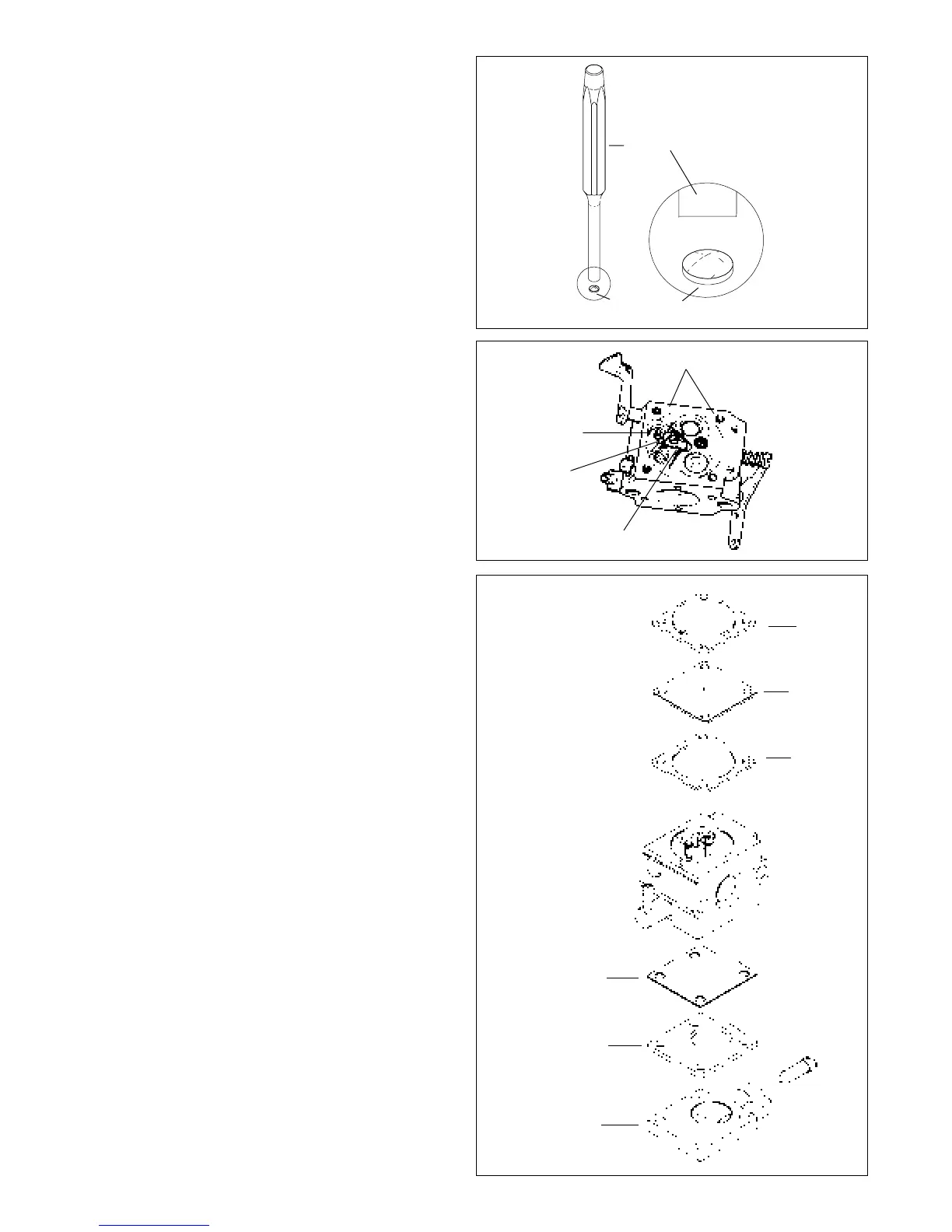

4. Install the inlet needle, spring, metering lever and

pin. The metering lever hooks on the inlet needle

and rests on the metering spring. Install as an

assembly and install the retaining screw

(diag. 3-12).

5. Check the metering lever tip height using a metering

lever gauge (part # 670325). The tip height should

be .060" to .070" (1.52 mm to 1.77 mm) from the

face of the carburetor body on Walbro carburetors.

On Tillotson carburetors the tip of the metering lever

should be flush with surface of the carburetor body.

6. Install the idle mixture screw and spring and back

the screw out from the closed position 1 - 1 1/8 turns

for Walbro, 1-1/4 - 1-3/8 turns for Tillotson

carburetors.

7. Install the metering diaphragm, cover gasket, and

cover. Place the cover gasket (over the locator pins

on Walbro only) on the carburetor body, add the

metering diaphragm with the long rivet head toward

the carburetor body on top of the gasket, add the

cover and fasten the four screws (diag. 3-13).

3-11

Flat End

Punch

New Welch

Plug

Note: Punch should be of the

same or larger diameter than

the welch plug.

3-12

3-13

1. Metering Diaphragm Cover

2. Diaphragm

3. Diaphragm Gasket

4. Pump Diaphragm

5. Pump Cover Gasket

6. Pump Cover

6

5

4

3

2

1

Metering Pin

Carburetor Face

Metering Lever Tip

Inlet Needle

Not For Resale

www.SmallEngineDiscount.com

Loading...

Loading...