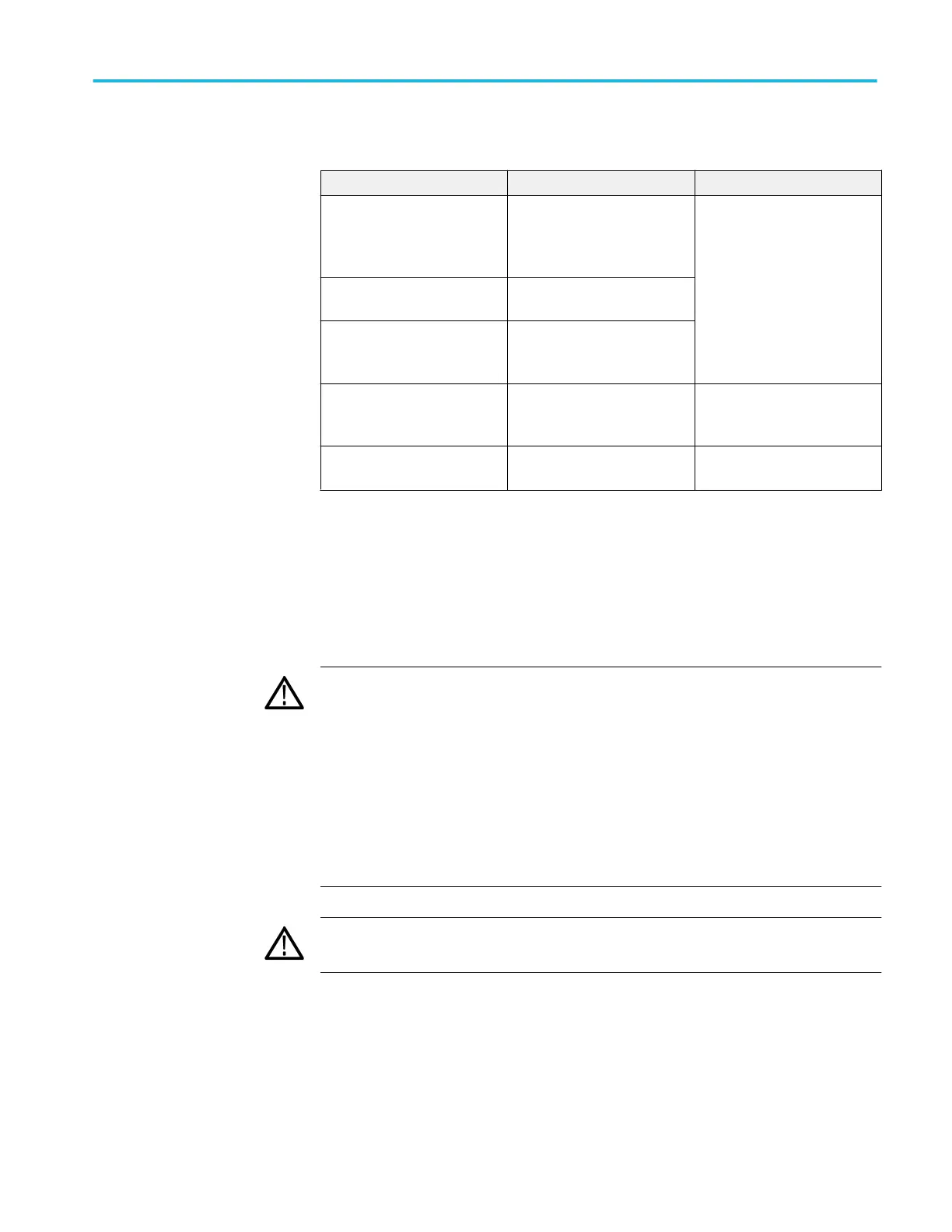

Table 2: Internal inspection checklist

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded

solder connections. Burned

circuit boards. Burned, broken,

or cracked circuit-run plating.

Remove and replace damaged

circuit board.

Resistors Burned, cracked, broken,

blistered condition.

Capacitors Damaged or leaking cases.

Corroded solder on leads or

terminals.

Wiring and cables Loose plugs or connectors.

Burned, broken, or frayed

wiring.

Firmly seat connectors.

Replace defective cables.

Chassis Dents, deformations, and

damaged hardware.

Straighten, repair, or replace

defective hardware.

Lubrication

There is no periodic lubrication required for this instrument.

Module removal

WARNING.

Only qualified personnel should perform service procedures. Before

performing this or any other procedure in this manual, read the General Safety

Summary and Service Safety Summary located at the beginning of this manual.

Also, to prevent possible injury to service personnel or damage to electrical

components, read Preventing ESD. (See Preventing ESD on page 9.)

To remove an assembly, refer to the exploded view diagrams and parts lists. (See

The replaceable parts list on page 23.)

If you are disassembling the instrument for cleaning, refer to the Inspection and

Cleaning procedure for instructions. (See Inspection and cleaning on page 10)

WARNING. Disconnect the power cord from the line voltage source. Failure to do

so could cause serious injury or death.

Maintenance

TBS2000B Series Service Manual 13

Loading...

Loading...