removedirt,butdonottwistit,asthefoam

maytear.

B.Drythefoamelementbywrappingitin

acleanrag.Squeezetheragandfoam

elementtodryit,butdonottwistit,asthe

foammaytear.

C.Saturatethefoamelementwithclean

engineoil.Squeezetheelementtoremove

excessoilandtodistributetheoil.

Note:Afoamelementthatisdampwith

oilisdesirable.

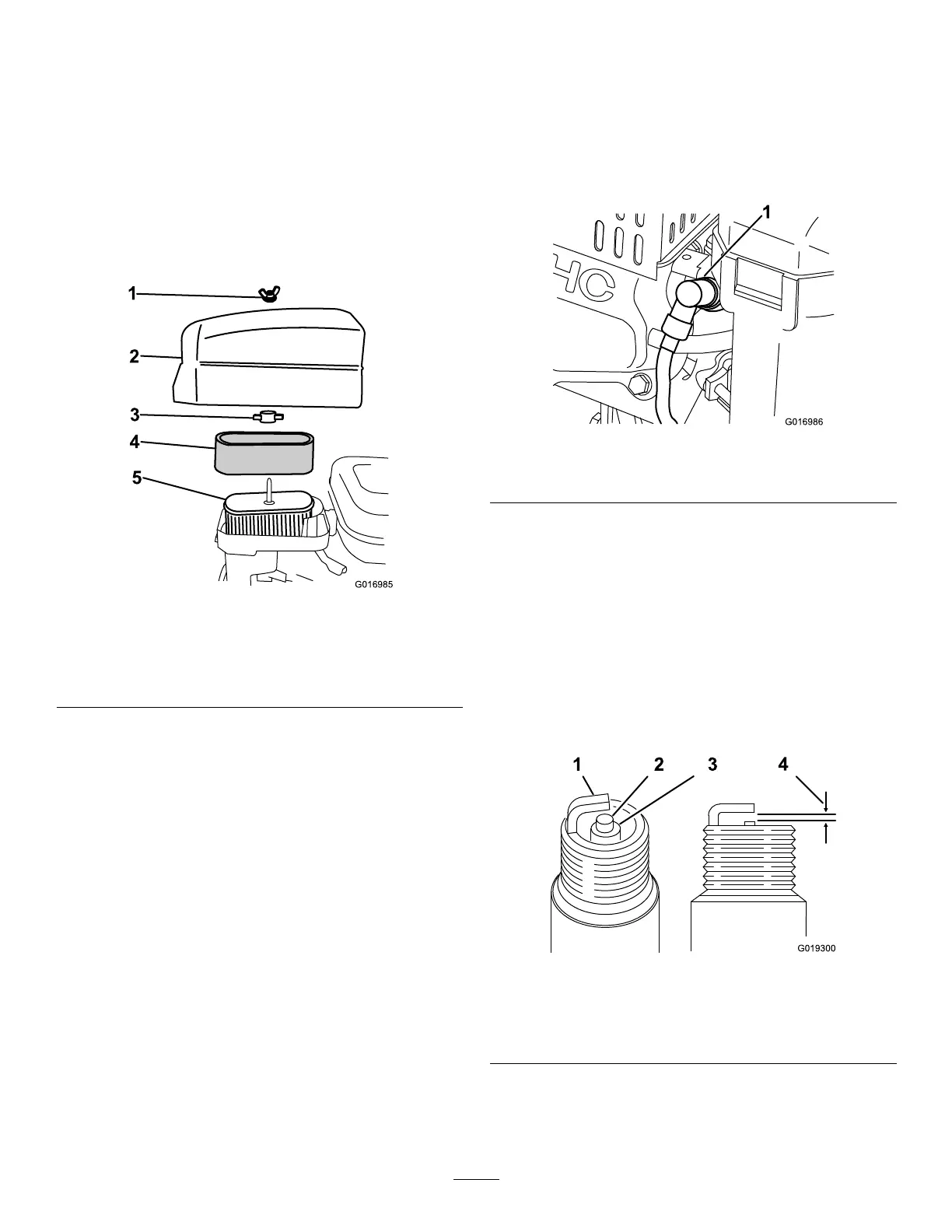

g016985

Figure32

1.Wingnut4.Foamelement

2.Air-cleanercover5.Paperelement

3.Plasticwingnut

5.Checktheconditionofthepaperelement.Clean

itbygentlytappingorreplaceitasnecessary.

Important:Donotusecompressedairto

cleanthepaperelement.

6.Installthefoamelement,paperelement,and

air-cleanercover.

Important:Donotoperatetheengine

withouttheair-cleanerelement,asextreme

enginewearanddamagecanresult.

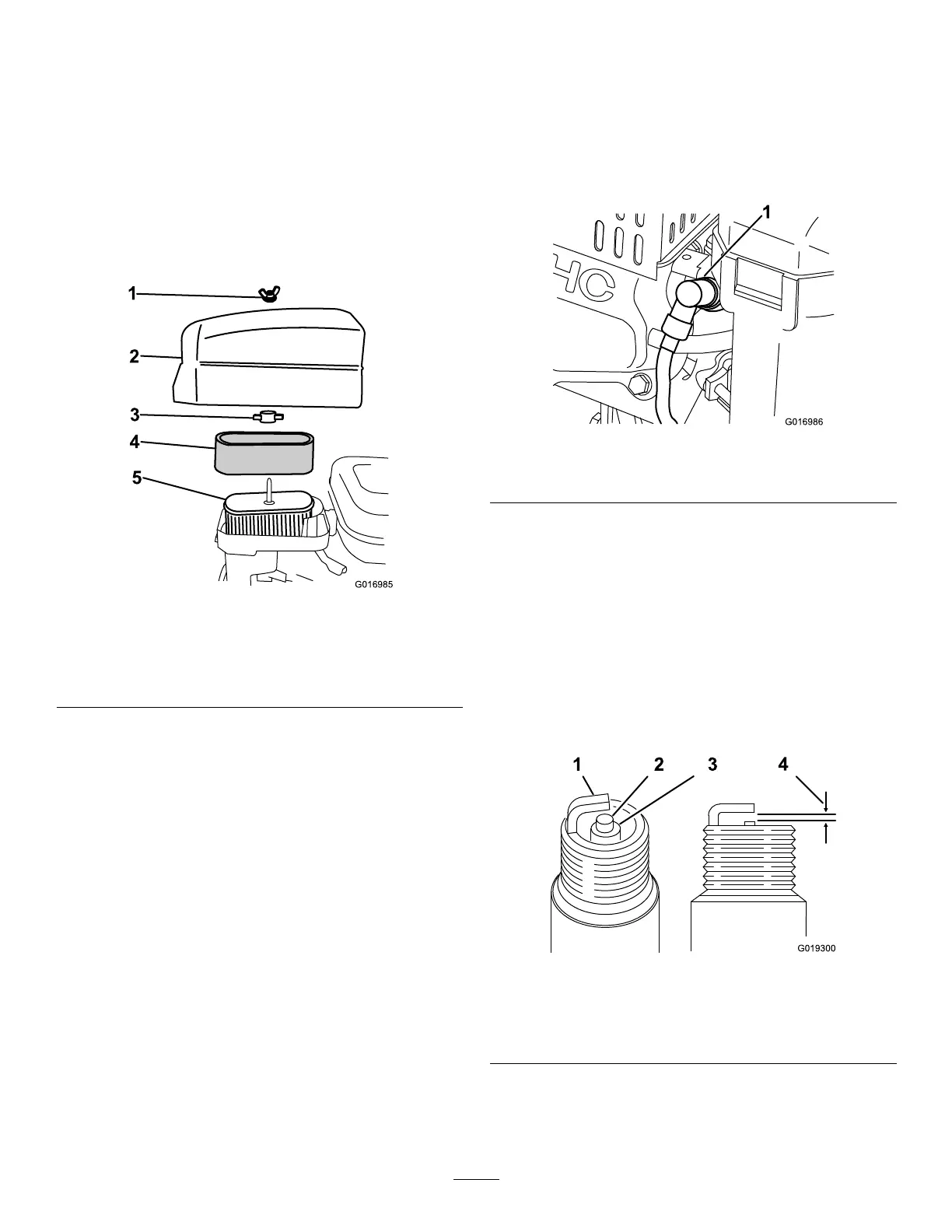

ServicingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBR6HSsparkplugorequivalent.The

correctairgapis0.6to0.7mm(0.024to0.028inch).

1.Pullthemoldedwireoffthesparkplug(Figure

33).

g016986

Figure33

1.Spark-plugwire

2.Cleanaroundthesparkplugandremovethe

plugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotsandblast,scrape,

orcleantheelectrodesbecauseengine

damagecouldresultfromgritenteringthe

cylinder.

3.Settheairgapat0.6to0.7mm(0.024to0.028

inch)asshowninFigure34.Installthecorrectly

gappedsparkplugandtightenitrmlyto23

N∙m(17ft-lb).

g019300

Figure34

1.Center-electrodeinsulator

3.Airgap—0.6to0.7mm

(0.024to0.028inch)

2.Sideelectrode

29

Loading...

Loading...