downsothatthebartsoverthebaracrossthetop

ofthecuttingunit(Figure12).

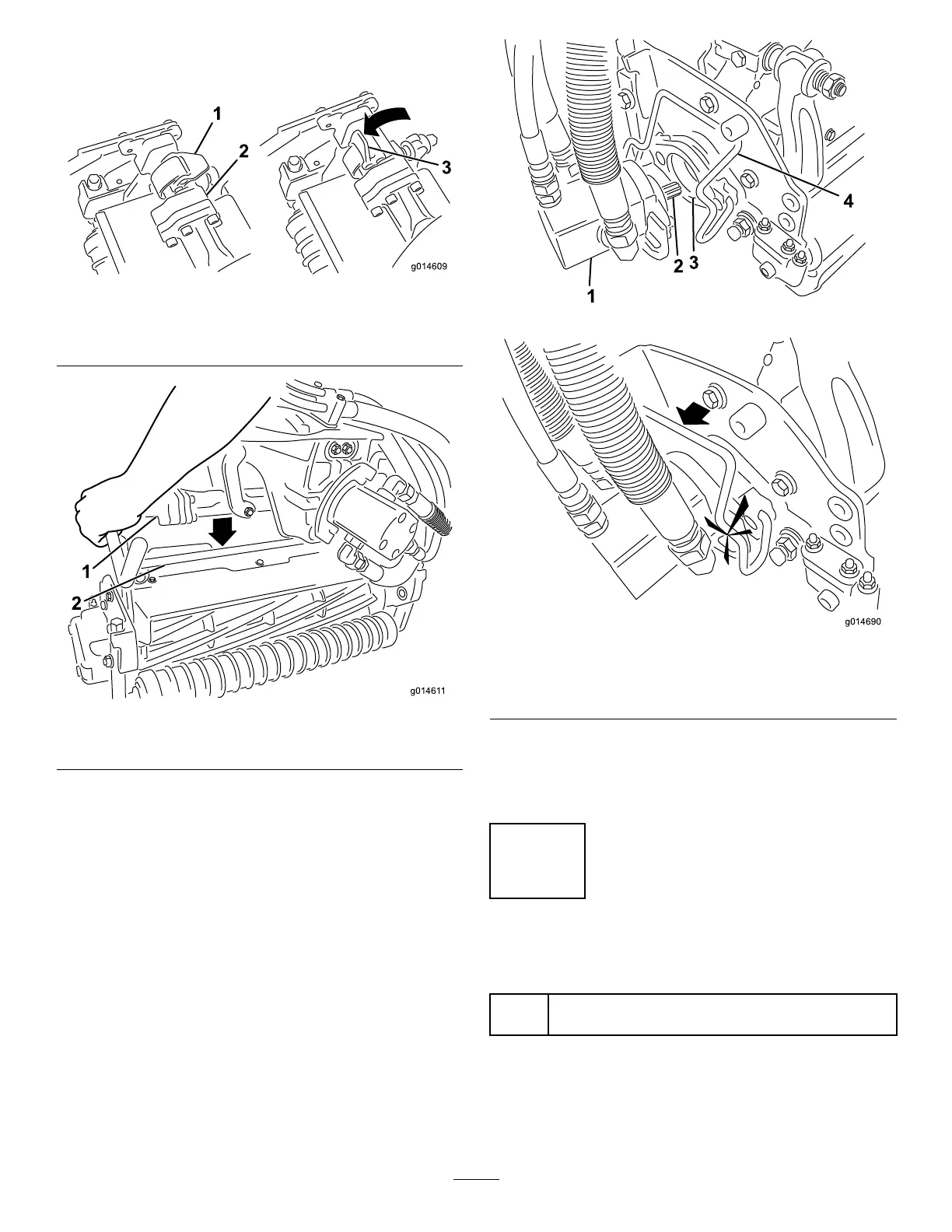

Figure11

1.Latch—closedposition3.Latch—openposition

2.Suspension-armbar

Figure12

1.Suspension-armbar2.Cutting-unitbar

6.Closethelatchesdownandaroundthecutting-unit

barandlocktheminplace(Figure11).

Note:A“click”canbeheardandfeltwhenthe

latchesareproperlylockedinplace.

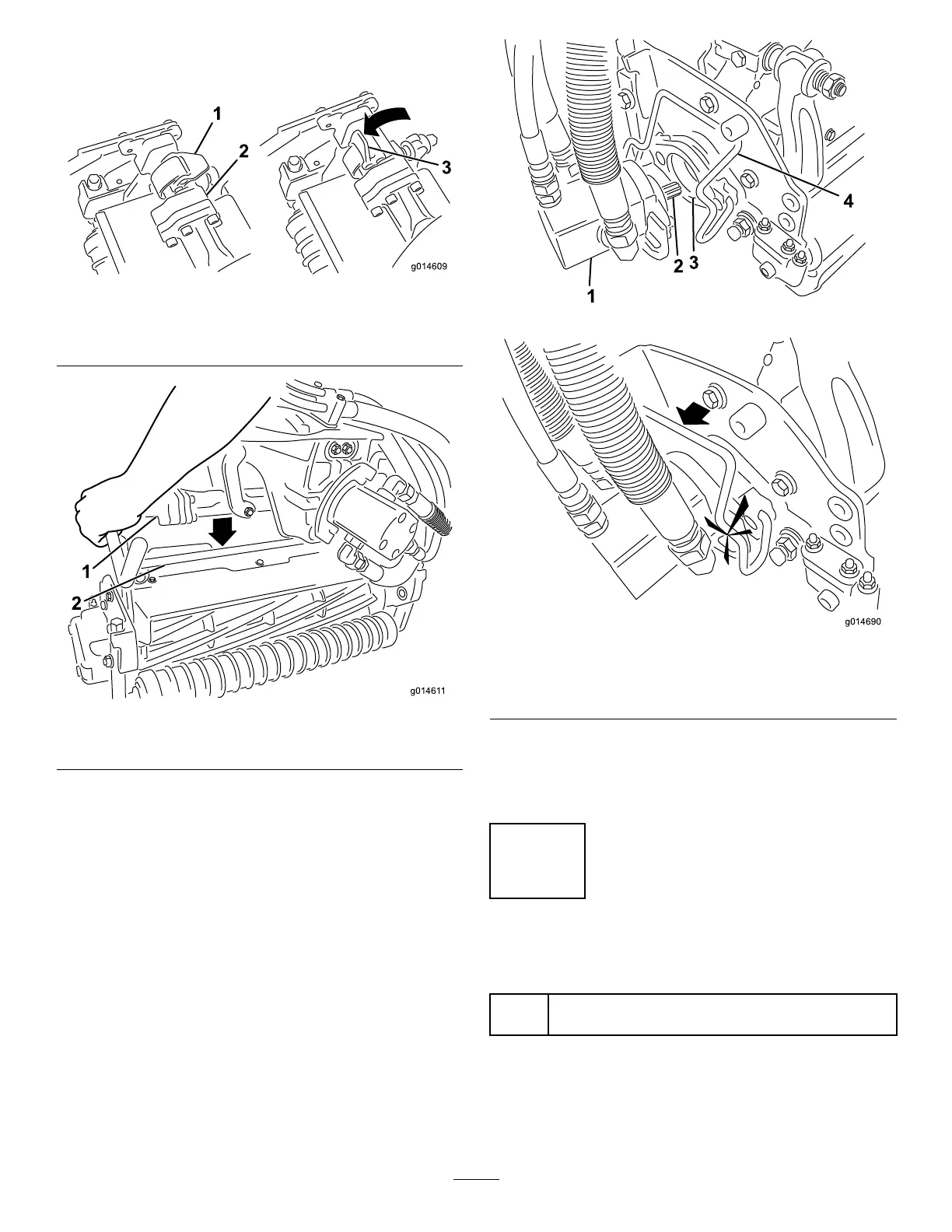

7.Coatthesplineshaftofthecuttingunitmotorwith

cleangrease(

Figure13).

8.Insertthemotorintotheleftsideofthecuttingunit

(asviewedfromtheoperator'sposition)andpullthe

motorretainingbaronthecuttingunittowardthe

motoruntilyouhearanaudible“click”fromboth

sidesofthemotor(

Figure13).

Figure13

1.Reelmotor

3.Cavity

2.Splineshaft

4.Motorretainingbar

9.Mountagrassbasketontothebaskethooksonthe

suspensionarm.

10.Repeatthisprocedurefortheothercuttingunits.

8

AddingRearWeight

Partsneededforthisprocedure:

1

Weightkit,121–6665(purchaseseparately)Note:not

requiredforunitswiththe3wheeldrivekitinstalled.

Procedure

ThisunitcomplieswiththeANSIB71.4-2004andEN

836Standardswhenequippedwithweightkit119-7129.

18

Loading...

Loading...