2.Toadjustrearrollerproceedasfollows:

•Raisetherearofthecuttingunitandplacea

blockunderthebedknife.

•Removethe(2)nutssecuringeachrollerbracket

andspacertoeachsideplatemountingange.

•Lowertherollerandscrewsfromthesideplate

mountingangesandspacers.

•Placethespacersontothescrewsontheroller

brackets.

•Re-securetherollerbracketandspacerstothe

undersideofthemountingangeswiththenuts

previouslyremoved.

3.Verifythatthebedknifetoreelcontactiscorrect.

Tipthemowertoexposethefrontandrearrollers

andthebedknife.

Note:Thepositionoftherearrollertothe

reeliscontrolledbythemachiningtolerances

oftheassembledcomponentsandparallelingis

notrequired.Alimitedamountofadjustmentis

possiblebysettingthecuttingunitonasurfaceplate

andlooseningthesideplatemountingcapscrews

(

Figure14).Adjustandre-tightencapscrews.

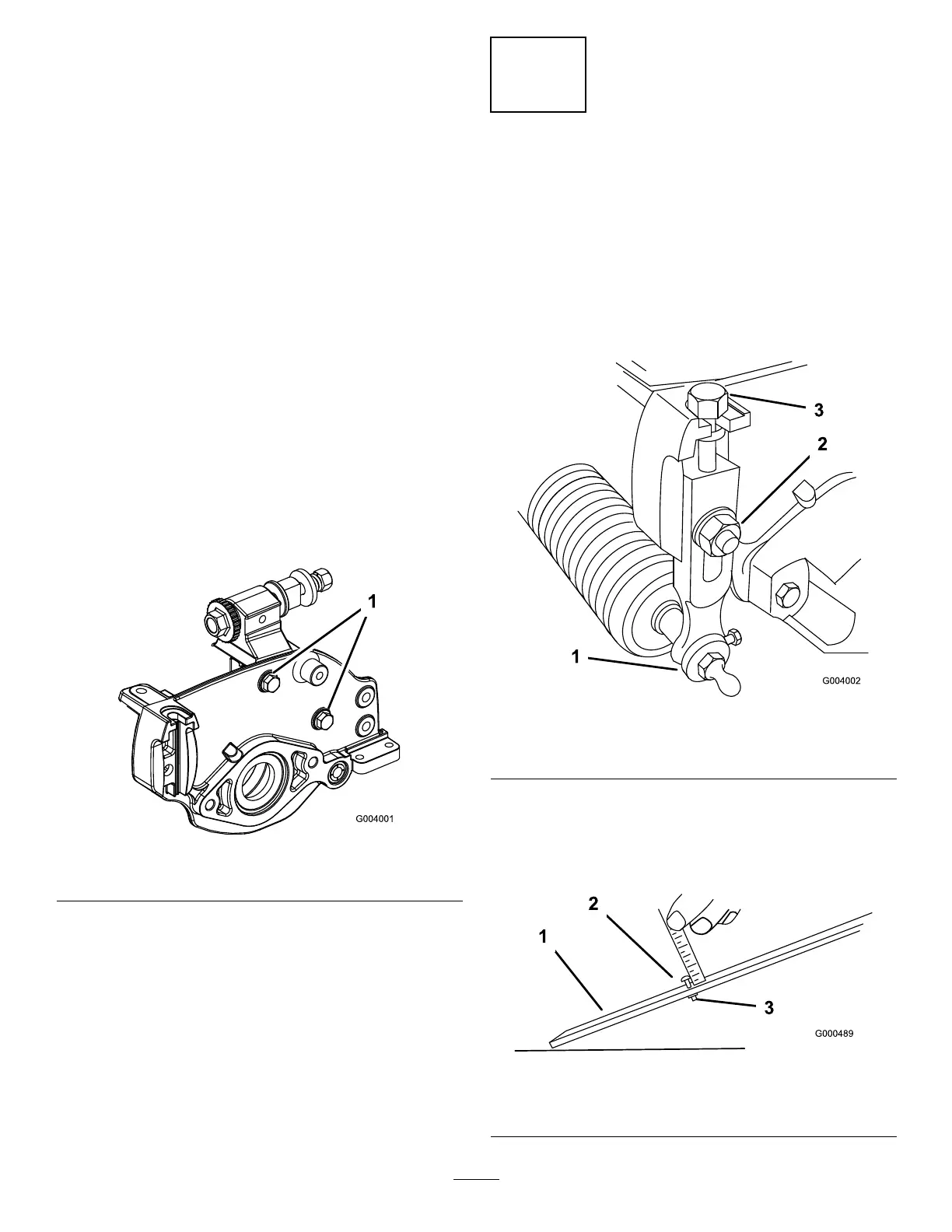

Figure14

1.Sideplatemountingcapscrews

Important:Wheneverthecuttingunithastobe

tippedtoexposethebedknife/reel,propupthe

rearofthecuttingunittomakesurethenutson

thebackendofthebedbaradjustingscrewsare

notrestingontheworksurface(Figure6).

7

AdjustingtheHeightofCut

NoPartsRequired

Procedure

Note:Forheightsofcutgreaterthan.500inch,the

highheightofcutkitmustbeinstalled.

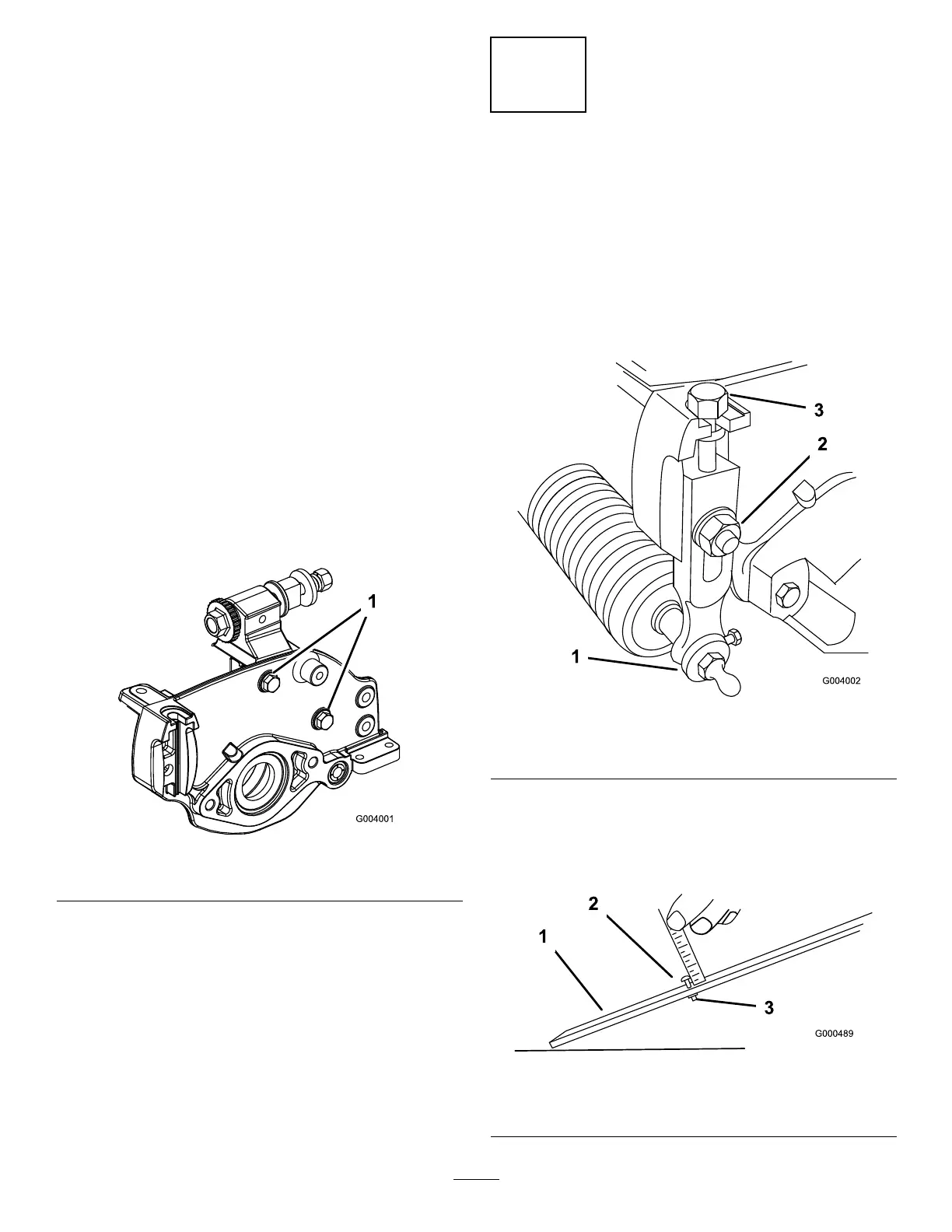

1.Loosenthelocknutssecuringtheheight-of-cutarms

tothecuttingunitsideplates(Figure15).

Figure15

1.Height-of-cutarm

3.Adjustingscrew

2.Locknut

2.Loosenthenutonthegaugebarandsettheadjusting

screwtothedesiredheight-of-cut(Figure16).The

distancebetweenthebottomofthescrewheadand

thefaceofbaristheheight-of-cut.

Figure16

1.Gaugebar

3.Nut

2.Heightadjustingscrew

8

Loading...

Loading...