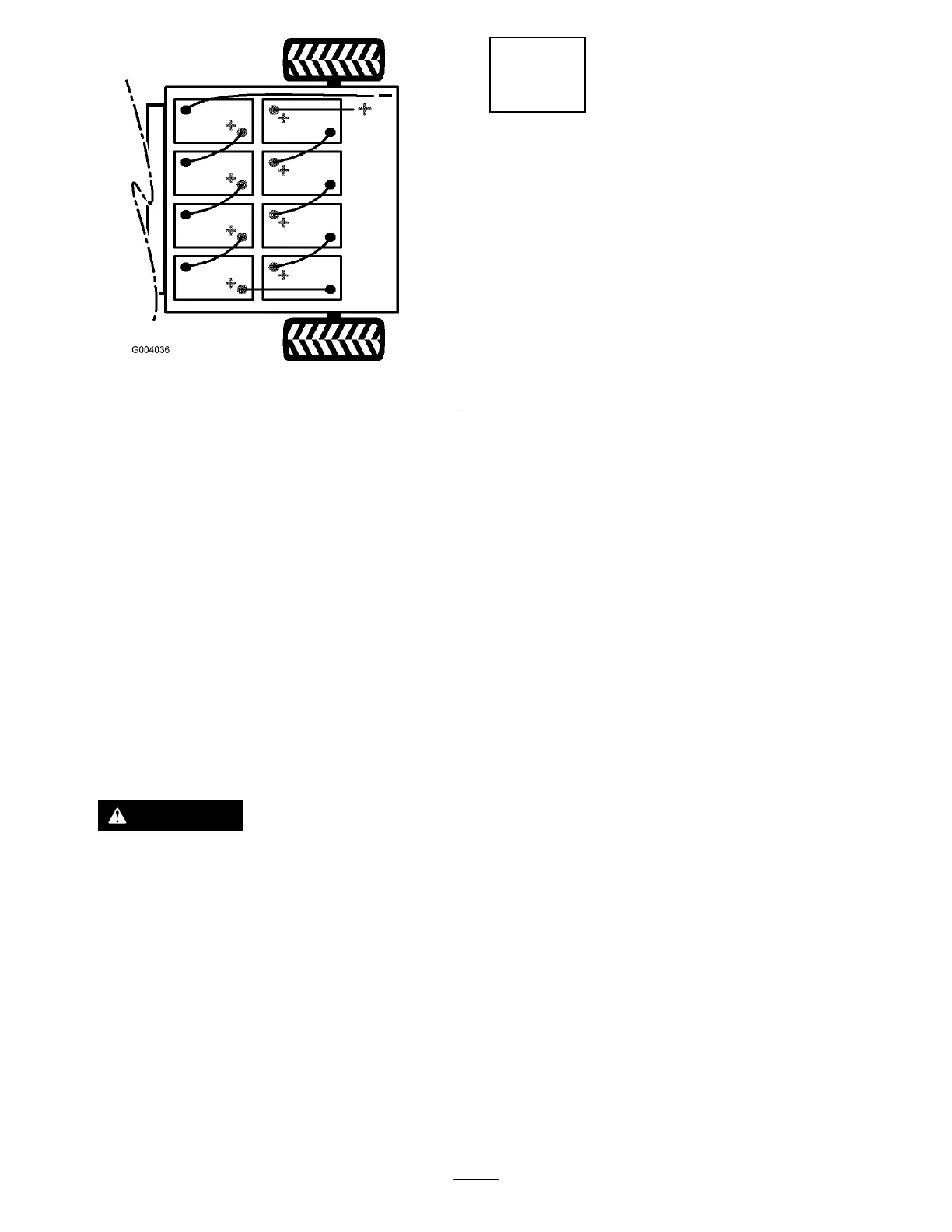

Figure6

5.Installthebatteryretainersandtorquethenutsto17to

22N-m(150to200in-lbs).

6.Connectthebatteriestogetherwiththebatterycables

includedinlooseparts(Figure6).

Important:Checkallhigh-currentbattery

connectionstoensurethattheyhavebeenproperly

secured.

Note:Ensurethatthecableroutingdoesnotallow

cablestocontactanysharpedges.

7.Tightentheboltandsecuretheothersideoftheclip

withanewbolt(5/16x3/4inch)andaangenut

(5/16inch)(Figure6).

8.Connectthelong,red,mainpositiveleadbetweenthe

bankofbatteriesandthemachine(Figure6).

9.Connectthelong,black,mainnegativeleadbetween

thebankofbatteriesandthemachine(Figure6).

WARNING

Looseorimproperlysecuredbattery

connectionscoulddamagethemachineand

cables,causingsparks.Sparkscancause

thebatterygassestoexplode,resultingin

personalinjury.

Alwaysensurethebatterypolaritywhen

makingconnections.

10.Torquethenutssecuringallbatterycablesto13.5to21

N-m(120to180in-lbs).

11.CoatthebatteryterminalswithTorobattery-terminal

protector.

12.Ensurethattherubbercoversoneachbatterycableare

securelyseatedoverthebatteryterminals.

3

CheckingtheTirePressure

NoPartsRequired

Procedure

Checkthetirepressureevery8hoursordailytoensure

properlevels.

Theairpressurerangeinthefrontandreartiresis55to152

kPa(8to22psi).

Theairpressureneededisdeterminedbythepayloadcarried.

Lowerairpressurewillprovidelesscompaction,asmoother

ride,andfewertiremarks.Lowerpressureshouldnotbeused

forheavypayloadsathighspeeds.

Higherpressuresshouldbeusedforheavierpayloadsandat

higherspeeds.Donotexceedthemaximumpressure.

13

Loading...

Loading...