DriveSystem

Maintenance

AdjustingtheSelf-propelDrive

ServiceInterval:Every100hours

Ifthelawnmowerdoesnotself-propelorhasatendency

tocreepforwardwhenthecontrolbarismorethan

1-1/2inches(3.8cm)fromthehandle,adjustthewheel

drivecontrolknobontherearofthegearbox.

1.Closethedoorinthelawnmowerhousingand

removethegrassbag.

2.Rotatethecontrolknobclockwiseahalfturnif

thelawnmowerdoesnotself-propel.Ifthelawn

mowercreepsforward,rotatetheknobahalfturn

counterclockwisetoloosenthebelt(

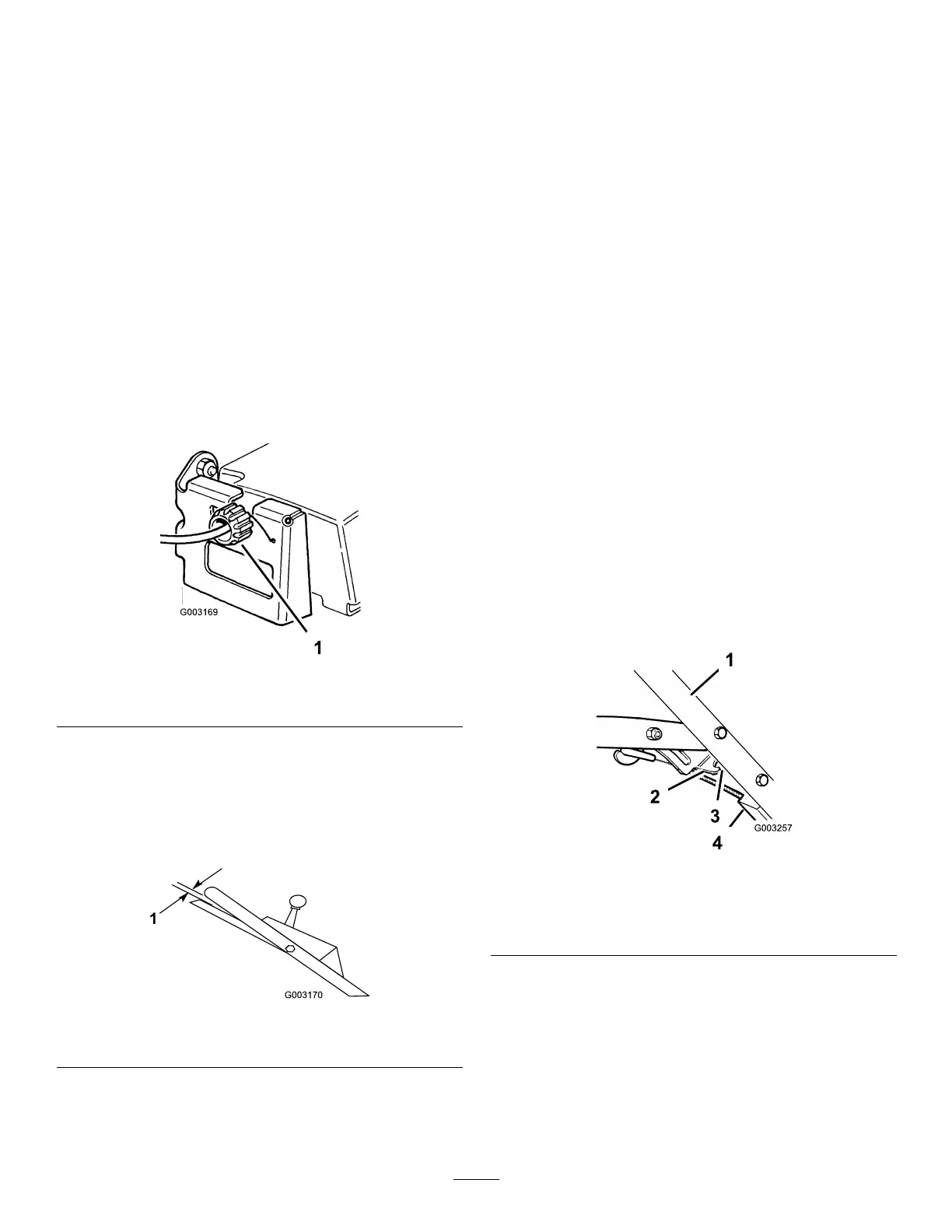

Figure25).

Figure25

1.Controlknob

3.Slowlypullthelawnmowerbackwardwhileyou

graduallymovethecontrolbartowardthehandle.

Note:Theadjustmentiscorrectwhentherear

wheelsstopturningandthecontrolbarisaboutone

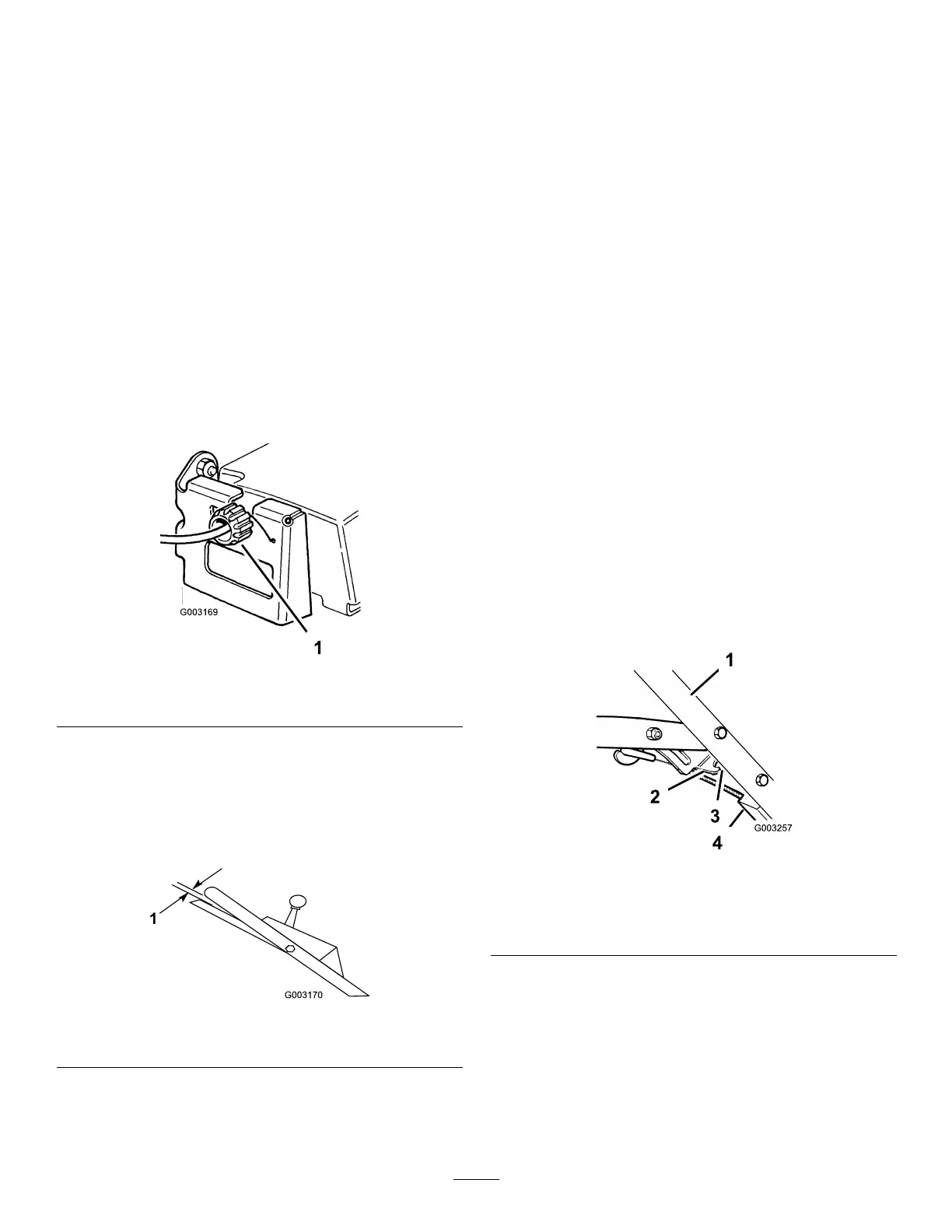

inch(2.5cm)fromthehandle(Figure26).

Figure26

1.1inch(2.5cm)

ControlsSystem

Maintenance

AdjustingtheBladeBrake

Cable

ServiceInterval:Beforeeachuseordaily—Ensurethat

theenginestopswithin3seconds

afterreleasingthebladecontrolbar.

Every100hours—Adjusttheblade

brakecable.

Wheneveryouinstallanewbladebrakecableassembly,

adjustit.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Checktheadjustmentofthecablebymovingthe

bladecontrolbartowardthehandleuntilyouremove

theslackinthecable.

Note:Thegapbetweenthebrakeleverandthe

handlemustbebetween3/16and1/4inch(5and6

mm).toadjustthecable.

4.Toadjustthecable,dothefollowing:

A.Loosenthenutonthecablebracket(

Figure27).

Figure27

1.Handle

3.3/16to1/4inch(5to6

mm)

2.Brakelever

4.Cablebracket

B.Inserta3/16to1/4inch(5to6mm)object

betweenthebrakeleverandthehandle

(Figure15).

C.Pulldownonthecableconduituntilyouremove

theslackfromthewire(Figure15).

D.Tightenthenut(Figure15).

21

Loading...

Loading...