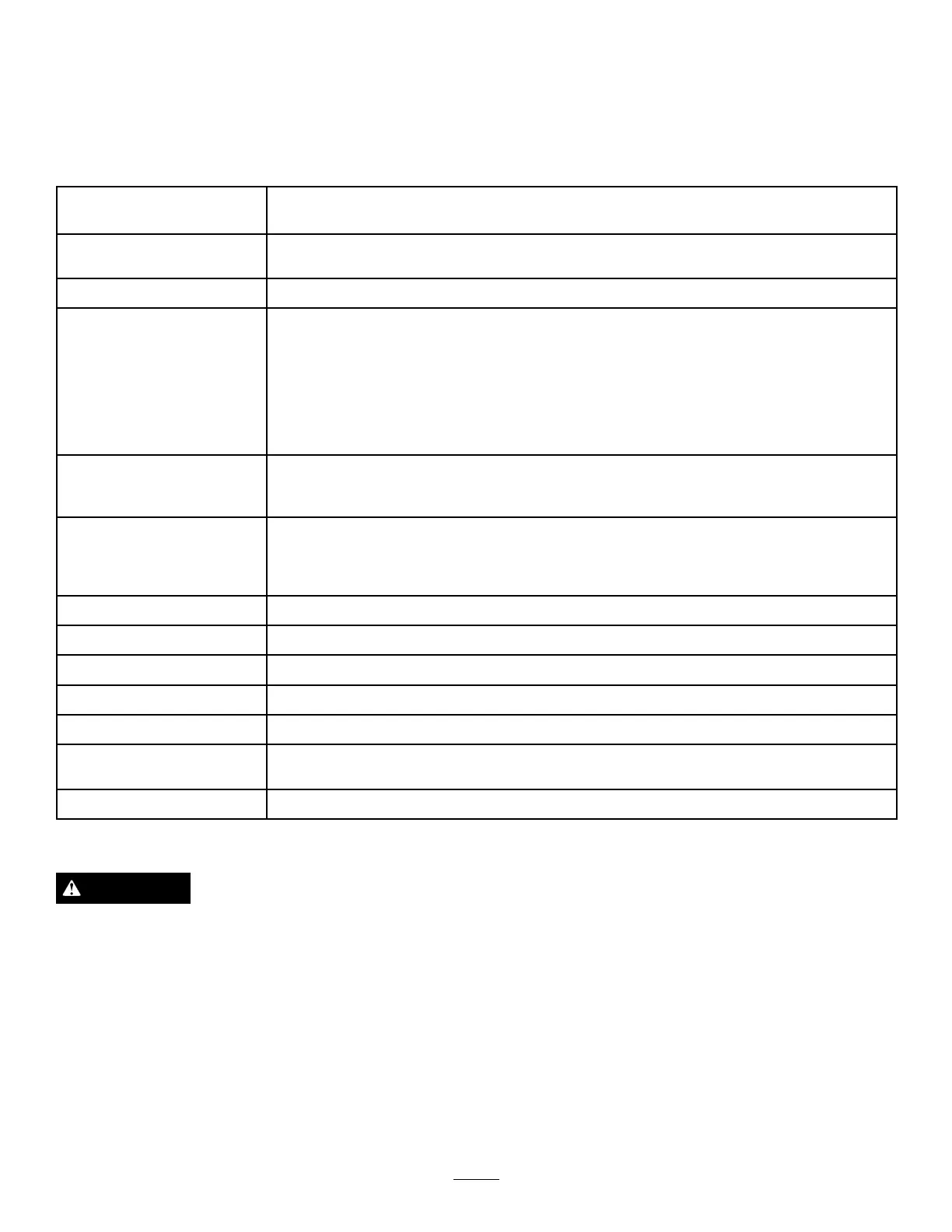

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Replacethehydrauliclter.

•T orquethewheellugnutsto50ft-lb(68N⋅m).

Aftertherst50hours

•Changetheengineoilandlter.

Beforeeachuseordaily

•Drainwaterfromthefuellter.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Removedebrisfromthetractionunit.

•T esttheparkingbrake

•Checkthetirepressure.

•Greasethetractionunit.

•Checkforloosefasteners.

Every25hours

•Checkthehydraulicuidlevel.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

Every75hours

•Changetheengineoilandlter(morefrequentlywhenoperatingconditionsare

extremelydustyorsandy).

•Checkthebatteryelectrolytelevel.(Replacementbatteryonly)

•Checkthebatterycableconnections.

Every100hours

•T orquethewheellugnutsto50ft-lb(68N⋅m).

Every200hours

•Replacetheprimaryairlter.

Every400hours

•Replacethehydrauliclter.

Every600hours

•Replacethesafetyairlter.

Every1,500hours

•Replaceallmovinghydraulichoses.

Yearly

•Changethefuellter.

•Changethehydraulicuid.

Yearlyorbeforestorage

•T ouchupchippedpaint

Important:Refertoyour

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

26

Loading...

Loading...