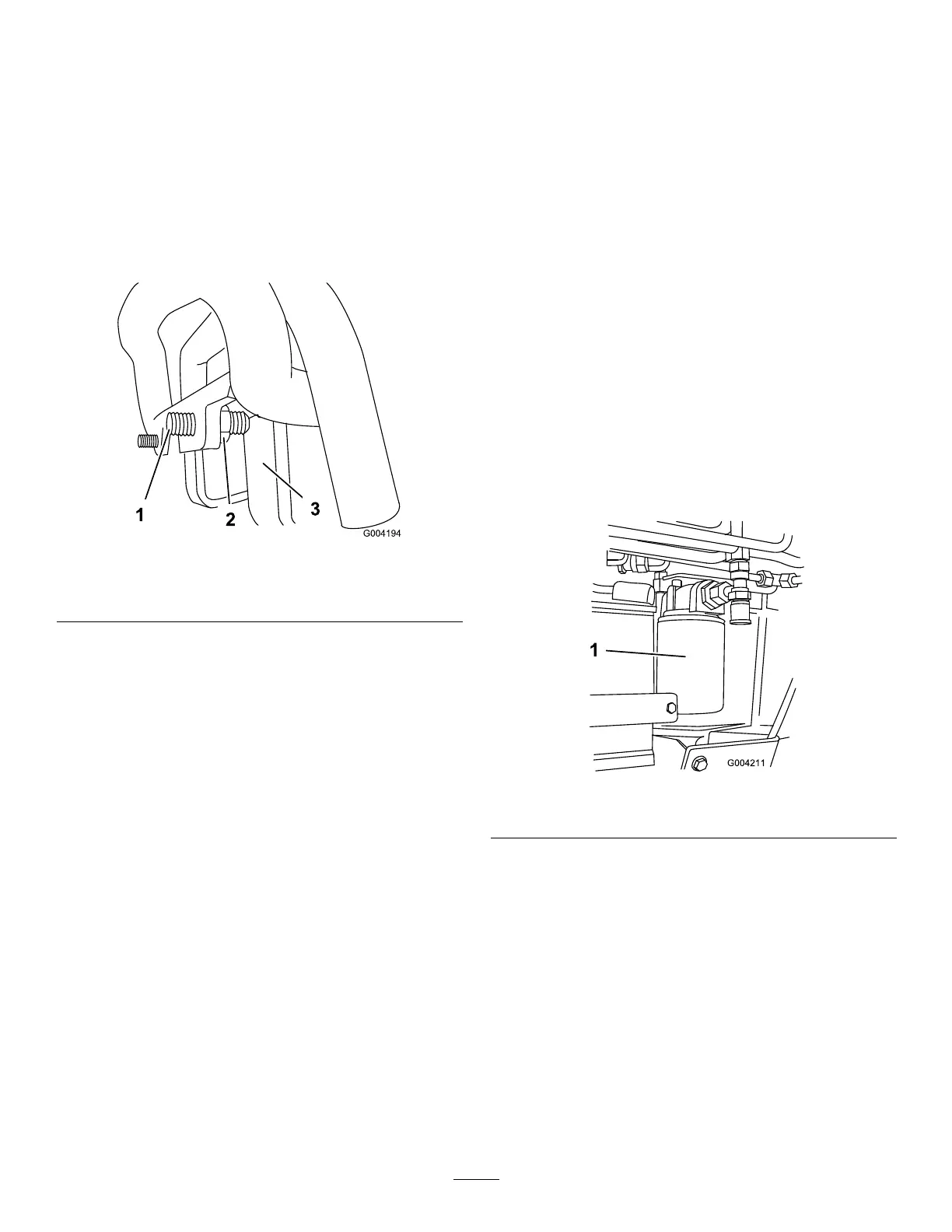

1.Drivethetractionunitwiththetractioncontrol

againstthereferencebar,notingwhichdirectionthe

tractionunitveers.

2.Releasethetractioncontrol.

3.Ifthetractionunitveerstotheleft,loosentheright

jamnutandadjustthetrackingsetscrewonthefront

ofthetractioncontrol(Figure53).

4.Ifthetractionunitveerstotheright,loosenthe

leftjamnutandadjustthetrackingsetscrewonthe

frontofthetractioncontrol(Figure53).

Figure53

1.Setscrew3.Stop

2.Jamnut

5.Repeatsteps1through4untilthetractionunitdrives

straightinthefullforwardposition.

Important:Ensurethetrackingsetscrews

touchthestopsinthefullforwardpositionto

avoidoverstrokingthehydraulicpumps.

HydraulicSystem

Maintenance

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst8hours

Every200hours

Important:Donotsubstituteanautomotiveoil

lterorseverehydraulicsystemdamagemayresult.

Changethehydrauliclter:

•Aftertherst8operatinghours

•Afterevery200operatinghours

1.Positiontractionunitonalevelsurface.

2.Lowertheloaderarms,stoptheengine,andremove

thekey.

3.Opentherearaccesscover.

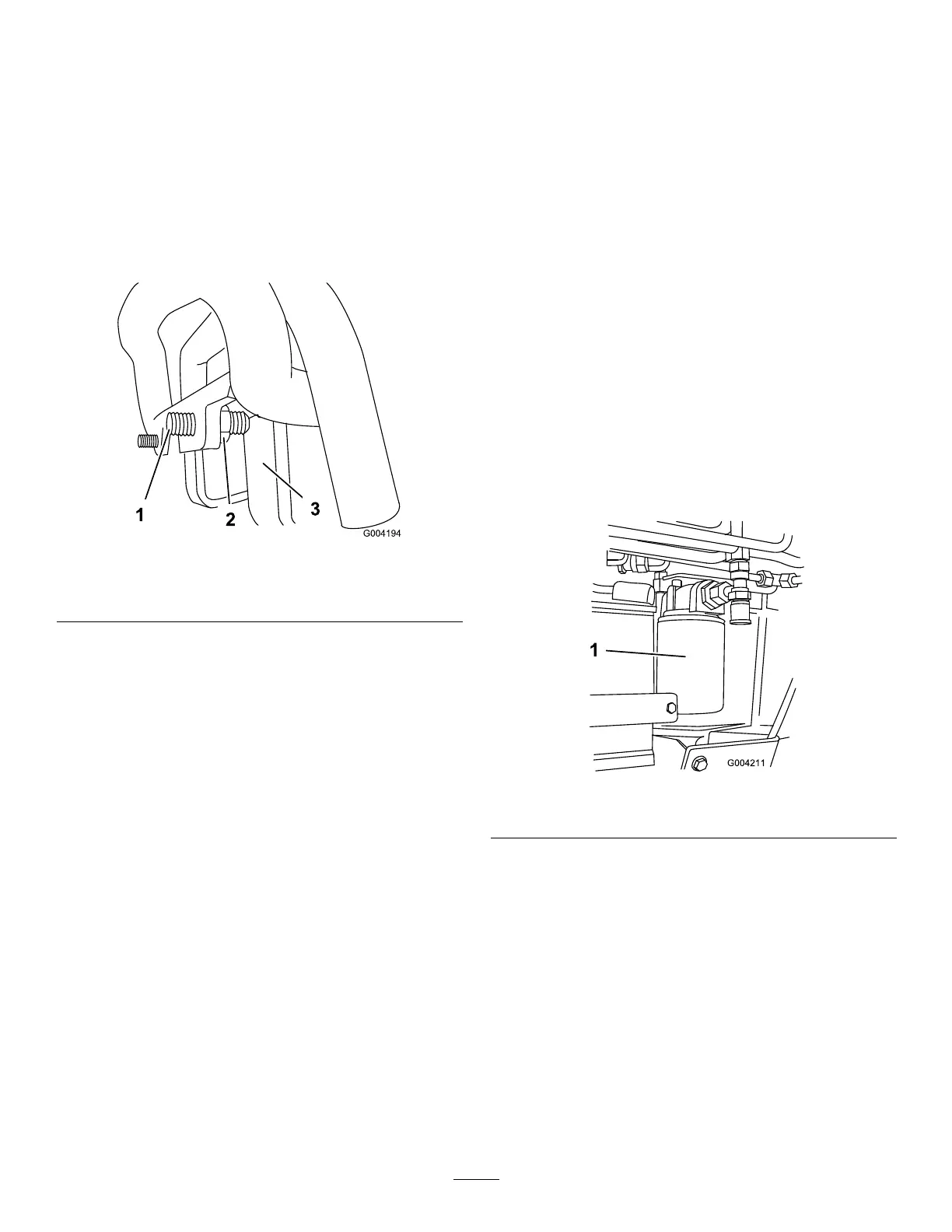

4.Placeadrainpanunderthelter(Figure54).

Figure54

1.Hydrauliclter

5.Removetheoldlter(Figure54)andwipethe

surfaceofthelteradaptergasketclean.

6.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter.

7.Installthereplacementhydrauliclterontothelter

adapter(Figure54).Tightenitclockwiseuntilthe

rubbergasketcontactsthelteradapter,thentighten

thelteranadditional3/4turn.

8.Cleanupanyspilleduid.

9.Starttheengineandletitrunforabouttwominutes

topurgeairfromthesystem.

10.Stoptheengineandcheckforleaks.

38

Loading...

Loading...