%#/,!

$/( -,!1

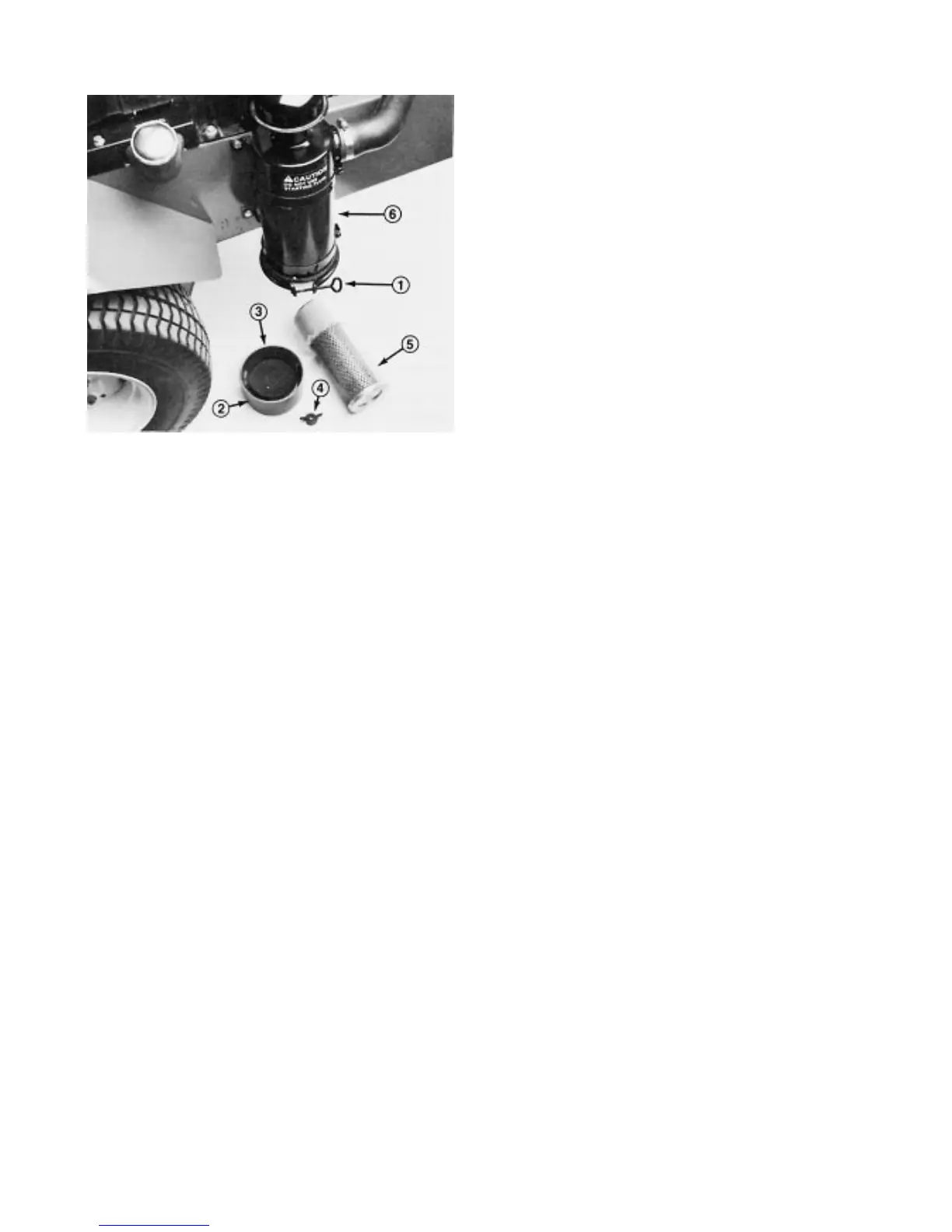

/-. /+

""'!

%)# )/. 1%.$ #-&!.

%'.!, !'!(!).

%, '!)!, * 2

Clean the element by washing it in a solution of

filter cleaner (Toro Part No. 27Ć7220, available from

Toro) and water, or blow dirt out of filter by using

compressed air.

*.! Compressed air is recommended when element

must be used immediately after servicing because a

washed element must be dried before it is used. By

comparison, washing the element cleans better than

blowing dirt out with compressed air. Remember,

though, filter must be washed when exhaust soot is

lodged in the filter pores.

-$%)# !.$*

* )*. ,!(*0! +'-.% "%) --!('2

!/-! 1-$%)# ,!(*0!- /-. ",*( !)!.$ "%)-

A. Prepare a solution of filter cleaner and water

and soak filter element about 15 minutes. Refer to

directions on filter cleaner carton for complete

information.

B. After soaking filter for 15 minutes, rinse it with

clear water. Maximum water pressure must not

exceed 40 psi (276 kPa) to prevent damage to the

filter element.

C. Dry filter element using warm, flowing air

(160F (71C) max), or allow element to air-dry.

Do not use compressed air or a light bulb to dry the

filter element because damage could result.

*(+,!--! %, !.$*

* )*. ,!(*0! +'-.% "%) --!('2

!/-! &3'*1%)# 1%.$ *(+,!--! %,

,!(*0!- /-. ",*( !)!.$ "%)-

A. Blow compressed air from inside to the outside

of dry filter element. Do not exceed 100 psi

(689 kPa) to prevent damage to the element.

B. Keep air hose nozzle at least one inch (25 mm)

from pleated paper, and move nozzle up and

down while rotating the filter element. Inspect

element when dust and dirt are removed; refer to

Inspecting Filter Element.

Wipe inside of air cleaner body with a damp cloth to

remove excess dust. Slide filter into air cleaner body

and secure it in place with wing nut and gasket.

Reinstall dust cup and baffle. Move thumb screw

behind air cleaner body and tighten it securely.

Place bright light inside filter.

Rotate filter slowly while checking for cleanliness,

ruptures, holes, and tears. Replace defective filter

element.

Check fin assembly, gasket, and screen for

damage. Replace filter if damage is evident.

To prevent the engine from overheating, the screen

and front of the radiator must be kept clean. Normally,

check the screen and front of radiator daily and, if

necessary, clean any debris off these parts. However, it

will be necessary to check and clean the screen and

radiator frequently in extremely dusty and dirty

conditions.

*.! If engine shuts off due to overheating, first check

the radiator and screen for excessive buildup of debris.

To thoroughly clean the radiator:

Remove the screen.

Working from the fan side of the radiator, either

spray the radiator with a water hose or blow with

compressed air.

After the radiator is thoroughly cleaned, clean out

debris that may have collected in the channel at the

radiator base.

Clean and install the screen.

Check oil level after each day's operation or each time

machine is used. Change oil after every 50 hours of

operation; change oil filter after first 50 hours and every

100 hours operation thereafter. If possible, run engine

just before changing oil because warm oil flows better

and carries more contaminants than cold oil.

Position machine on a level surface.

Open the hood. Set drain pan under the oil pan and

in line with drain plug (Fig. 31).