16

Pushing the Traction Unit Off

of the Pallet

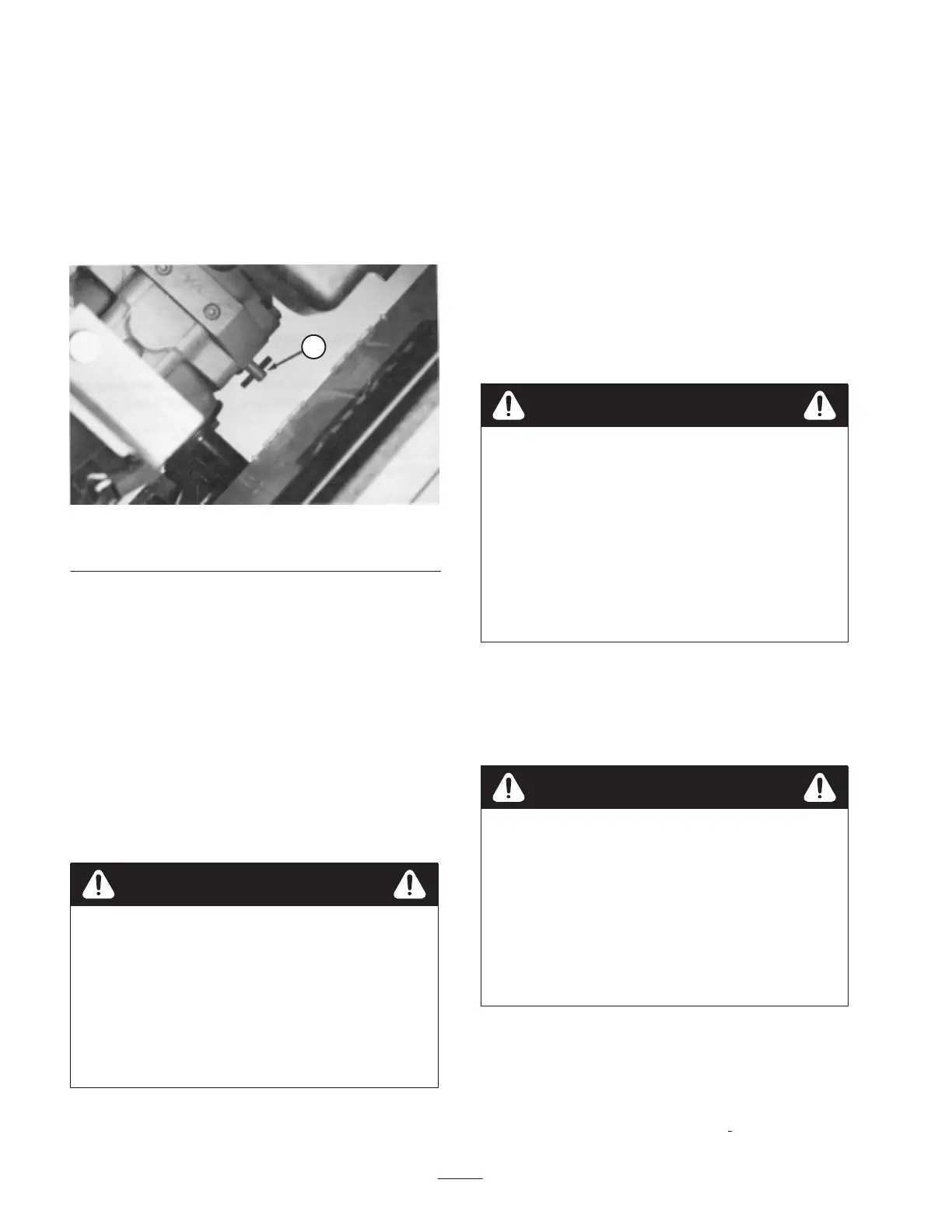

1. Reach in and rotate bypass valve on transmission

(Fig. 9) counterclockwise 1/2 to 1 turn. Opening the

valve opens an internal passage in the pump, thereby

bypassing transmission oil. Because fluid is bypassed,

the machine can be pushed without damaging the

transmission.

1

Figure 9

1. Bypass valve

2. Lift machine over shipping braces and push machine off

pallet.

3. Close bypass valve by rotating it clockwise until it is

securely seated. Do not exceed 5 to 8 ft.-lb. (7 to

11 N⋅m). Do not start engine when valve is open.

Activating and Charging the

Battery

1. If battery is not filled with electrolyte or charged, bulk

electrolyte with 1.280 specific gravity @ 77° F

(25°C) must be purchased from a local battery supply

outlet.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

2. Remove filler caps from battery and slowly fill each

cell until electrolyte is just above the plates. Install filler

caps.

3. Connect a 3 to 4 amp. battery charger to the battery

posts. Charge the battery at a rate of 3 to 4 amperes for

4 to 8 hours.

4. When battery is fully charged, disconnect charger from

electrical outlet and battery posts.

5. Remove filler caps and slowly add electrolyte to each

cell until level is up to fill ring. Install fill caps.

Installing the Battery in the

Chassis

Battery terminals or metal tools could short

against metal machine components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the machine.

• Do not allow metal tools to short between the

battery terminals and metal parts of the

machine.

Warning

1. Install battery and secure with hold down strap and

wing nuts (Fig. 3). Remove tape over ends of each

cable.

2. Slide the red, positive battery cable (Fig. 3) onto

positive battery post and tighten nut securely.

Incorrect battery cable routing could damage the

machine and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

Warning

3. Slide the black, negative battery cable (Fig. 3) onto

negative battery post and tighten nut securely.

4. Coat both battery connections with either Grafo 112X

(skin-over) grease, Toro Part No. 505-47, petroleum

jelly or light grease to prevent corrosion and slide

rubber boot over positive terminal (Fig. 3).