5.Turnthesquareheadadjustingboltontheframe

clockwisetotightenthebelt;turnitcounter

clockwisetoloosenthebelt.

Important:Important:Makesuretotighten

allengineboltsafterproperbeltadjustment

isachieved.

6.Installthebeltguardandsecurewithpreviously

removedhardware.

ReplacingtheDriveBelt

1.Removethe2bolts,2washers,andbeltguard

(Figure23).

2.Loosenthe4enginemountingbolts,andjam

nutsholdingtheadjustmentbolt(Figure25).

3.Removethebelt.

4.Installthenewbeltaroundthepulleys.

5.Tightenthejamnutonthetensionerbolt.

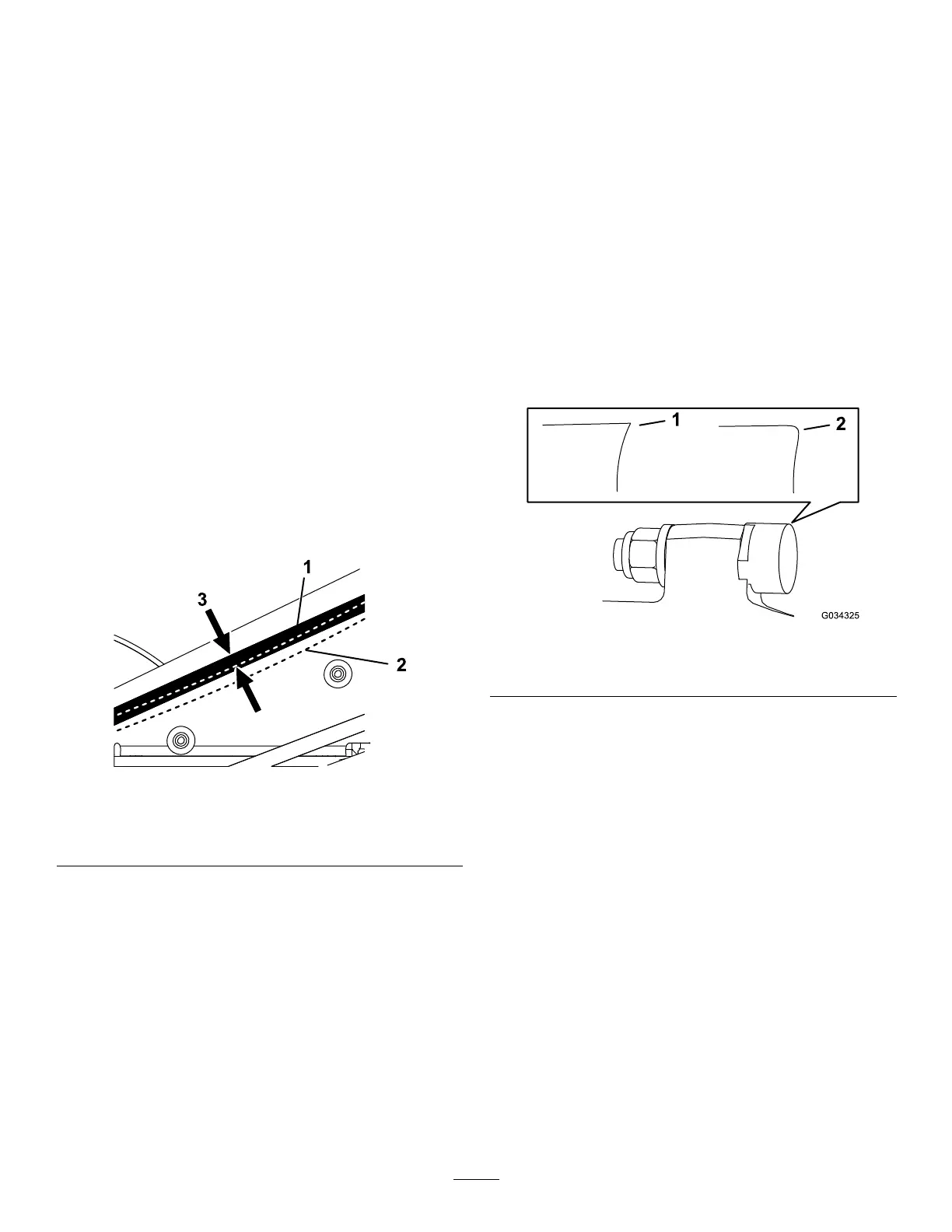

6.Pushdownonthebelttocheckthetension.You

shouldbeabletopushthenewbeltdown5.6

mm(0.22inch)using3.4kg(7.4lb)offorce.

Adjustthetensionerboltasnecessarytotighten

orloosenthebelt.

g244102

Figure26

1.Belt

3.5.6mm(0.22inch)

2.Beltpusheddown

7.Tightenthefastenerssecuringtheenginetothe

frame(Figure25).

Note:Ensurethattheenginedoesnottwistin

thechassisandtheclutchpulleyisalignedwith

thebelt.

8.Installthebeltguard(Figure23).

GrinderMaintenance

ReplacingtheTeeth

ServiceInterval:Beforeeachuseordaily—Check

theconditionoftheteeth;rotate

orreplaceanythatarewornor

damagedandtorquethenutsforall

teeth.

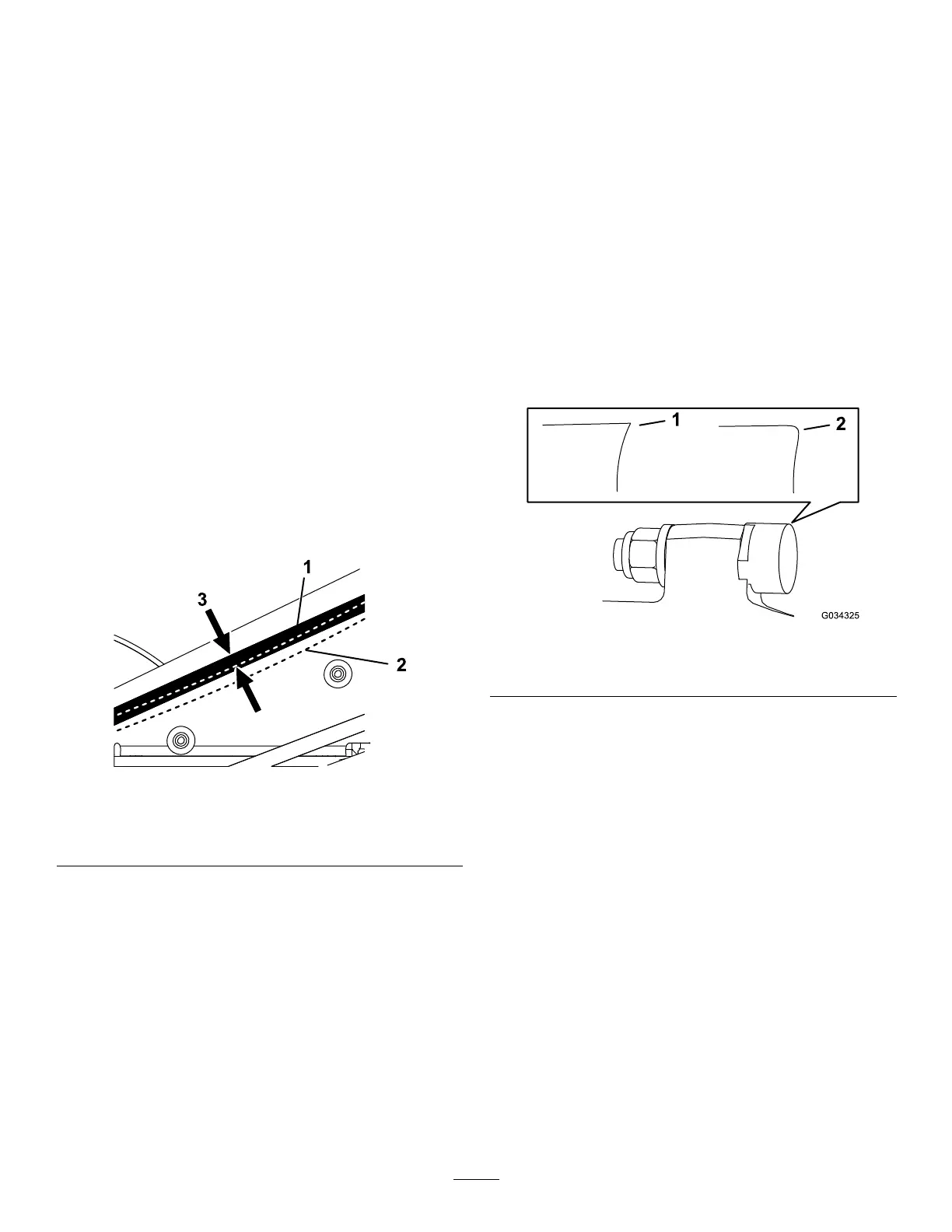

Duetothehighamountofwearplacedontheteeth,

youneedtorotateandreplacethemperiodically

(Figure27).Beforeyourotateorreplacethem,

inspecteachtoothholderonthewheel,includingthe

atlandsthatpreventtheteethfromrotating.Ifthe

toothholderisdamaged,replacethewheel.Torque

thenuts68N∙m(50ft-lb)foranyteeththatyouare

notrotatingorreplacing.

g034325

Figure27

1.Sharptooth

2.Worntooth

Eachtoothisindexedwith3positionssoyoucan

rotateittwice,exposinganewsharpedgebefore

replacingthetooth.T orotateatooth,loosenthenut

securingthetooth(Figure28).Pushthetoothforward

androtateit1/3ofaturn,bringinganunusededgeto

theoutside.T orquethenutsecuringthetoothto68

N∙m(50ft-lb).

Toreplaceatooth,removethenutsecuringthetooth,

theninstallanewtooth,washer,andnutinthesame

position(Figure28).T orquethenutsecuringthetooth

to68N∙m(50ft-lb).

21

Loading...

Loading...