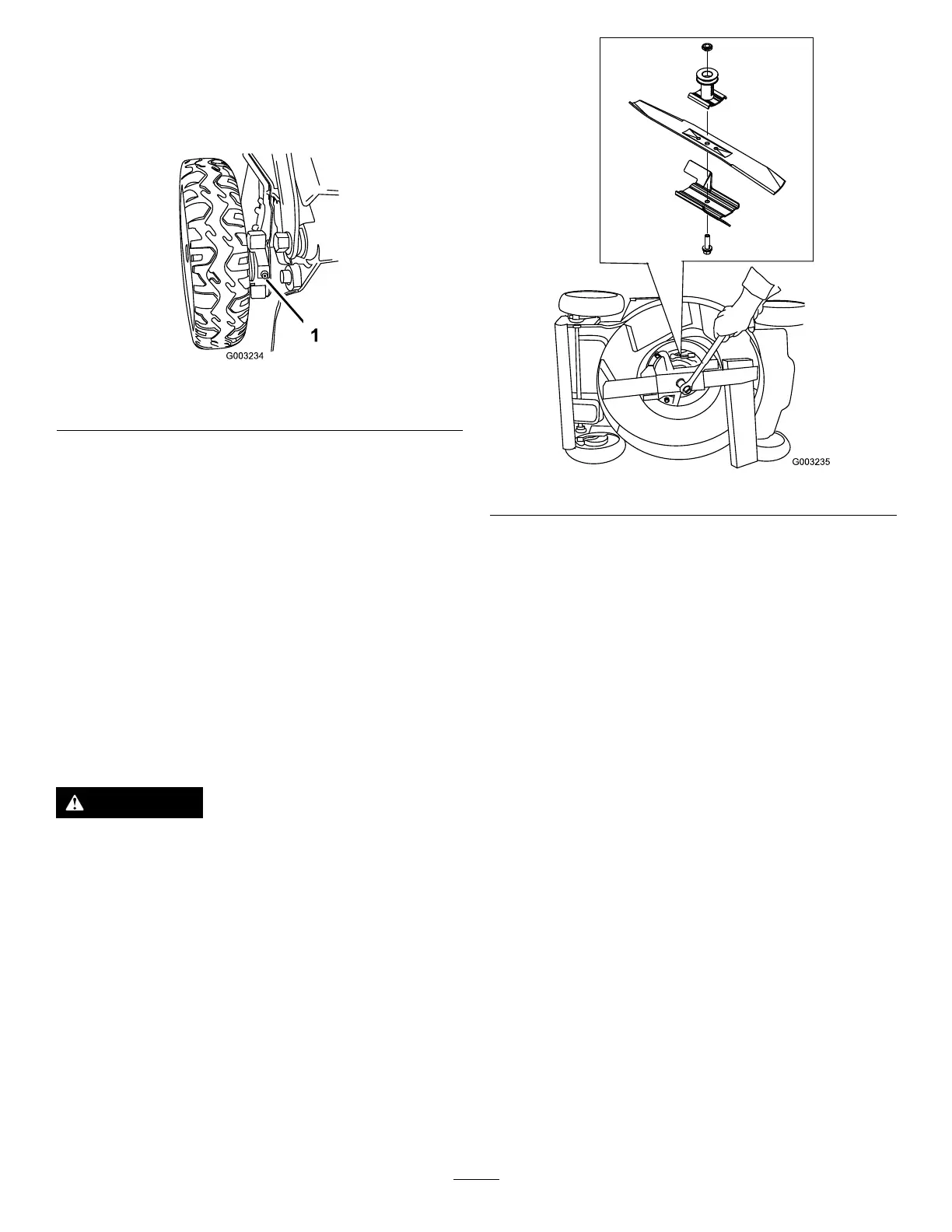

LubricatingtheWheelGears

ServiceInterval:Every25hours

1.Wipethegreasettingsjustinsidetherearwheelswith

acleanrag(Figure37).

Figure37

1.Greasetting

2.Installagreasegunontoeachttingandgentlyapply2

or3pumpsof#2multi-purpose,lithium-basedgrease.

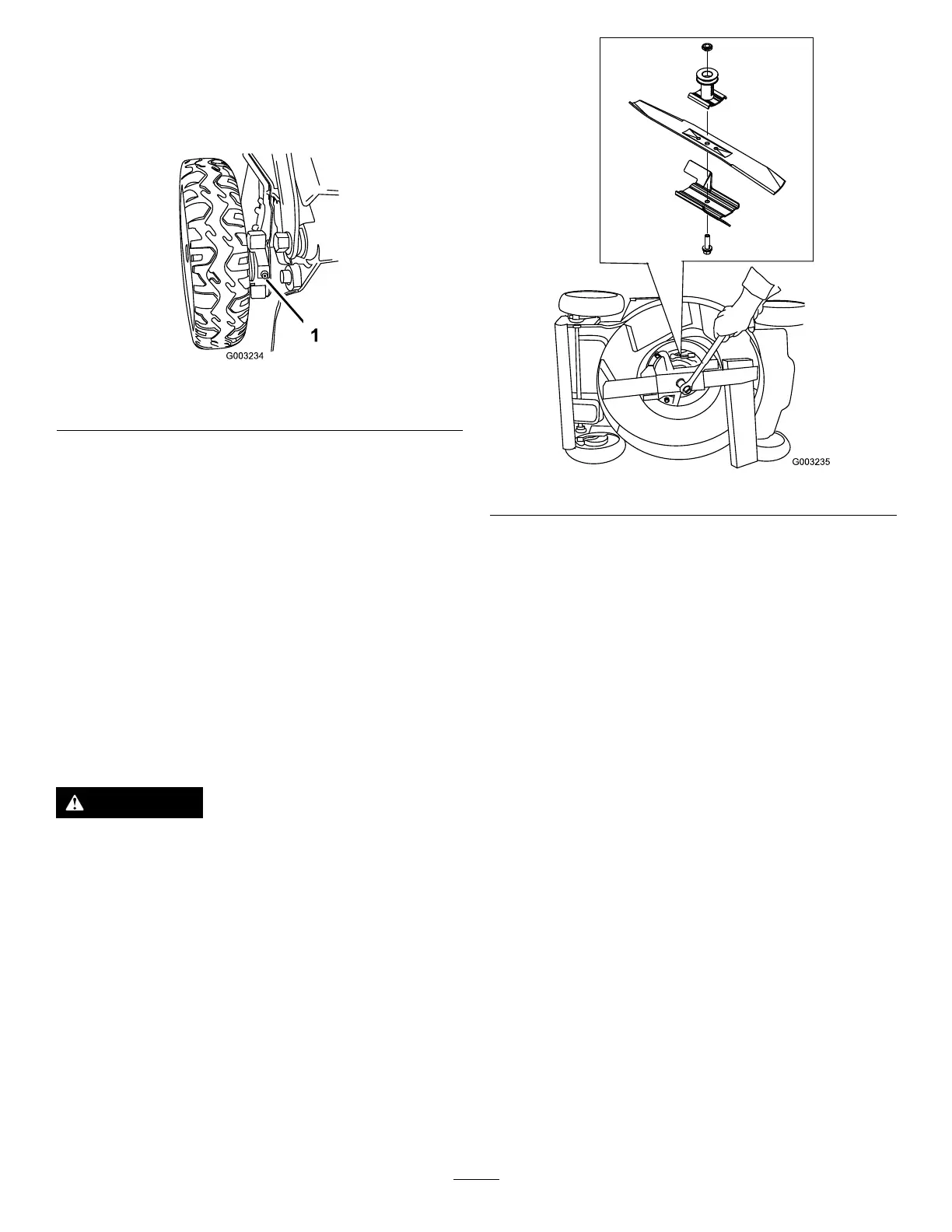

ReplacingtheBlade

ServiceInterval:Beforeeachuseordaily

Every25hours—Replacethebladeorhaveit

sharpened(morefrequentlyiftheedgedullsquickly).

Important:

Y ou will need a torque wr ench to install the

blade pr oper l y

.Ifyoudonothaveatorquewrenchor

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladewheneveryourunoutofgasoline.Ifthe

bladeisdamagedorcracked,replaceitimmediately.Ifthe

bladeedgeisdullornicked,haveitsharpenedorreplaceit.

WARNING

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

Weargloveswhenservicingtheblade.

1.Disconnectthesparkplugwirefromthesparkplug.

RefertoPreparingforMaintenance(page16).

2.Tipthemachineontoitssidewiththedipstickdown.

3.Useablockawoodtoholdthebladesteady(Figure38).

Figure38

4.Removetheblade,savingallmountinghardware.

5.Installthenewbladeandallmountinghardware.

Important:Positionthecurvedendsoftheblade

topointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladeboltto

82N-m(60ft-lb).

Important:Abolttorquedto82N-m(60ft-lb)is

verytight.Whileholdingthebladewithablock

ofwood,putyourweightbehindtheratchetor

wrenchandtightentheboltsecurely.Thisboltis

verydifculttoovertighten.

18

Loading...

Loading...