3.Measurefromthetipofthebladetothelevel

surface.

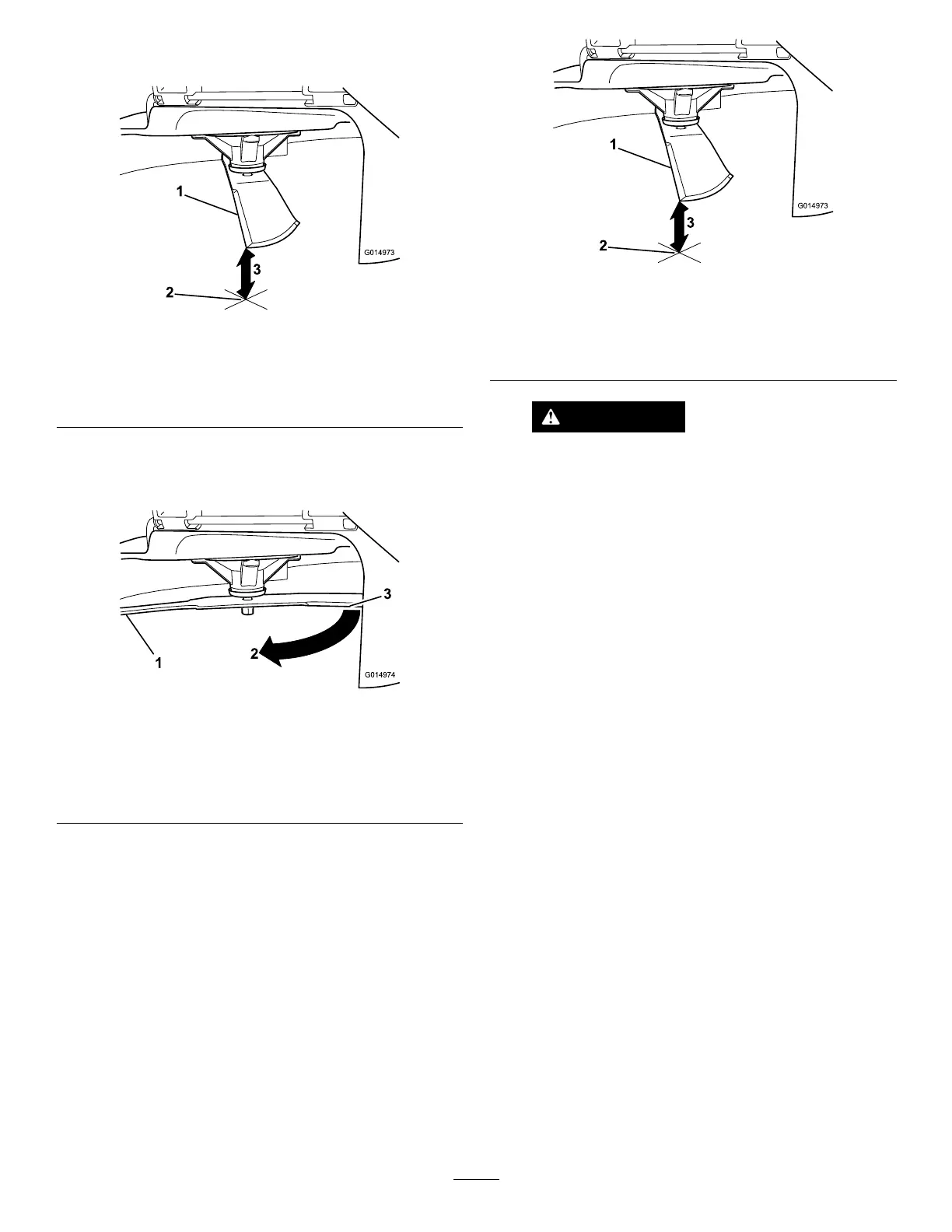

g014973

Figure55

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothat

theopposingcuttingedgeisnowinthesame

position.

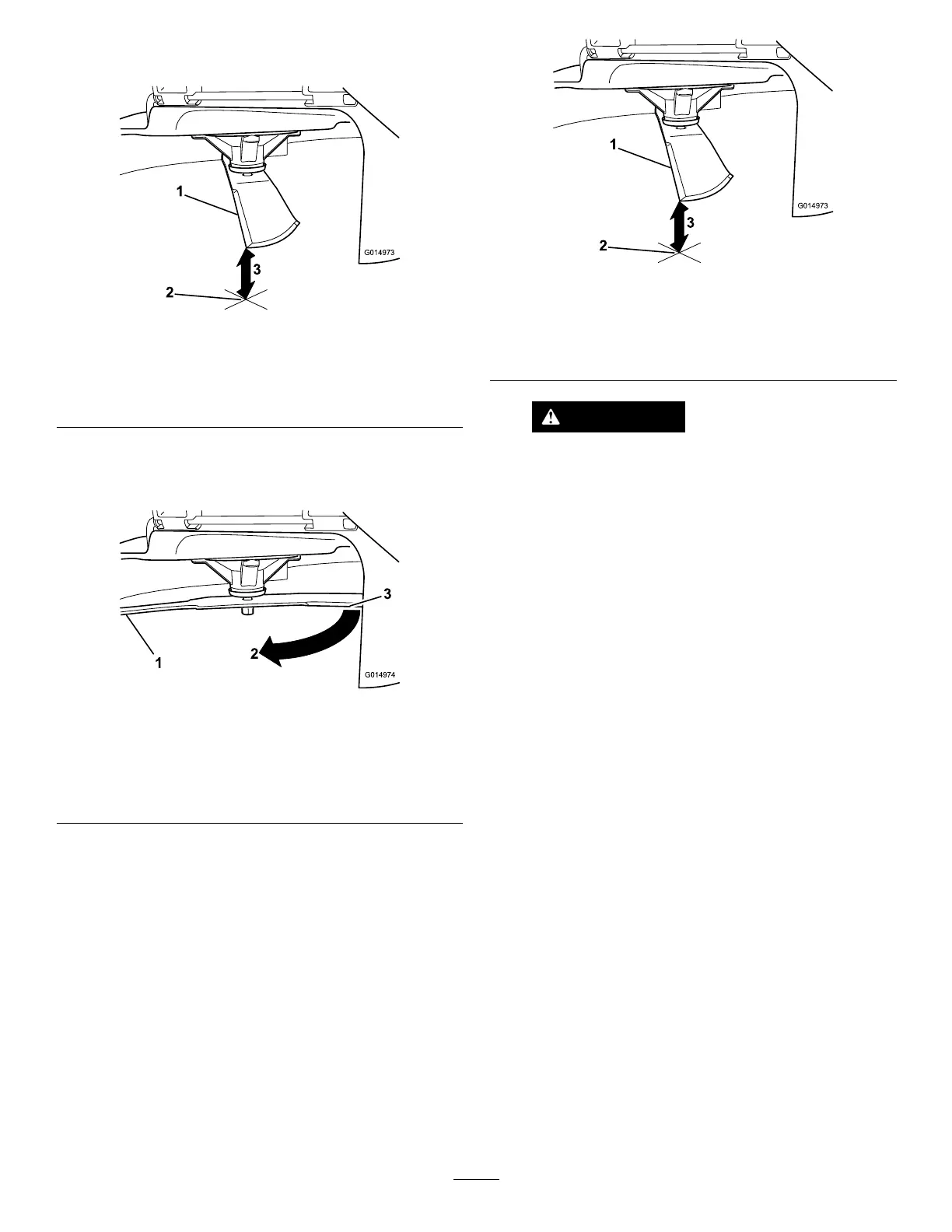

g014974

Figure56

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheat

surfacehere.

Note:Themeasuredvarianceshouldbeno

morethan3mm(1/8inch).

g014973

Figure57

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

•Alwaysreplaceabentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesoftheblade.

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch)replacethebladewith

anewblade;refertoRemovingtheBlades

(page45)andInstallingtheBlades(page

46).

Note:Ifabentbladeisreplacedwithanew

oneandthedimensionobtainedcontinues

toexceed3mm(1/8inch),thebladespindle

couldbebent.ContactanAuthorizedToro

Dealerforservice.

B.Ifthevarianceiswithinconstraints,move

tostep6.

6.Performsteps2,3,4,and5ontheotherblade.

RemovingtheBlades

Replaceabladewheneveritstrikesanobject,

isoutofbalance,orisbent.T oensureoptimum

performanceandcontinuedsafetyconformanceofthe

machine,useonlygenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

Holdthebladeendusingaragorthickly-padded

glove.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure58).

45

Loading...

Loading...