Figure23

1.Spark-plugwire

6.Cleanaroundthesparkplugtopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

7.Removethesparkplugandmetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure24).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

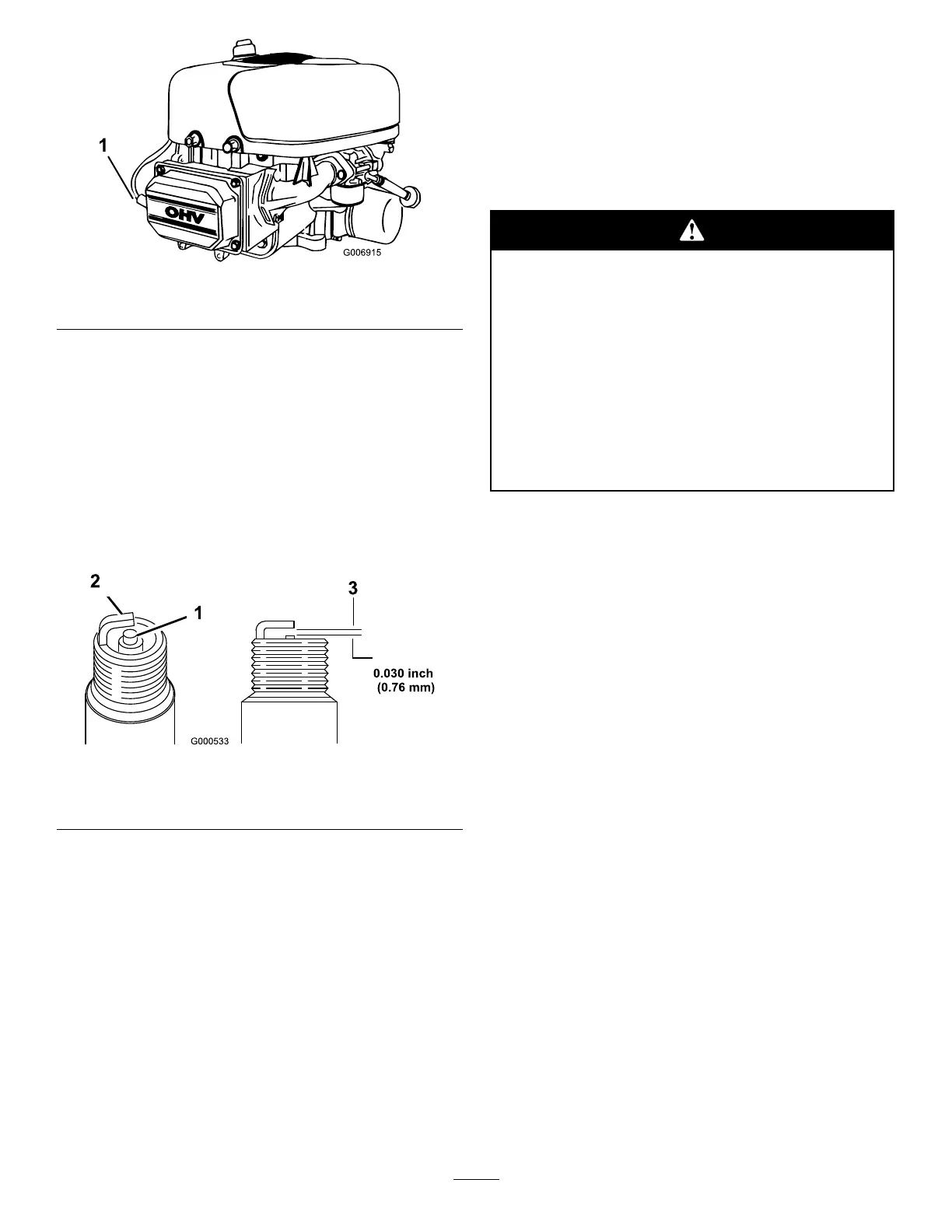

Figure24

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure24).Bendthesideelectrodeifthegapisnot

correct.

InstallingtheSparkPlug

1.Installthesparkplugandmetalwasher.

Note:Ensurethattheairgapissetcorrectly.

2.Tightenthesparkplugto15ft-lb(20N⋅m).

3.Connectthewiretothesparkplug(Figure23).

4.Closethehood.

FuelSystem

Maintenance

DrainingtheFuelTank

ServiceInterval:Beforestorage

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

1.Parkthetractorsothattheleftfrontsideisslightly

lowerthantherightsidetoensurethatthefueltank

drainscompletely.

2.Disengagethebladecontrol(PTO).

3.Settheparkingbrake.

4.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

5.Openthehoodandlocatethefuellter(Figure25).

22

Loading...

Loading...