E6581386

A-18

1

Method of lubricating load mechanisms

Operating an oil-lubricated reduction gear and gear motor in the low-speed areas will worsen the lubricating effect.

Check with the manufacturer to find out about operable speed range.

Low loads and low inertia loads

The motor may demonstrate instability such as abnormal vibrations or overcurrent trips at light loads of 5% or

under of the rated load, or when the load's moment of inertia is extremely small. If that happens reduce the carrier

frequency.

Occurrence of instability

Unstable phenomena may occur under the load and motor combinations shown below.

• Combined with a motor that exceeds applicable motor ratings recommended for the inverter

• Combined with special motors

To deal with the above lower the settings of inverter carrier frequency. (When performing vector control, set the

carrier frequency at 2kHz or more. If the carrier frequency is set below 2kHz, it will be automatically corrected to

2kHz by the inverter.)

Minimum carrier frequency for 200V-55kW and above, 400V-90kW and above models is 2.5kHz.

• Combined with couplings between load devices and motors with high backlash

In this case, set the S-pattern acceleration/deceleration function and adjust the response time inertial moment

setting during vector control or switch to V/f control (

=).

• Combined with loads that have sharp fluctuations in rotation such as piston movements

In this case, adjust the response time inertial moment setting during vector control or switch to V/f control (

=).

Braking a motor when power supply is lost

A motor with its power cut off goes into freewheel, and does not stop immediately. To stop the motor quickly as

soon as the power is cut off install an auxiliary brake. There are different kinds of brake devices, both electrical and

mechanical. Select the brake that is best for the system.

Loads that generate negative torque

When combined with loads that generate negative torque the protection for overvoltage and overcurrent on the

inverter will go into operation and may cause a trip. For this kind of situation, you must install a dynamic braking

resistor, etc. that complies with the load conditions.

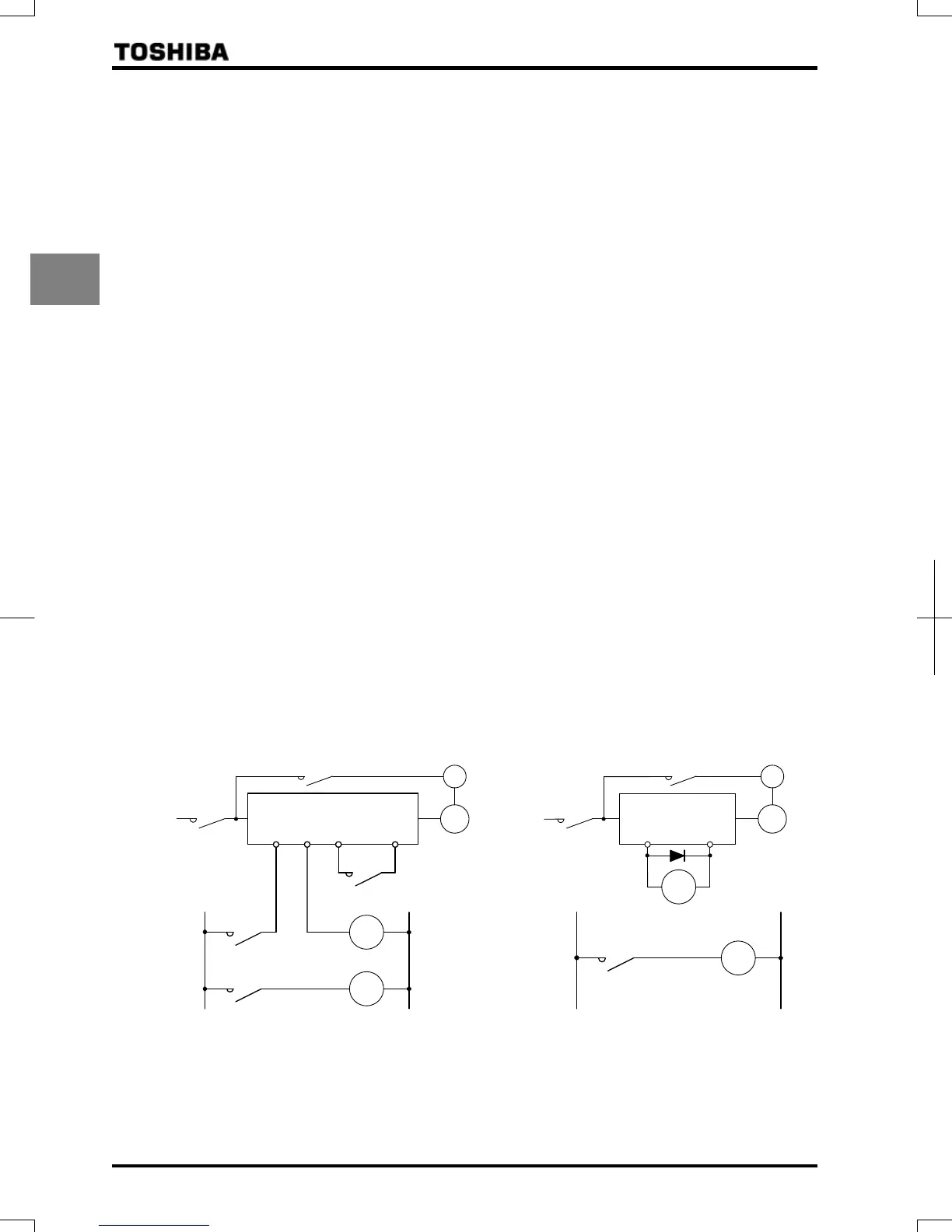

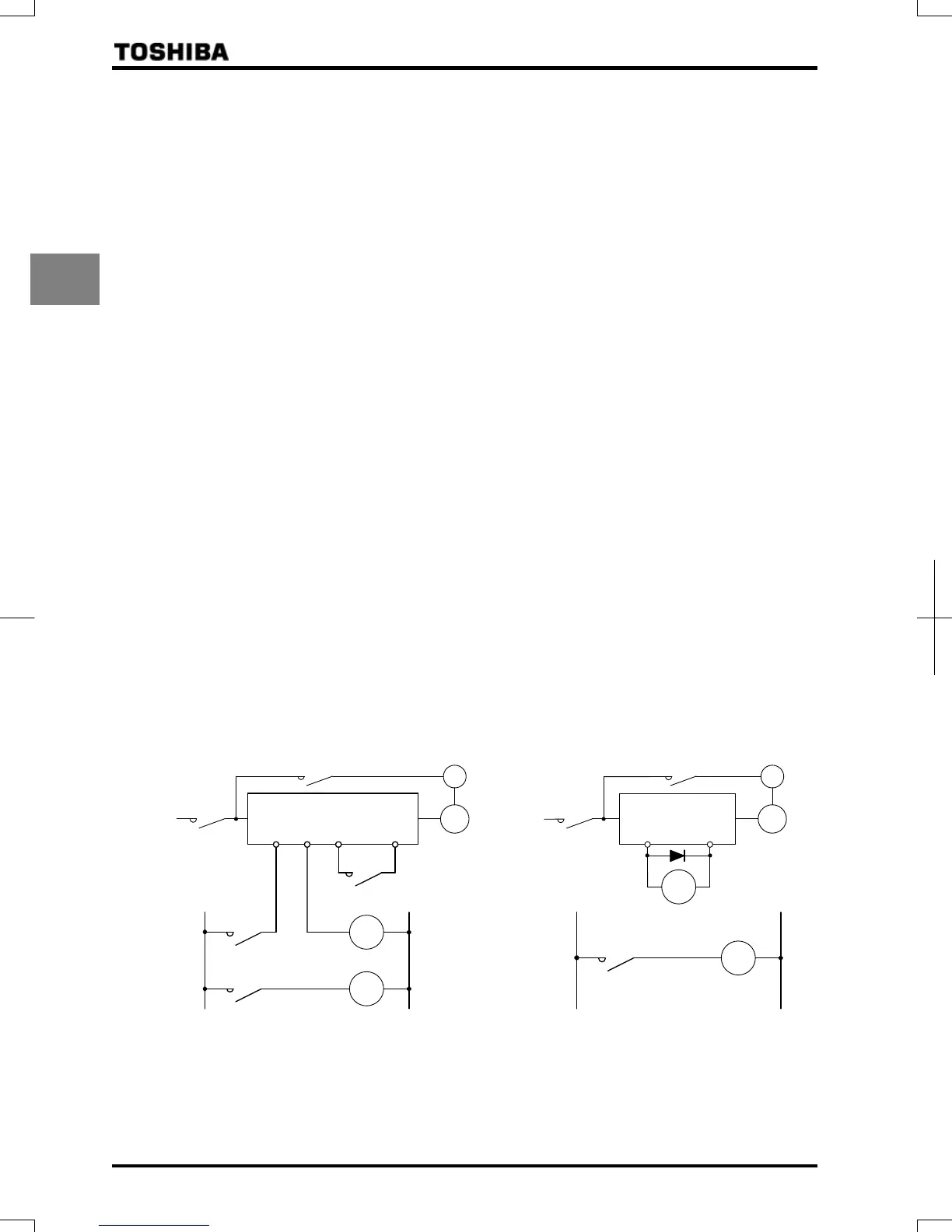

Motor with brake

If a brake motor is used with the braking circuit connected to the output terminals of the inverter, the brake cannot

be released because of a voltage drop at startup. Therefore, when using the inverter along with a brake motor,

connect the braking circuit to the power supply side of the inverter, as shown in the figure below. In most cases, the

use of a brake motor causes an increase in noise at low-speed.

B

IM

LOW

OUT1

P24

Three-

phase

power

supply

MC2

MC3

MC2

MC1

MC2

B

IM

MC3

MC1

MC3

FLB

FLC

PWR

P24

Three-

phase

power

supply

LOW

(Non-exciting brake)

(Non-exciting brake)

MC1

MC2

Circuit configuration 1 Circuit configuration 2

Loading...

Loading...