15

Installation (Continued)

Rigging

A Rigging illustration and Center-of-Gravity dimensional

data table is shown in Figure 3-3. Refer to the typical unit

operating weights table before proceeding.

1. Rig the condensing unit as shown in Figure 3-3. Attach

adequate strength lifting slings to all four lifting brackets

in the unit base rail. Do not use cables, chains, or slings

except as shown.

2. Install spreader bars, as shown in Figure 3-3, to protect

the unit and to facilitate a uniform lift. The minimum dis-

tance between the lifting hook and the top of the unit

should be 7 feet.

3. Test-lift the unit to ensure it is properly rigged and bal-

anced, make any necessary rigging adjustments.

4. Lift the unit and position it into place.

Unit Isolation

To minimize unit sound and vibration transmission, one of

the following installation methods should be used:

1. Install the unit directly on an isolated (detached) concrete

pad or on isolated concrete footings located at each unit

load point.

2. Install the optional neoprene or spring isolators at each

mounting location. Refer to the following “Neoprene iso-

lators” or “Spring Isolator” section.

Neoprene Isolators

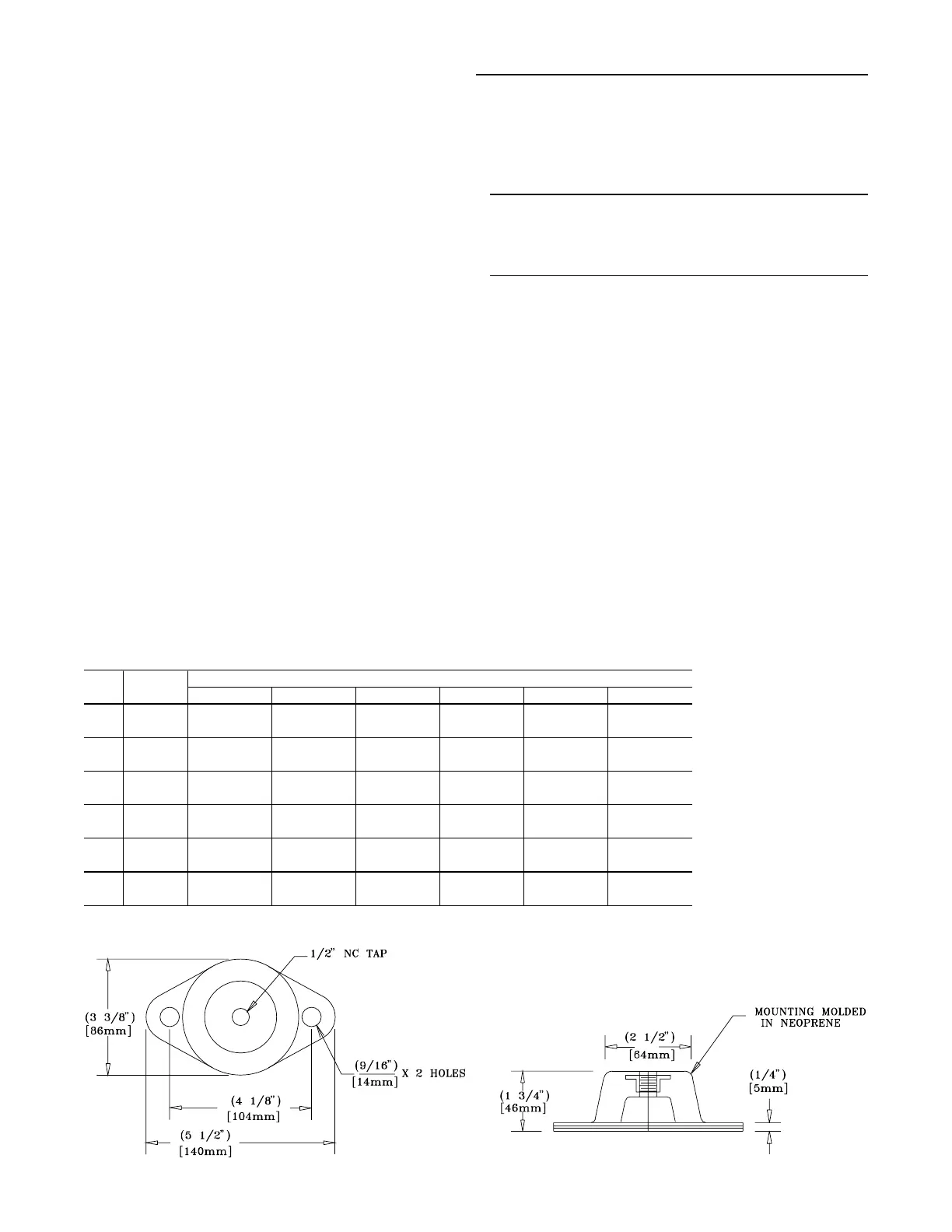

Install the neoprene isolators at each unit mounting (load)

point, using the following procedure:

1. Elevate the unit (one side at a time) to allow access to

the base rail mounting holes.

Note: Use solid type blocks, i.e. 4" X 4" wood

blocks or similar material to prevent collapsing.

Keep hands and other body limbs clear of elevated

base rail while installing isolators to prevent

personal injury.

2. Align the mounting holes in the base rail of the unit with

the holes in the top of the appropriate isolator. Refer to

Figure 3-4 for the appropriate isolator for each load point.

3. Install a 1/2" NC bolt (field supplied) through the base rail

of the unit into the threaded bolt hole of the isolator. Po-

sition the isolator to allow access to the mounting holes

in the base of the isolator, then tighten securely.

4. Lower the unit and isolator onto the mounting surface.

The maximum isolator deflection should be approxi-

mately 1/4 inch.

5. Secure the isolator to the mounting surface using the

base holes in the isolator.

6. Level the unit carefully. Refer to the “Leveling the Unit”

section.

7. After the unit is level, tighten the isolator base mounting

bolts to secure them to the mounting surface.

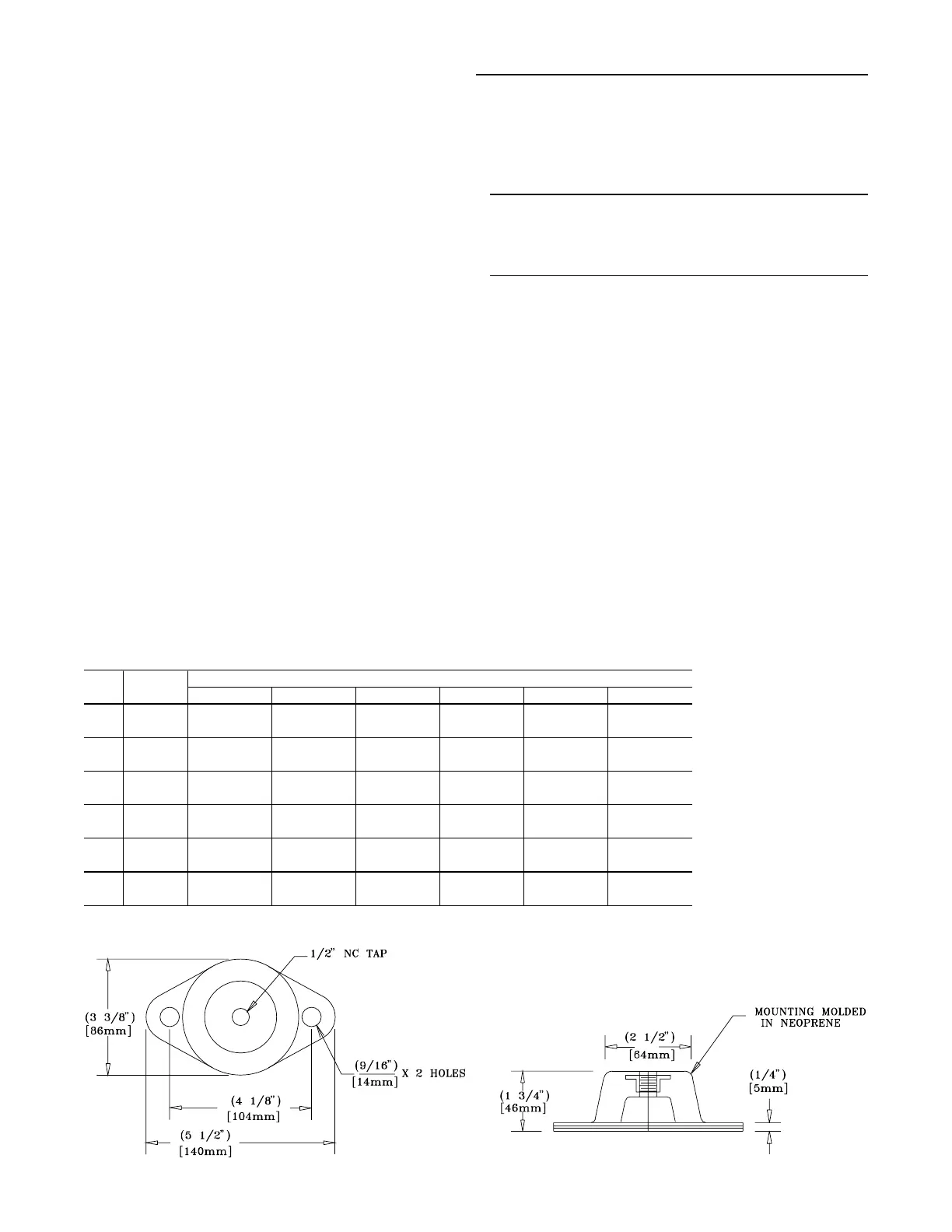

Figure 3-4

Typical Neoprene Isolator Selection & Location

Unit Fin Neoprene Isolator Part Number @ Mounting Location

Size Material Location 1 Location 2 Location 3 Location 4 Location 5 Location 6

C20 Al RDP-3-RED RDP-3-RED RDP-3-RED RDP-3-RED

Cu RDP-3-GRN RDP-3-RED RDP-3-RED RDP-3-RED

C25 Al RDP-3-RED RDP-3-RED RDP-3-RED RDP-3-RED

Cu RDP-3-GRN RDP-3-GRN RDP-3-RED RDP-3-RED

C30 Al RDP-3-RED RDP-3-GRN RDP-3-RED RDP-3-RED

Cu RDP-3-GRN RDP-3-GRN RDP-3-RED RDP-3-GRN

C40 Al RDP-3-RED RDP-3-RED RDP-3-RED RDP-3-RED RDP-3-RED RDP-3-RED

Cu RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN

C50 Al RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-RED RDP-3-RED

Cu RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN

C60 Al RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN

Cu RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN RDP-3-GRN

Notes:

1. Mounting locations correlate with those shown in point loading illustration.

Loading...

Loading...