44

CVHE-SVX02M-EN

Insulation

Unit Insulation Requirements

Factory-installed insulation is available as an option for

all units. Factory installation does NOT include

insulation of the chiller feet; if required, insulation for

chiller feet is provided by others. In applications where

the chiller is not factory-insulated, install insulation

over the areas outlined and highlighted with dashed

lines as shown in Figure 28, p. 45.

Insulate all 1/4-in. (6.35-mm) eductor lines, one from

the suction cover and one from the evaporator, to

prevent sweating.

The quantities of insulation required based on unit size

and insulation thickness are listed in the following

table. Insulation thickness is determined at normal

design conditions which are:

• Standard comfort-cooling leaving chilled water

temperature

• 85°F (29.4°C) dry bulb ambient temperature

• 75 percent relative humidity

Operation outside of normal design conditions as

defined in this section may require additional

insulation; contact Trane for further review.

NNoottee:: If the unit is not factory-insulated, install

insulation around the evaporator bulbwells and

ensure that the bulbwells and connections for

the waterbox drains and vents are still accessible

after insulation is applied. The sensor modules

(Low Level Intelligent Devices [LLIDs]) and

interconnecting four-wire cable inter-processor

communication (IPC) bus must be raised up

above the field-installed insulation. Secure the

IPC bus to the insulation top/outer surface after

insulation is completed.

IImmppoorrttaanntt:: Do NOT insulate the motor housing, unit

wiring, or sensor modules.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

FFaaiilluurree ttoo rreemmoovvee tthhee ssttrraaiinn rreelliieeff wwiitthh tthhee sseennssoorr

ccoouulldd rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee..

DDoo NNOOTT aatttteemmpptt ttoo ppuullll sseennssoorr bbuullbb tthhrroouugghh tthhee

ssttrraaiinn rreelliieeff;; aallwwaayyss rreemmoovvee tthhee eennttiirree ssttrraaiinn rreelliieeff

wwiitthh tthhee sseennssoorr..

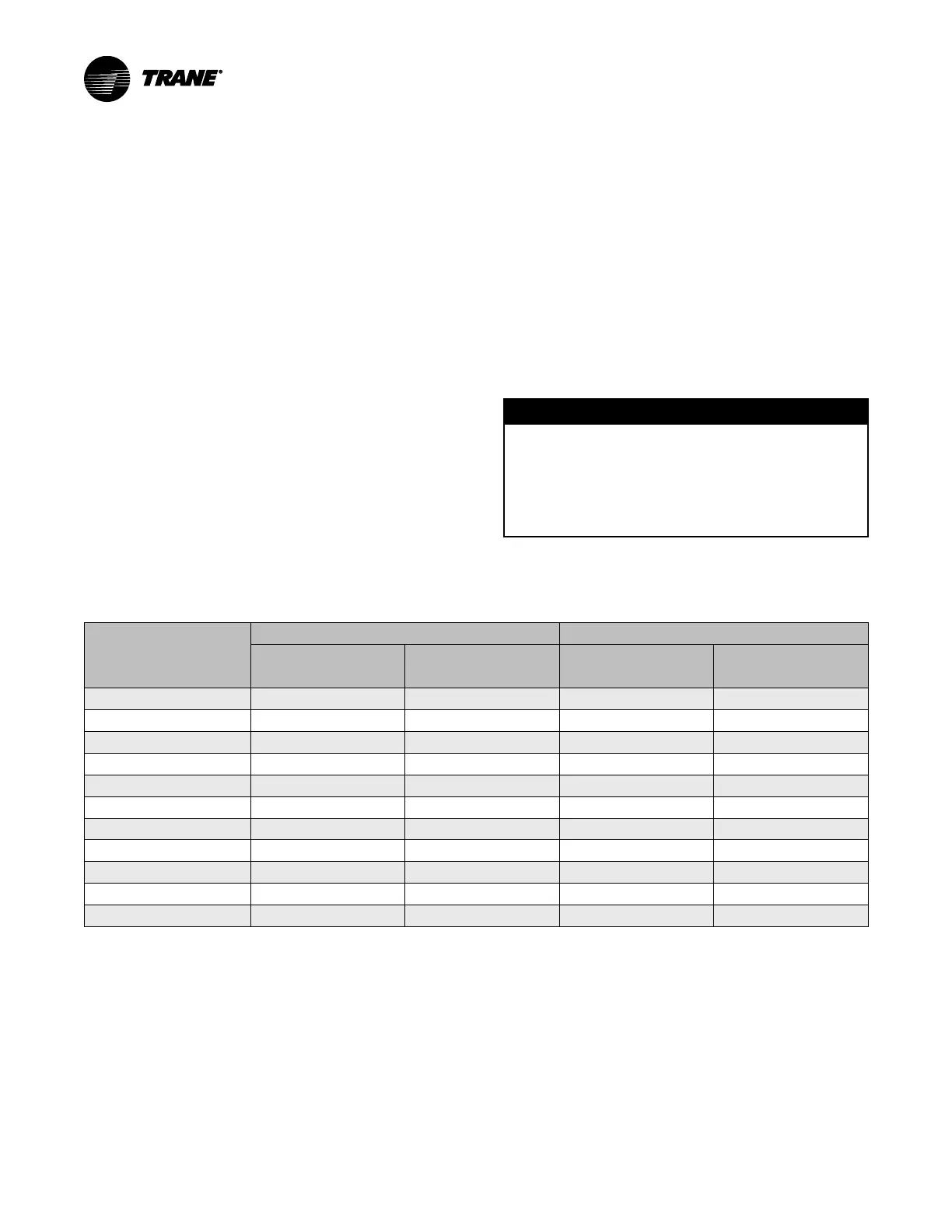

Table 13. Evaporator insulation requirements

EVSZ

(a)

Standard Unit

Free Cooling

3/4 in. (19.05 mm)

(a)

Insulation(Square

Feet)

3/8 in. (9.525 mm)

Insulation

(b)

(Square

Feet)

3/4-in. (19.05 mm)

Insulation

(a)

(Square Feet)

3/8 in. (9.525 mm)

Insulation

(b)

(Square

Feet)

032 Short 337 52 347 74

032 Long

365 52 377 74

050 Short 385 63 398 72

050 Long

420 63 436 72

080 Short 505 84 515 97

080 Long

553 84 566 97

142 Medium 555 98 555 133

142 Long

578 98 578 133

142 Extended 603 104 629 133

210 Long

700 98 710 133

250 Extended 770 97 780 133

NNoottee:: Chillers equipped with refrigerant pumps are NOT insulated on the motor or refrigerant drain lines.

(a)

3/4-in. (19.05-mm) sheet insulation is installed on the evaporator, evaporator waterboxes, suction elbow, and suction cover.

(b)

3/8-in. (9.525-mm) sheet insulation is installed on all economizers. All liquid lines and other pipes require the use of 1/2-in. (12.7-mm) pipe insulation or

3/8-in. (9.525-mm) sheet insulation. Copper oil eductor tube lines require pipe insulation.

Insulation Thickness

Requirements

Factory Applied Insulation

All low-temperature surfaces are covered with 3/4 in.

(19.05 mm) Armaflex® II or equal (thermal conductivity

= 0.28 Btu/h-ft

2

[1.59 W/m

2

-K]), including the

evaporator, waterboxes, and suction elbow. The

economizer and motor cooling lines are insulated with

3/8 in. (9.525 mm) and 1/2 in. (12.7 mm) insulation,

respectively.

The insulation is Armaflex® or equivalent closed cell

elastomeric insulation to prevent the formation of

condensation up to a dew point rating of 74°F (23.3°C),

K = 0.25. Chillers in high humidity areas or ice storage,

Loading...

Loading...