90

CVHE-SVX02M-EN

Figure 60. Waterbox rigging and lifting—condenser

and evaporator connections

Reassembly

Once service is complete, the waterbox should be

reinstalled on the shell following all previous

procedures in reverse. Use new O-rings or gaskets on

all joints after thoroughly cleaning each joint.

IImmppoorrttaanntt:: Torque waterbox bolts (refer to Table 24, p.

90).

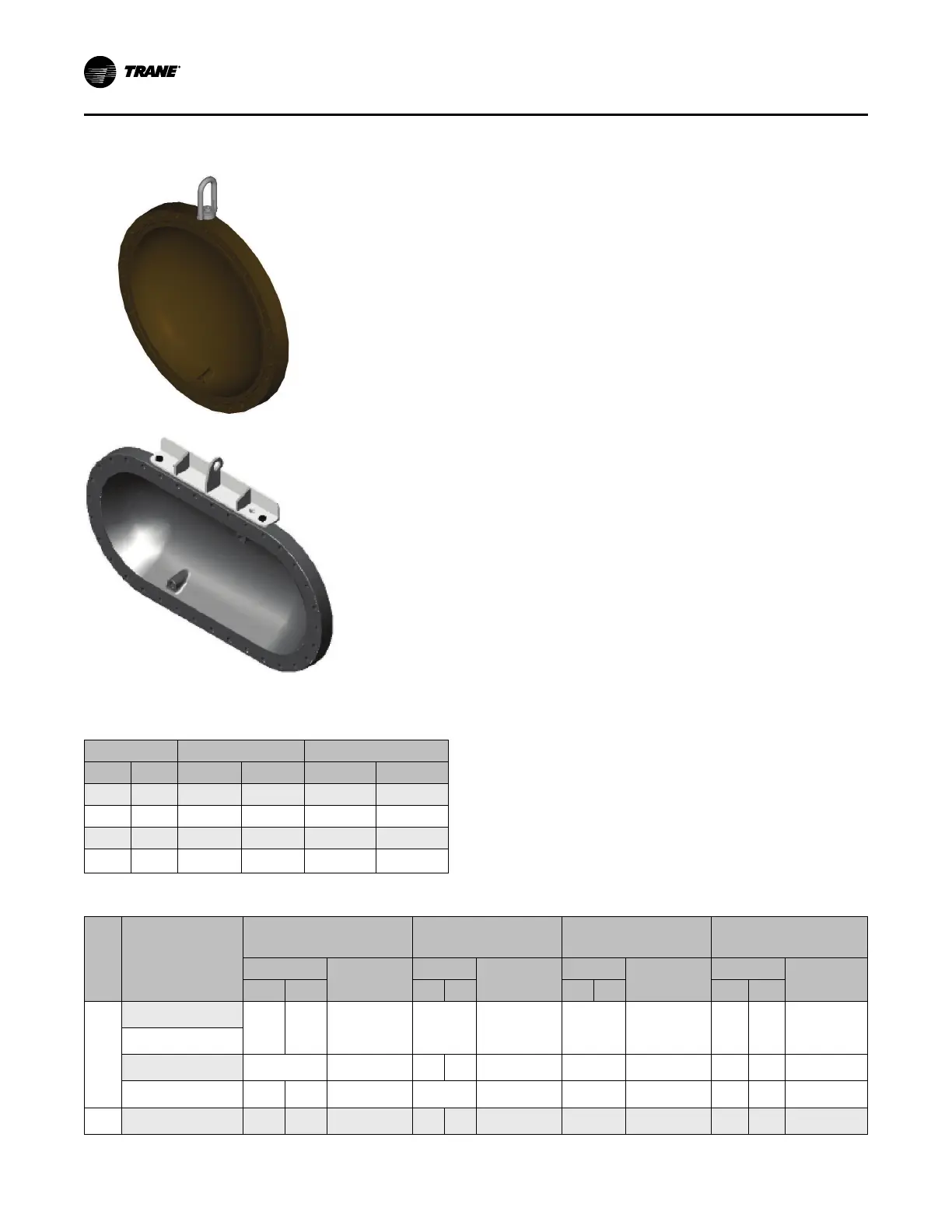

Torque Requirements and Waterbox Weights

Table 24. CenTraVac™™ chiller bolt torques

Bolt Size

Gasket type O-ring

Flat

in.

mm

ft·lb N·m ft·lb N·m

3/8

9.525 25 33.9 12–18 16.3–24.4

1/2

12.7 70 94.9 33–50 44.7–67.8

5/8

15.875 150 203.4 70–90 94.9–122.0

3/4

19.05 250 339.0 105–155

142.4–

210.2

Table 25. Waterbox weights

Shell

Size

Description

Fabricated Non-Marine

Waterbox, Welded Flat

Plate

Non-Marine Cast

Waterbox

Fabricated Non-

Marine Waterbox

Welded Dome

Marine Style Waterbox

Cover

Weight

Lifting

Connection

Weight

Lifting

Connection

Weight

Lifting

Connection

Weight

Lifting

Connection

lb

kg

lb

kg

lb

kg

lb

kg

032

Evaporator, 150 psig

(1034.2 kPaG)

265 120

3/4 - 10

— — — — 176 80

1/2 - 13

Evaporator, 300 psig

(2068.4 kPaG)

Condenser, 150 psig

(1034.2 kPaG)

— — 176 80

1/2 - 13

— — 176 80

1/2 - 13

Condenser, 300 psig

(2068.4 kPaG)

265 120

3/4 - 10

— — — — 221 100

1/2 - 13

050

Evaporator, 150 psig

(1034.2 kPaG)

397 180

3/4 - 10

397 180

Lifting Fixture

— — 265 120

1/2 - 13

WWaatteerrbbooxx RReemmoovvaall aanndd IInnssttaallllaattiioonn

Loading...

Loading...