18-CD20D1-18 19

Installer’s Guide

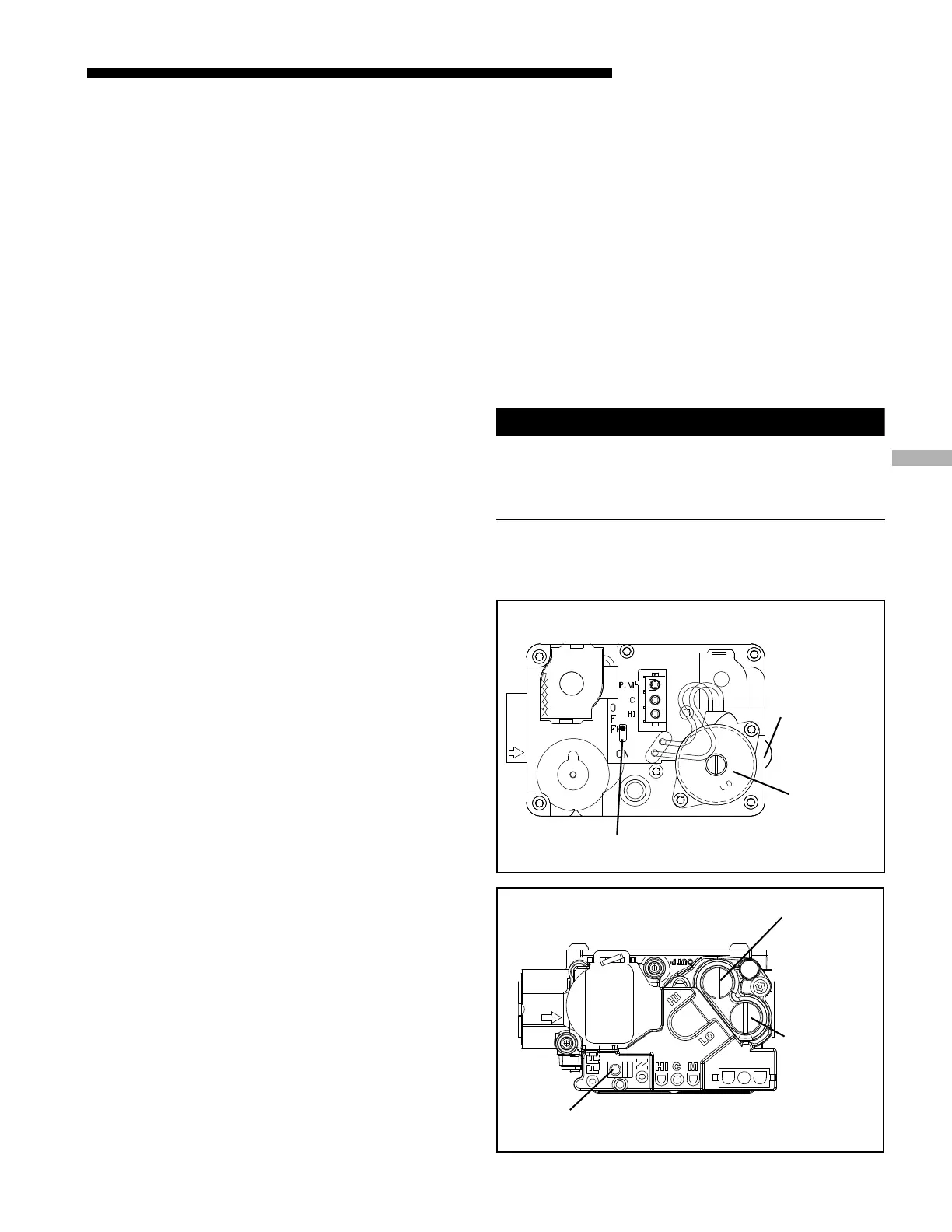

7. Changes can be made by adjusting the manifold pressure

(See Table 9), or changing orifices (orifice change may not

always be required). To adjust the manifold pressure:

a. Turn off all electrical power to the system.

b. Attach a manifold pressure gauge to the outlet

pressure tap marked “OUT PRESS TAP” on

White-Rodgers gas valve model 36E or boss marked

“OUT P” on White-Rodgers gas valve model 36G. (See

Figure 28 for White-Rodgers gas valve model 36E and

Figure 29 for White-Rodgers gas valve model 36G).

For the gas valve model 36E, measurements require

removal of the plug and installation of a barbed

fitting. Attach flexible tubing and a manometer to the

barbed fitting. For the gas valve model 36G, do not

remove the pressure tap test screw. Loosen the

pressure tap test screw one turn and install flexible

tubing and a manometer directly onto the outlet

pressure boss.

c. Turn on system power and energize valve.

d. For the White-Rodgers gas valve model 36E:

1. Adjust low fire by removing the low adjustment

seal screw (See Figure 28).

2. To increase outlet pressure, turn the 3/32" socket

set screw clockwise.

To decrease outlet pressure, turn the set screw

counterclockwise.

Adjust regulator until pressure shown on mano-

meter matches the pressure specified in Table 9.

3. Replace low adjustment seal screw and tighten

securely.

4. Cycle the valve several times to verify regulator

setting.

5. Adjust high fire by removing the high adjustment

regulator cover screw (See Figure 28).

6. To increase outlet pressure, turn the regulator

adjust screw clockwise. To decrease outlet pressure,

turn the regulator adjust screw counterclockwise.

The final manifold pressure setting shall be as

specified in Table 9 with an input of no more than

nameplate rating and no less than 93% of the

nameplate rating, unless the unit is derated for

high altitude.

7. Replace high adjustment regulator cover screw and

tighten securely.

8. Cycle the valve several times to verify regulator

setting.

e. For the White-Rodgers gas valve model 36G:

1. Adjust low fire by removing the low adjustment

regulator cover screw (See Figure 29).

2. To increase outlet pressure, turn the regulator

adjust screw clockwise. To decrease outlet pressure,

turn the regulator adjust screw counterclockwise.

Adjust regulator until pressure shown on manom-

eter matches the pressure specified in Table 9.

3. Replace and tighten the regulator cover screw

securely.

4. Cycle the valve several times to verify regulator

setting.

5. Adjust high fire by removing the high adjustment

regulator cover screw (See Figure 29).

6. To increase outlet pressure, turn the regulator

adjust screw clockwise. To decrease outlet pressure,

turn the regulator adjust screw counterclockwise.

The final manifold pressure setting shall be as

specified in Table 9 with an input of no more than

nameplate rating and no less than 93% of the

nameplate rating, unless the unit is derated for

high altitude.

7. Replace high adjustment regulator cover screw and

tighten securely.

8. Cycle the valve several times to verify regulator

setting.

f. Turn off all electrical power to the system.

g. Remove the manometer and flexible tubing. Remove

the barbed fitting and replace the plug or tighten the

pressure test screw.

h. Turn on electrical power to the system and energize

valve.

i. Using a leak detection solution or soap suds, check for

leaks at plug or pressure boss screw.

CAUTION

!

Replace and/or tighten all plugs removed or loosened

when adjusting gas pressure. Leak check the fittings

before placing the furnace into regular service. Failure to

follow this warning could result in fire, explosion, or

property damage.

For LP gases, the final manifold pressure setting shall be

10.5" W.C. with an input of no more than the nameplate

rating and no less than 93% of the nameplate rating, unless

the unit is derated for altitude.

k

Gas Valve On / Off

Toggle Switch

1st Stage (LO)

Manifold

Pressure

Adjustment

2nd Stage (HI)

Manifold

Pressure

Adjustment

White-Rodgers 36E

White-Rodgers 36G

Gas Valve On / Off

Toggle Switch

1st Stage (LO)

Manifold

Pressure

Adjustment

2nd Stage (HI)

Manifold

Pressure

Adjustment

l