SCXF-SVX01Q-EN

45

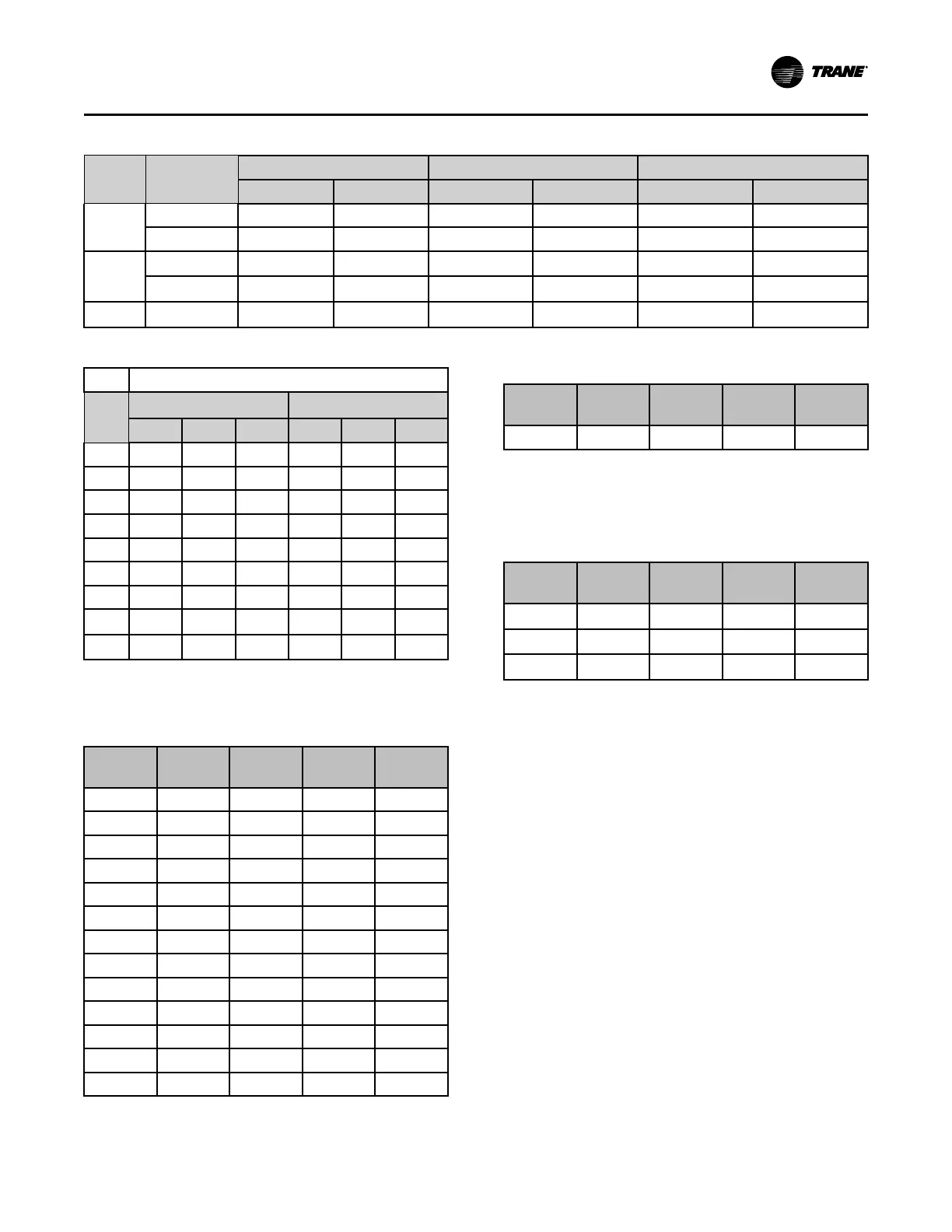

Table 27. Fan motor electrical data (continued)

HP TYPE

200V 460V 575V

FLA LRA FLA LRA FLA LRA

40

OPD 109.0 615.0 49.0 330.0 40.0 270.0

TEFC 111.0 758.0 47.4 320.0 38.0 280.0

50

ODP

N/A N/A

59.0 378.0 47.0 305.0

TEFC

N/A N/A

59.0 455.0 47.2 380.0

60 ODP

N/A N/A

71.0 464.0

N/A N/A

Table 28. VFD electrical data

VFD L.I.C.

HP

Without Bypass With Bypass

200V 460V 575V 200V 460V 575V

7.5 23.8 10.6 8.8 32.2 10.6 8.8

10 32.2 14 11.1 48.3 14 16.6

15 48.3 21 16.6 61.9 21 16.6

20 61.9 27.6 21.4 78.2 27.6 21.4

25 78.2 34 26.3 92 34 26.3

30 92 41 31.2 117 41 31.2

40 117 53 39.9 139.2 53 39.9

50 NA 64 50.6

n/a

64 50.6

60 NA 77 NA

n/a

77

n/a

Note: Values are at the maximum VFD input rating and not the

reduced motor values. L.I.C. = Line Input Current.

Table 29. Single stage electric heat electrical data

SXWF

Size

SXRF

Size Heat Kw

200V

Amps

460V

Amps

20 - 18 50 21.7

22 - 18 50 21.7

25 20 18 50 21.7

29 25 23 63.8 27.7

32 29 23 63.8 27.7

35 30 27 75 32.5

38 35 27 75 32.5

42 - 31.5 87.4 37.9

46 40 31.5 87.4 37.9

52 - 39 108.3 46.9

58 50 39 108.3 46.9

65 - 48 133.2 57.7

72 - 48 133.2 57.7

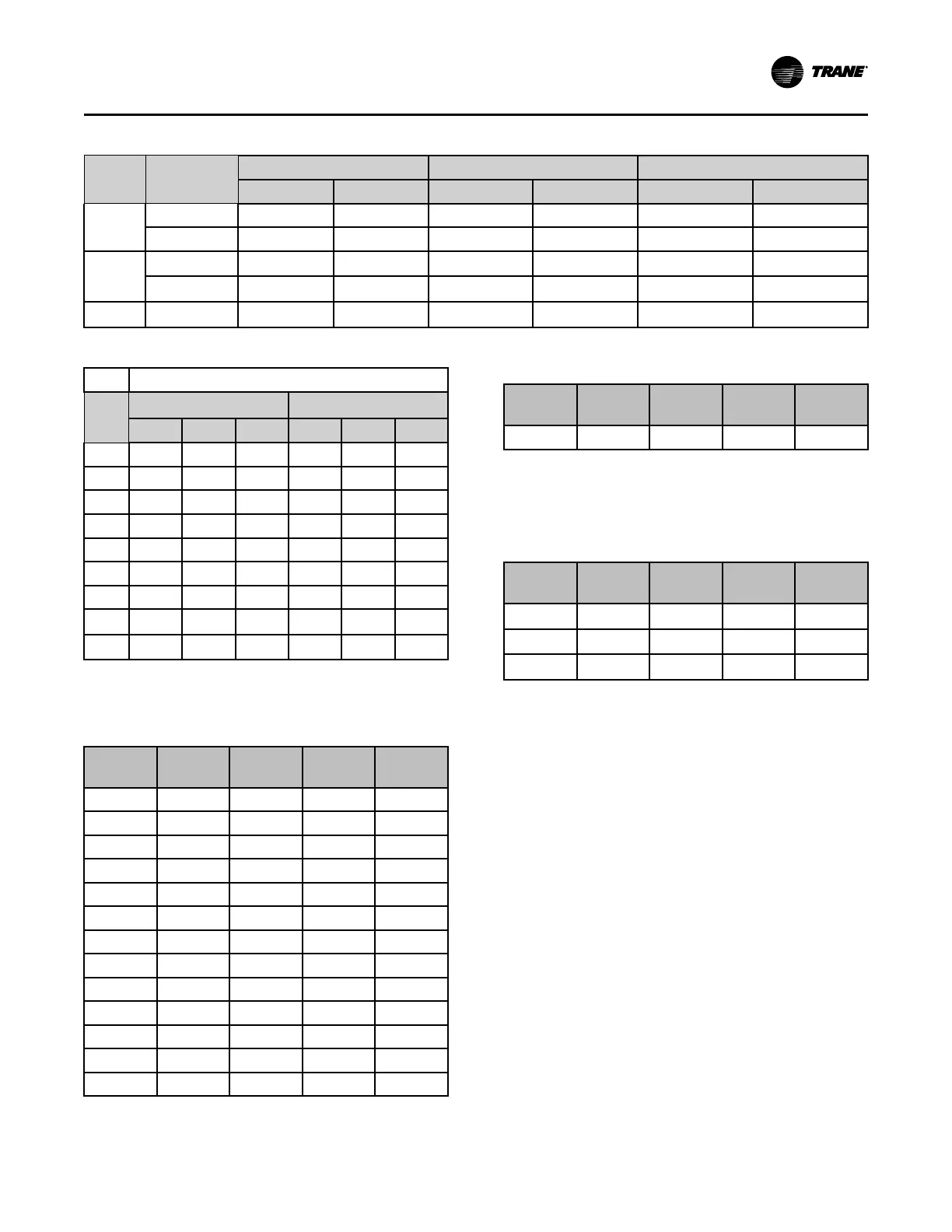

Table 29. Single stage electric heat electrical data

(continued)

SXWF

Size

SXRF

Size Heat Kw

200V

Amps

460V

Amps

80 60 48 133.2 57.7

Note: Electric heat amperage should not be considered when

determining minimum circuit ampacity. The current of the

unit in the heating mode will not exceed the current of the

unit in the cooling mode

Table 30. 2 stage electric heat electrical data

Unit Size

SCWF Heat kW

200V

Amps

460V

Amps

575V

Amps

90 76

N/A

95.39

N/A

100 76

N/A

95.39

N/A

110 76

N/A

95.39

N/A

Static Pressure Transducer

Installation (VAV units only)

Supply air static pressure controls the inverter option.

A static pressure head assembly ships separate in

control panel for field installation in the supply air duct

work. Installer is responsible for providing pneumatic

tubing.

Transducer Location

Place head assembly in an area of ductwork that will

provide an average and evenly distributed airflow

pattern. Use the following guidelines to determine an

appropriate installation location.

1. Locate static head assembly approximately 2/3 to 3/

4 the way down longest duct run, in an area

approximately 10 duct diameters downstream and

2 duct diameters upstream of major interferences,

turns, or changes in duct diameter.

2. When installing pneumatic tubing between head

assembly and transducer in control panel, do not

exceed 250ft for 1/4” OD tubing or 500ft for 3/8” OD

tubing.

IInnssttaallllaattiioonn -- EElleeccttrriiccaall

Loading...

Loading...