RLC-SVX14H-GB

92

Refrigerant Charge

If a low refrigerant charge is suspected, fi rst determine

the cause of lost refrigerant. Once the problem is

repaired follow the procedures below for evacuating and

charging the unit.

Evacuation and Dehydration

1. Disconnect ALL power before/during evacuation.

2. Connect the vacuum pump to the 5/8” fl are

connection on the bottom of the evaporator and/or

condenser.

3. To remove all of the moisture from the system and to

insure a leak free unit, pull the system down below

500 microns.

4. After the unit is evacuated, perform a standing rise

test for at least an hour. The pressure should not rise

more than 150 microns. If the pressures rises more

than 150 microns, either a leak is present or moisture

is still in the system.

Note: If oil is in the system, this test is more diffi cult. The

oil is aromatic and will give off vapors that will raise the

pressure of the system.

Refrigerant Charging

Once the system is deemed leak and moisture free,

use the 5/8” fl are connections at the bottom of the

evaporator and condenser to add refrigerant charge.

Refer to General Data Tables and Unit nameplate for

refrigerant charge information.

Refrigerant and Oil Charge Management

Proper oil and refrigerant charge is essential for proper

unit operation, unit performance, and environmental

protection. Only trained and licensed service personnel

should service the chiller.

Some symptoms of a refrigerant under-charged unit:

• Low subcooling

• Higher than normal discharge superheat

• Bubbles in EXV sight glass

• Low liquid level diagnostic

• Larger than normal evaporator approach temperatures

(leaving water temperature - saturated evaporator

temperature)

• Low evaporator refrigerant temperature limit

• Low refrigerant temperature cutout diagnostic

• Fully open expansion valve

• Possible whistling sound coming from liquid line (due

to high vapor velocity)

• High condenser + subcooler pressure drop

Service and Maintenance

Unit shut down

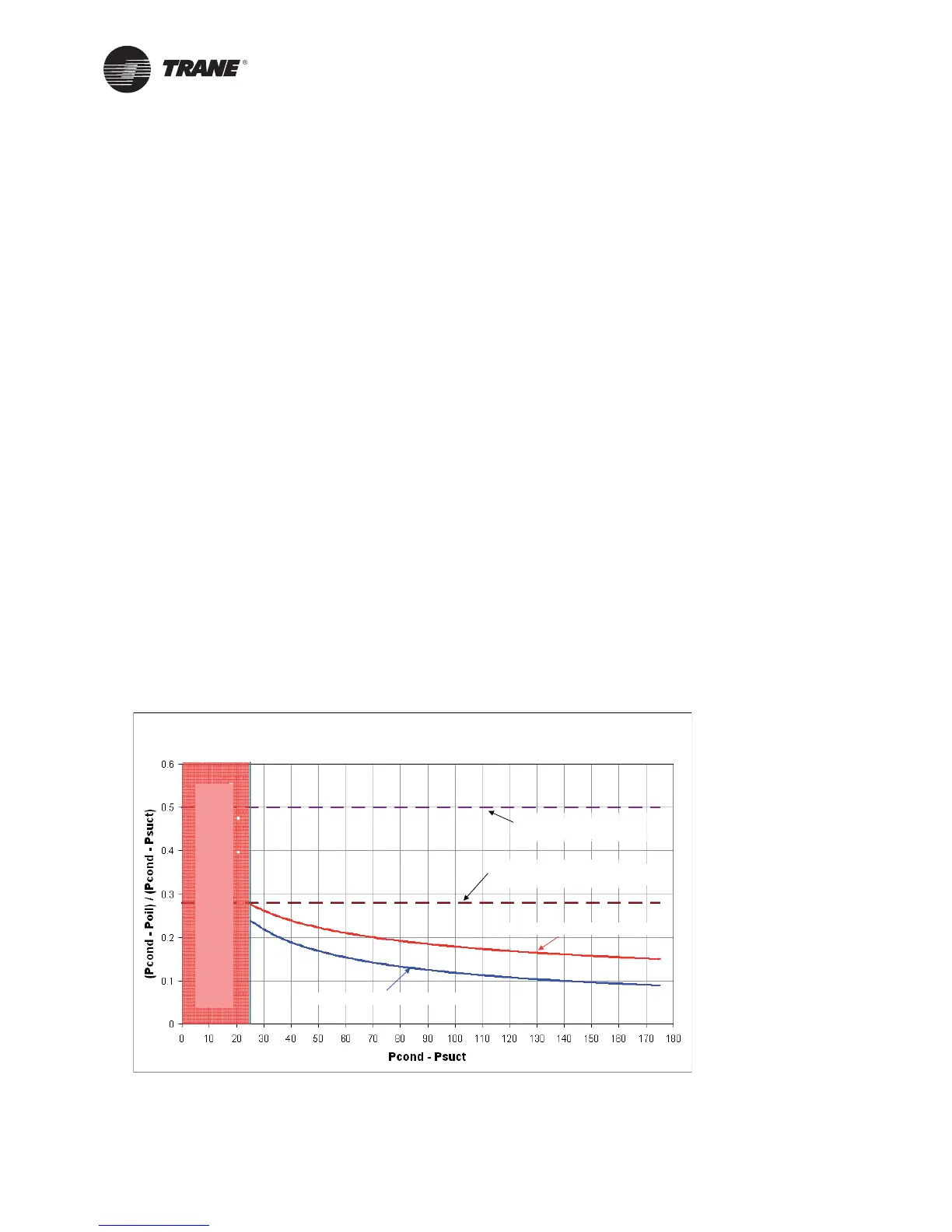

Minimum system pressure differential

= 25 psid

Clean Filter below this line

Recommend replacing filter

Start protection line for 1st

2.5 minutes of operation

Run protection line after 2.5

minutes of operation

GP2 / RTWD Clean Filter Versus Recommended Filter Replacement

Line

CH530 RTWD Oil Pressure Protection Scheme

Figure 24 - Recommended Oil Filter Replacement

Recommended replacing fi lter

Clean Filter below this line

Run protection line after 2.5

minutes of operation

Start protection line for 1st

2.5 minutes of operation

GP2 / RTWD Clean FilterVersus Recommended Filter Replacement

Line CH530 RTWD Oil Pressure Protection Scheme

Unit shut down

Minimum system pressure differential

= 25 psid

Loading...

Loading...