18-CE16D1-1B-EN

55

Setting Airflow

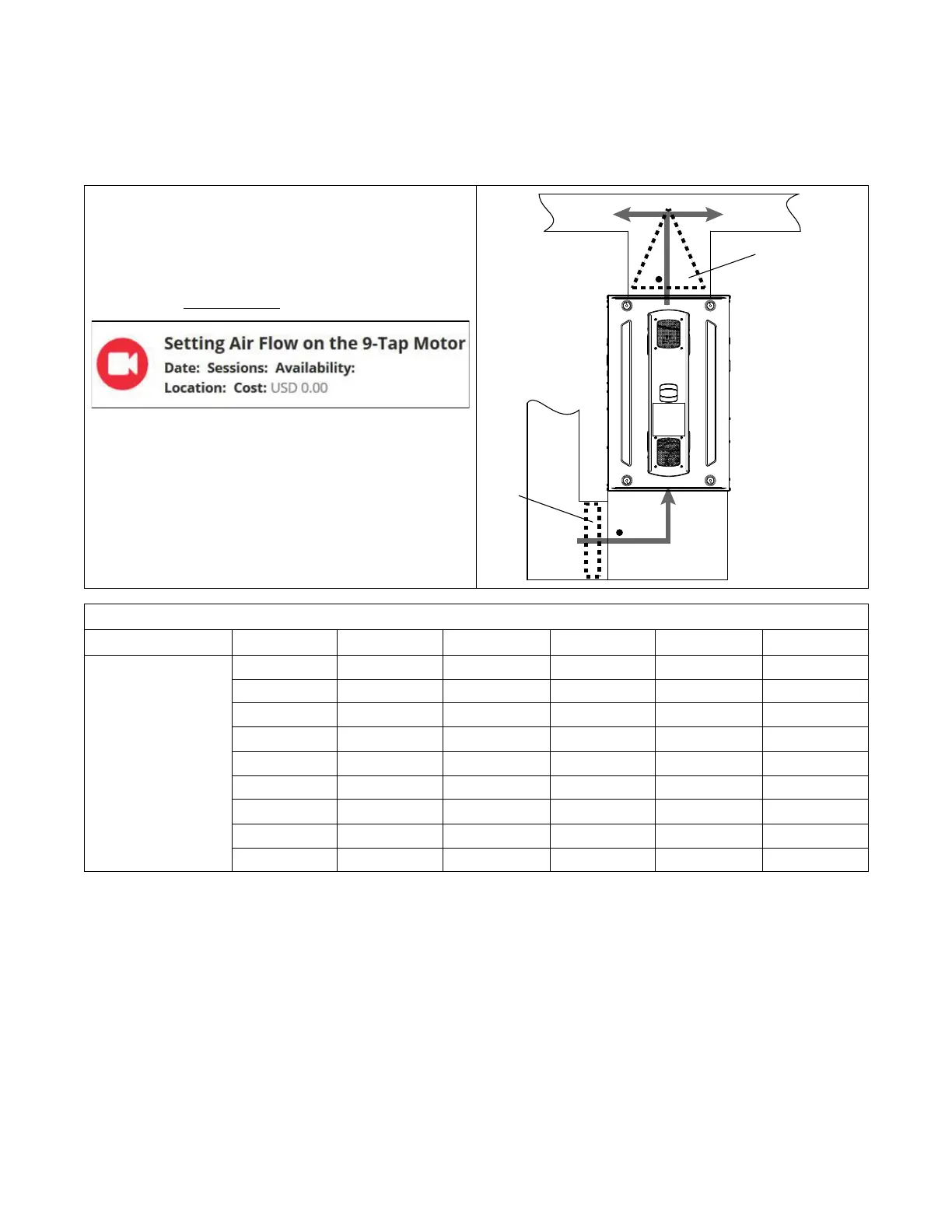

With all ductwork connected and a clean filter in place, measure the

External Static Pressure (ESP) of the unit in locations below. Use the

appropriate airflow table for the furnace and outdoor unit installed.

Note: Airflow tables are located in the Service Facts literature.

Measurements must be made prior to the evaporator coil, if equipped,

and after the filter.

Note: Check out fieldtechhelp.com to watch a short video.

Evaporato

r

Coil

Clean

Filter

Furnace Airflow (CFM) Vs. External Static Pressure (in. W.C.)

Model

Tap

0.1 0.3 0.5 0.7 0.9

S8B1B080M4PS

S8X1B080M4PS

S8X2B080M4PS

1 633 297 — — —

2 957 800 719 428 213

3 1220 1080 940 800 660

4 1403 1298 1192

1087

(a)

981

5 1524 1428 1336 1248 1164

6 1684 1574 1544 1401 1337

7 1700 1625 1551

1476

(b)

1401

(c)

8 1858 1790 1723 1656 1589

9 1967 1898 1829 1760 1691

This is an Example Airflow Table only. See Service Facts for complete Airflow data.

(a)

Exapmple 1, 2

(b)

Example 1

(c)

Example 2

Example 1: S8X2B080M4PS (Default Tap 7)

Cooling / HP

• 3 Ton Single Stage Outdoor

• Total ESP = 0.7” W.C.

• Required Airflow = 1050 cfm (3T x 350 cfm/ton)

• New Tap Number = Tap 4

Example 2: S8X2B080M4PS (Default Tap 3 & 7)

• 4 Ton Two Stage Outdoor

• Total 2

nd

Stage ESP = 0.9” W.C.

• Total 1

st

Stage ESP = 0.6” W.C.

• Required 2

nd

Stage Airflow = 1400 cfm (4T x 350

cfm/ton)

• Required 1

st

Stage Airflow = 1050 cfm (2

nd

stage

airflow x .75)

• New 2

nd

Stage Tap Number = Tap 7 (no change)

• New 1

st

Stage Tap Number = Tap 4

Loading...

Loading...