18-CE04D1-1B-EN

19

The furnace is shipped standard for left side installation of gas piping.

A cutout with plug is provided on the right side for an alternate gas

piping arrangement.

The installation of piping shall be in accordance with piping codes and

the regulations of the local gas company. Pipe joint compound must be

resistant to the chemical reaction with liquefied petroleum gases.

Important: If local codes allow the use of flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously serviced another gas

appliance.

Refer to the piping table for delivery sizes. Connect gas supply to the

unit, using a ground joint union and a manual shut-off valve. National

codes require a condensation drip leg to be installed ahead of the gas

valve.

The furnace and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5 kPa).

The furnace must be isolated from the gas supply piping by closing its

individual manual shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

Note: Maximum pressure to the gas valve for natural gas is 13.8" W.

C. Minimum pressure is 5.0" W.C. Maximum pressure to the

gas valve for propane is 13.8" W.C. Minimum pressure is 11.0"

W.C.

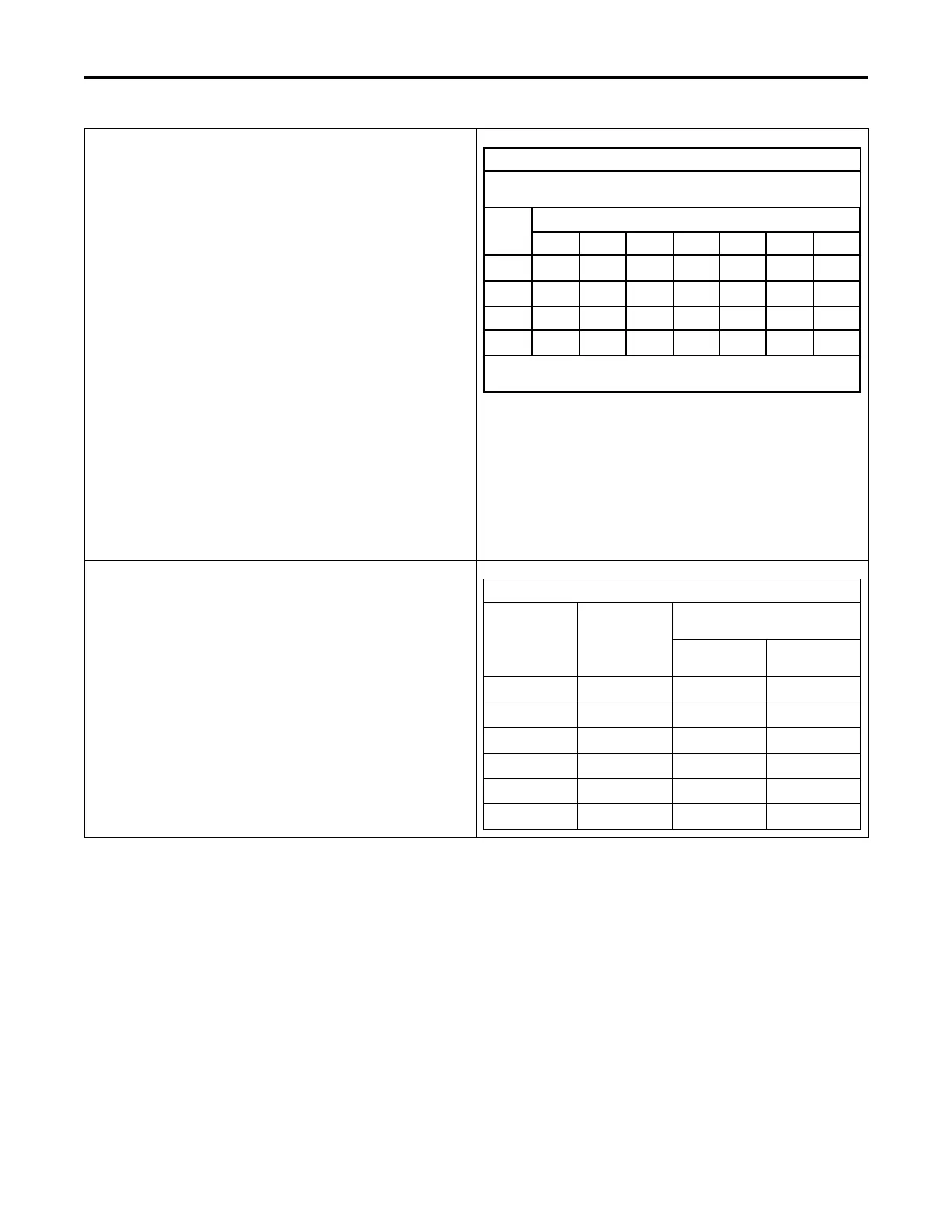

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

LENGTH OF PIPE

10 20 30 40 50 60 70

1/2 131 90 72 62 55 50 46

3/4 273 188 151 129 114 104 95

1 514 353 284 243 215 195 179

1–1/4 1060 726 583 499 442 400 368

This table is based on Pressure Drop of 0.3 inch W.C. and 0.6 SP.

GR. Gas

All gas fittings must be checked for leaks using a soapy solution before

lighting the furnace. DO NOT CHECK WITH AN OPEN FLAME!

For propane conversions, the S8X1A026 will require LP kit

BAYLPSS410A conversion kit with stainless steel burners. For propane

conversions on all other S-Series Furnaces, use BAYLPSS400B

conversion kit with stainless steel burners.

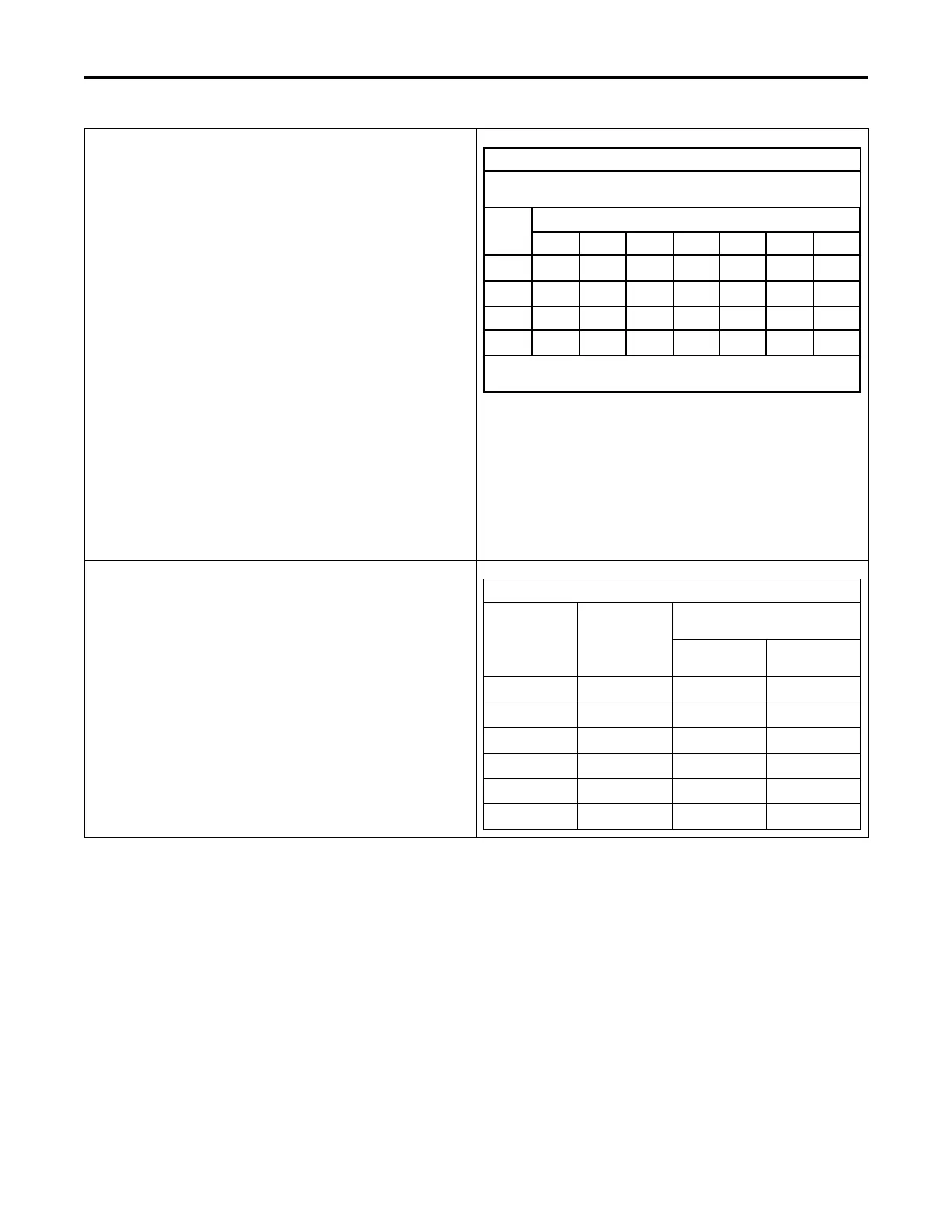

ORIFICE SIZES

INPUT

RATING

BTUH

NUMBER OF

BURNERS

MAIN BURNER ORIFICE

DRILL SIZE

NAT. GAS PROPANE

GAS

26,000 2 51 59

40,000 2 45 56

60,000 3 45 56

80,000 4 45 56

100,000 5 45 56

120,000 6 45 56

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Loading...

Loading...