58

18-CE04D1-1B-EN

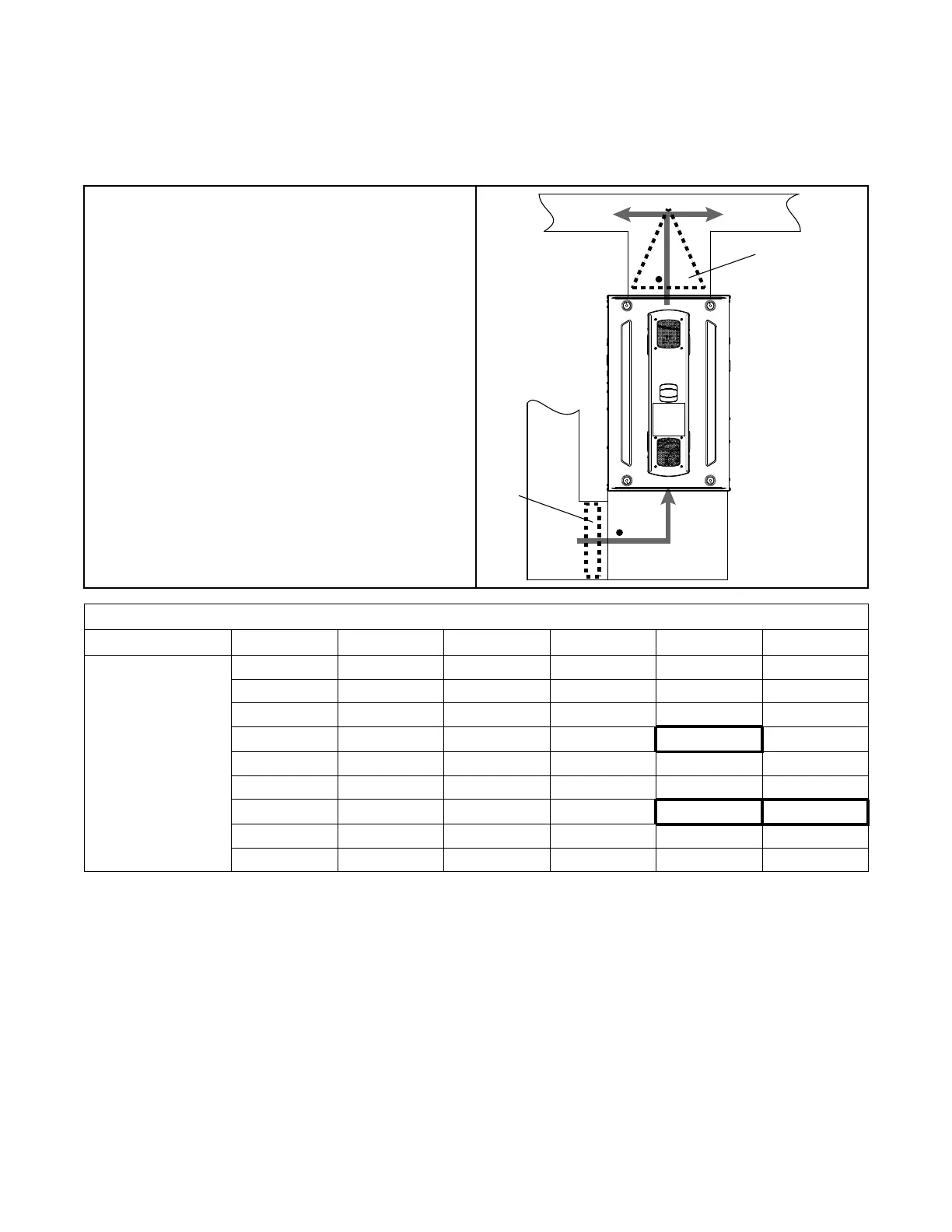

Setting Airflow

With all ductwork connected and a clean filter in place, measure the

External Static Pressure (ESP) of the unit in locations below. Use the

appropriate airflow table for the furnace and outdoor unit installed.

Measurements must be made prior to the evaporator coil, if equipped,

and after the filter.

Evaporato

r

Coil

Clean

Filter

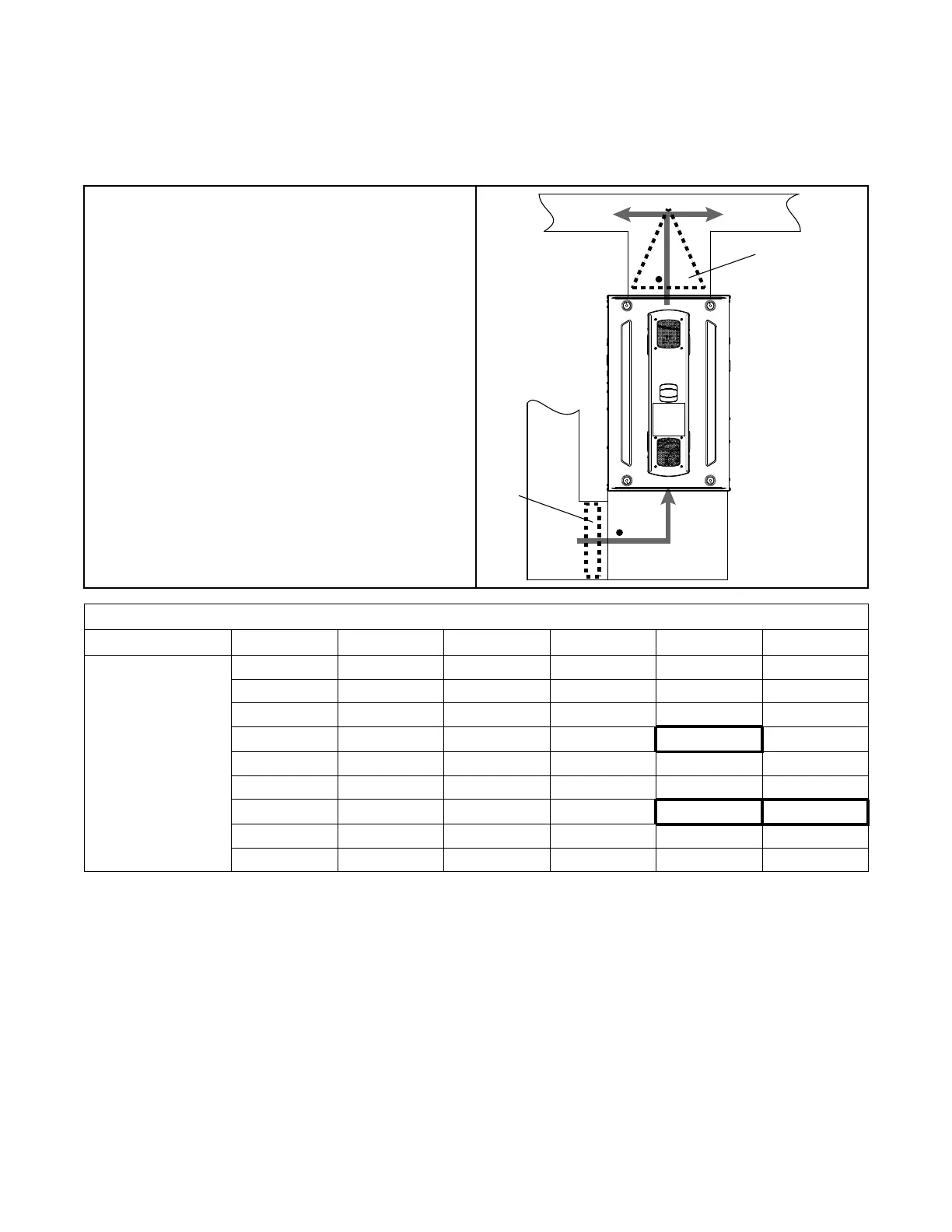

Furnace Airflow (CFM) Vs. External Static Pressure (in. W.C.)

Model

Tap

0.1 0.3 0.5 0.7 0.9

S8X1B080M4PSAA

S8X2B080M4PSAA

1 633 297 — — —

2 957 800 719 428 213

3 1220 1080 940 800 660

4 1403 1298 1192

1087

(a)

981

5 1524 1428 1336 1248 1164

6 1684 1574 1544 1401 1337

7 1700 1625 1551

1476

(b)

1401

(c)

8 1858 1790 1723 1656 1589

9 1967 1898 1829 1760 1691

(a)

Exapmple 1, 2

(b)

Example 1

(c)

Example 2

Example 1: S8X2B080M4PSAAA (Default Tap 7)

Cooling / HP

• 3 Ton Single Stage Outdoor

• Total ESP = 0.7” W.C.

• Required Airflow = 1050 cfm (3T x 350 cfm/ton)

• New Tap Number = Tap 4

Example 2: S8X2B080M4PSAA (Default Tap 3 & 7)

• 4 Ton Two Stage Outdoor

• Total 2

nd

Stage ESP = 0.9” W.C.

• Total 1

st

Stage ESP = 0.6” W.C.

• Required 2

nd

Stage Airflow = 1400 cfm (4T x 350

cfm/ton)

• Required 1

st

Stage Airflow = 1050 cfm (2

nd

stage

airflow x .75)

• New 2

nd

Stage Tap Number = Tap 7 (no change)

• New 1

st

Stage Tap Number = Tap 4

Loading...

Loading...