8 18-CD26D1-10

Installer’s Guide

The bottom panel of the upflow furnace must be removed for

bottom return air.

Remove the filter and lay the furnace on its back. Remove the

two 5/16" hex screws securing the bottom front channel to the

cabinet. Lower the front edge of the bottom front channel and

pull forward to remove the channel. The bottom return air

panel will now easily slide out of the cabinet. Reinstall the

bottom front channel and filter for upflow bottom return

installations.

UPFLOW INSTALLATION

Standoffs and screws (See Figure 4) are included with the

cased coils for attachment to the Furnace. There are clear-

ance alignment holes near the bottom of the coil wrapper.

Drill screws are used to engage the Furnace top flanges. The

standoff is inserted into the cabinet alignment hole. The drill

screws are inserted through the standoffs then screwed into

the Furnace flange. The coil is always placed downstream of

the Furnace airflow. The above instructions apply only if the

coil is on top of an upflow Furnace

DOWNFLOW INSTALLATION

HORIZONTAL INSTALLATION

The coil and Furnace must be fully supported when used in

the horizontal position. It is always recommended that an

auxiliary drain pan be installed under a horizontally in-

stalled evaporator coil or 90% Gas Furnace. Connect the

auxiliary drain line to a separate drain line (no trap is needed

in this line).

Three brackets (with screws) are included with downflow

furnaces for installtion to stabilize and secure the 2/4TXC

cased coil in the horizontal position. See Figure 8.

The cased coil is secured to the Furnace. The brackets mount

using the rear screws on the coil case. Use the screws provided

to secure the bracket to the Furnace. The remaining bracket

is placed as close to horizontal center as possible between the

coil and the Furnace, converted to horizontal, aligns and

attaches to the TXC coil.

The Furnace and the cased coil must be properly supported.

The Furnace may be installed in an attic or crawl space in the

horizontal position by placing the Furnace on the left side (as

viewed from the front in the vertical position). The horizontal

Furnace installation in an attic should be on a service

platform large enough to allow for proper clearances on all

sides and service access to the front of the Furnace (See

Figure 6 & Table 1). Line contact is only permissible between

lines formed by intersections of the top and two sides of the

furnace casing and building joists, studs, or framing.

The Furnace may be placed horizontally in a crawl space on a

pad or other noncombustible material which will raise the

unit for sufficient protection from moisture.

The Furnace must be supported at both ends and the

middle when installed horizontally. The Furnace must

also be elevated approximately 4-6 inches to allow

clearance for the condensate drain to exit the cabinet in

the horizontal position.

WARNING

!

FIRE HAZARD. DO NOT INSTALL THE FURNACE DIRECTLY

ON CARPETING, TILE OR OTHER COMBUSTIBLE MATE-

RIAL OTHER THAN WOOD FLOORING. FOR VERTICAL

DOWNFLOW APPLICATION, SUBBASE (BAYBASE205)

MUST BE USED BETWEEN THE FURNACE AND COMBUS-

TIBLE FLOORING. WHEN THE DOWNFLOW FURNACE IS

INSTALLED VERTICALLY WITH A CASED COIL, A SUB-

BASE IS NOT REQUIRED.

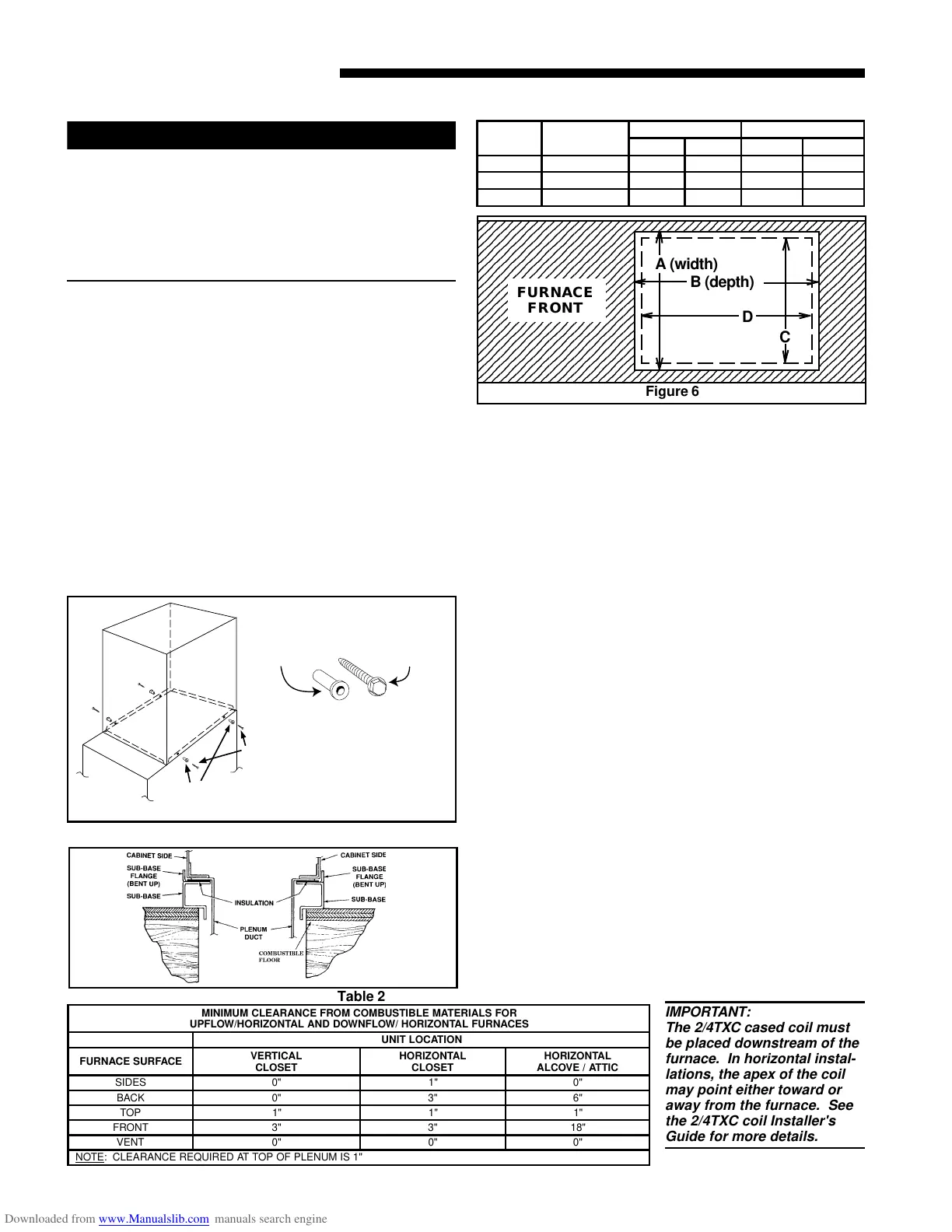

Table 1 Required floor opening: (DOWNFLOW)

CABINET

WIDTH

RETURN

DUCT WIDTH

FLOOR OPENING PLENUM OPENING

"A" "B" "C" "D"

17-1/2" 16-1/4" 16-5/8" 20-1/8" 15-5/8" 19-3/8"

21" 19-3/4" 20-1/8" 20-1/8" 19-1/8" 19-3/8"

24-1/2" 23-1/4" 23-5/8" 20-1/8" 22-5/8" 19-3/8"

INSTALLATION INSTRUCTIONS

Figure 5

UPFLOW

FURNACE

CASED

COIL

SCREW

(BOTH SIDES

STANDOFFS

(BOTH SIDES)

TANDOFFS (4)

DRILL SCREWS (

FOR VERTICAL

Figure 4

123456789012345678901234567890121234567890123456

1

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

2345678901234567890123456789012123456789012345

6

123456789012345678901234567890121234567890123456

FURNACE

FRONT

A (width)

B (depth)

C

D

Figure 6

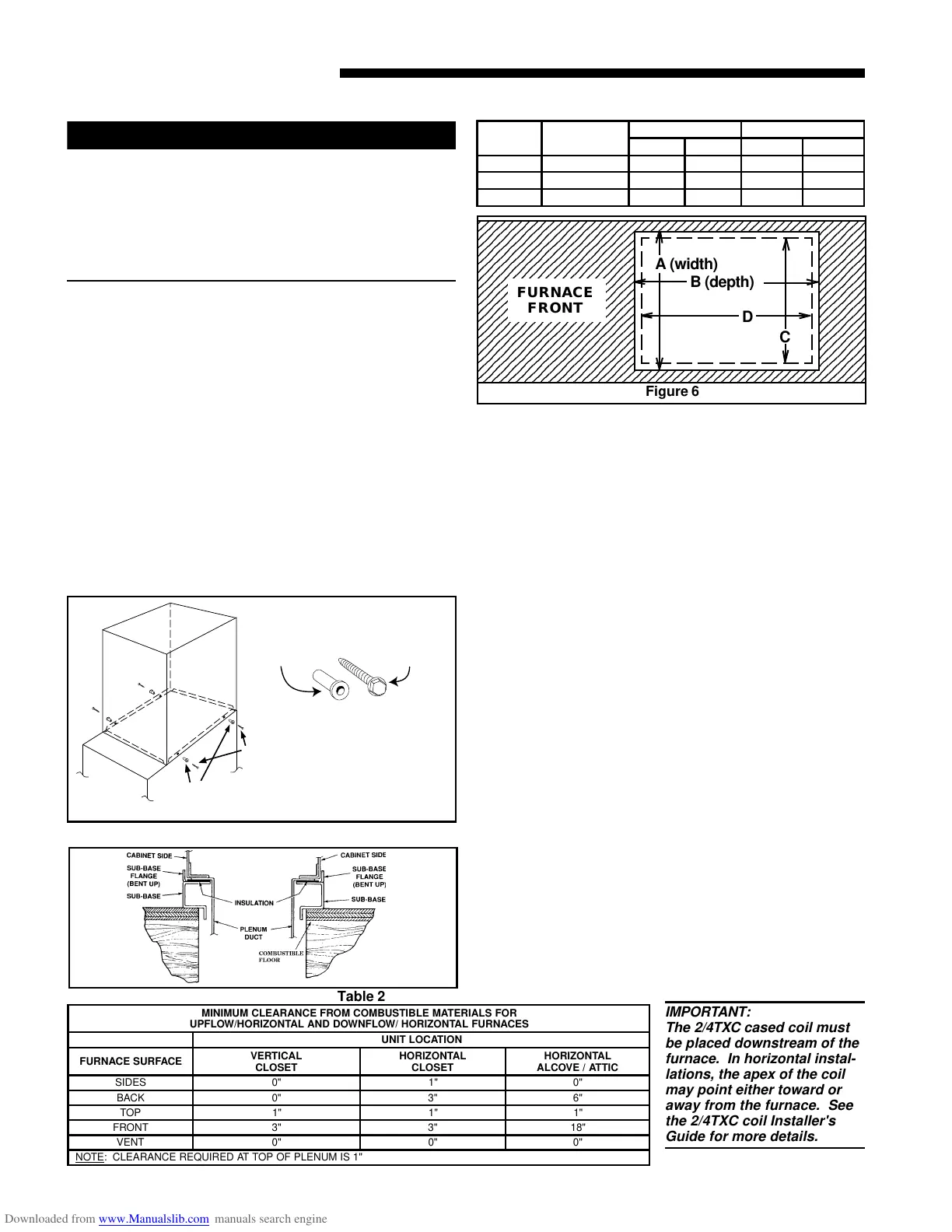

MINIMUM CLEARANCE FROM COMBUSTIBLE MATERIALS FOR

UPFLOW/HORIZONTAL AND DOWNFLOW/ HORIZONTAL FURNACES

UNIT LOCATION

FURNACE SURFACE

VERTICAL

CLOSET

HORIZONTAL

CLOSET

HORIZONTAL

ALCOVE / ATTIC

SIDES 0" 1" 0"

BACK 0" 3" 6"

TOP 1" 1" 1"

FRONT 3" 3" 18"

VENT 0" 0" 0"

NOTE

: CLEARANCE REQUIRED AT TOP OF PLENUM IS 1"

Table 2

IMPORTANT:

The 2/4TXC cased coil must

be placed downstream of the

furnace. In horizontal instal-

lations, the apex of the coil

may point either toward or

away from the furnace. See

the 2/4TXC coil Installer's

Guide for more details.

Loading...

Loading...