18-CD26D1-10 11

Installer’s Guide

Carbon monoxide, fire or smoke can cause serious bodily

injury, death, and/or property damage.

A variety of potential sources of carbon monoxide can be found

in a building or dwelling such as gas-fired clothes dryers, gas

cooking stoves, water heaters, furnaces and fireplaces. The

U.S. Consumer Product Safety Commission recommends

that users of gas-burning appliances install carbon monoxide

detectors as well as fire and smoke detectors per the manu-

factures installation instructions to help alert dwelling

occupants of the presence of fire, smoke or unsafe levels of

carbon monoxide. These devices should be listed by Under-

writers Laboratories, Inc. Standards for Single and Multiple

Station Carbon Monoxide Alarms, UL 2034 or CSA Interna-

tional Standard, Residential Carbon Monoxide Alarming

Devices, CSA 6.19.

NOTE: The manufacturer of your Furnace DOES NOT test

any detectors and makes no representations regarding any

brand or type of detector.

All return air duct systems should provide for installation of

return air filters.

PREPARATION FOR UPFLOW BOTTOM AND SIDE RETURN

AIR FILTER INSTALLATION

All return air duct systems should provide for installation of

return air filters.

1. Determine the appropriate position to set the furnace in

order to existing supply and return ductwork.

2. The return air filter and rack are shipped in either the

bottom or side location. Remove the filter and filter rack

by first turning the two latches on the blower door and

tilting the door forward to remove. Remove the filter by

sliding it out of the rack. Compress the spring loaded

filter rack to disengage the retaining pins/screws from

the furnace sides and slide the filter rack out.

The filter rails are spring loaded for automatic adjust-

ment to allow standard size, locally obtainable replace-

ment filters. The filter rack itself slides to adjust to the

required width needed for bottom or side return (See

Figure 15).

3. For upflow side return installations, remove the insulation

around the opening in the blower compartment.

4. The side panels of the upflow furnace include locating

notches that are used as guides for cutting an opening for

return air, refer to Figure 13 and the outline drawing on

page 6 for duct connection dimensions for various

furnaces.

5. If a 3/4" flange is to be used for attaching the air inlet

duct, add to cut where indicated by dotted lines in

Figure 13. Cut corners diagonally and bend outward to

form flange.

6. If flanges are not required, and a filter frame is installed,

cut between locating notches (See Figure 13).

7. The bottom panel of the upflow furnace must be removed

for bottom return air. After removing the filter and filter

rack, lay the furnace on its back. Remove the two 5/16"

hex screws securing the front of the bottom channel to the

cabinet. Rotate the channel downward (or remove by

lowering the front edge of the channel and pulling

forward).

Return Air Filters

TYPICAL UPFLOW RETURN AIR FILTER INSTALLATIONS

Filters are factory supplied for these furnaces. These fur-

naces require high velocity type air filters. The filters may be

installed within the furnace blower compartment for UP-

FLOW furnaces in either a BOTTOM or SIDE (left side or

right side) return air inlet. Some filters may need to be

trimmed for side or bottom filter use.

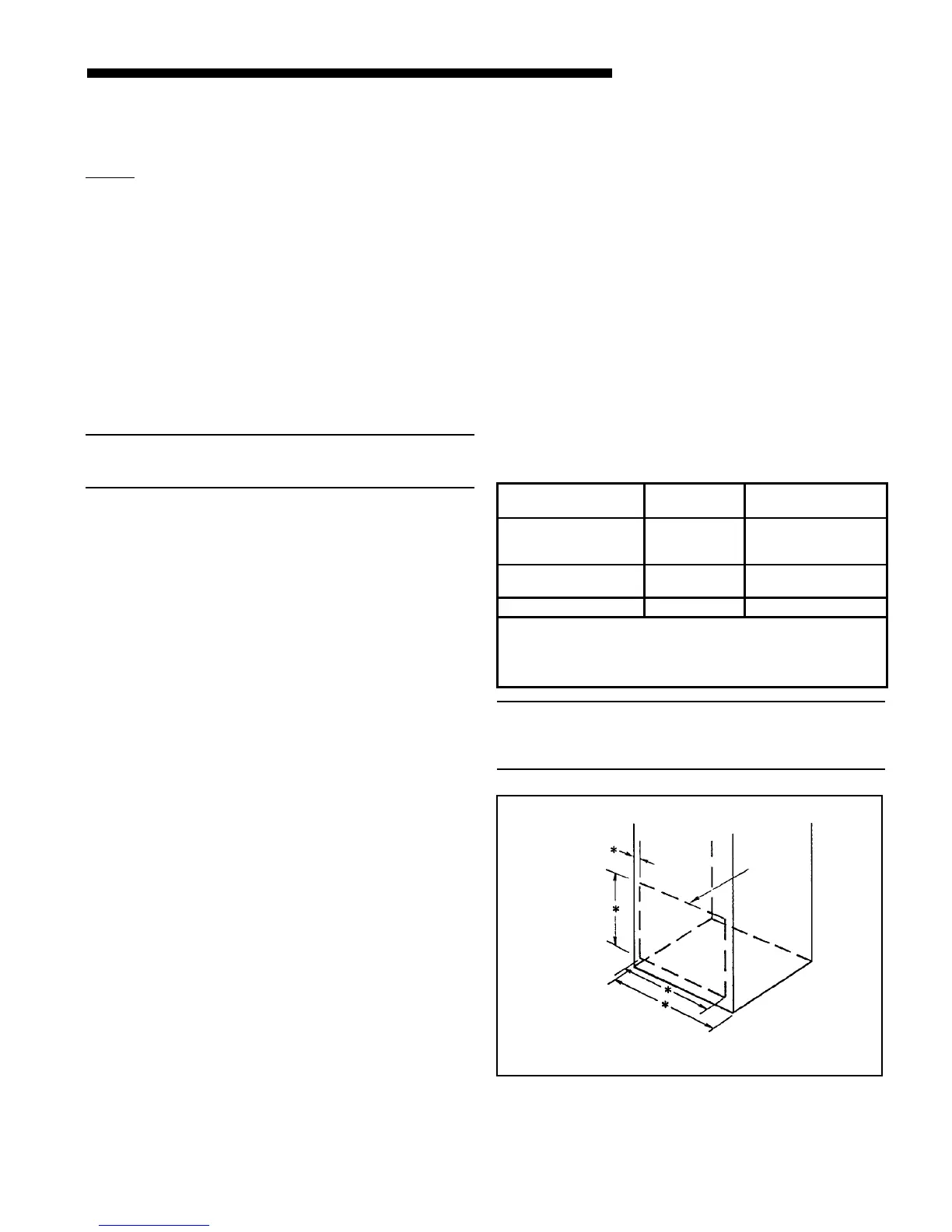

Table 5

MODELS

NUMBERS

CABINET

WIDTH

FILTER

QTY & SIZE

*UH2B060A9V3VA

*UH2B080A9V3VA

*UH2B080A9V4VA

17-1/2" 1 - 17" X 25" X 1"

*UH2C100A9V4VA

*UH2C100A9V5VA

21" 1 - 20" X 25" X 1"

*UH2D120A9V5VA 24-1/2" 1 - 24" X 25 X 1"

*First letter may be "A" or "T"

**NOTE: For upflow 5 ton airflow models where the airflow

requirement exceeds 1800 CFM - Modles will require return air

openings and filters on: (1) both sides, or (2) one side and the

bottom, or (3) just on the bottom

NOTE: For upflow 5 ton airflow models where the airflow

requirement exceeds 1800 CFM - Models will require return

air openings and filters on: (1) both sides, or (2) one side and

the bottom, or (3) just the bottom.

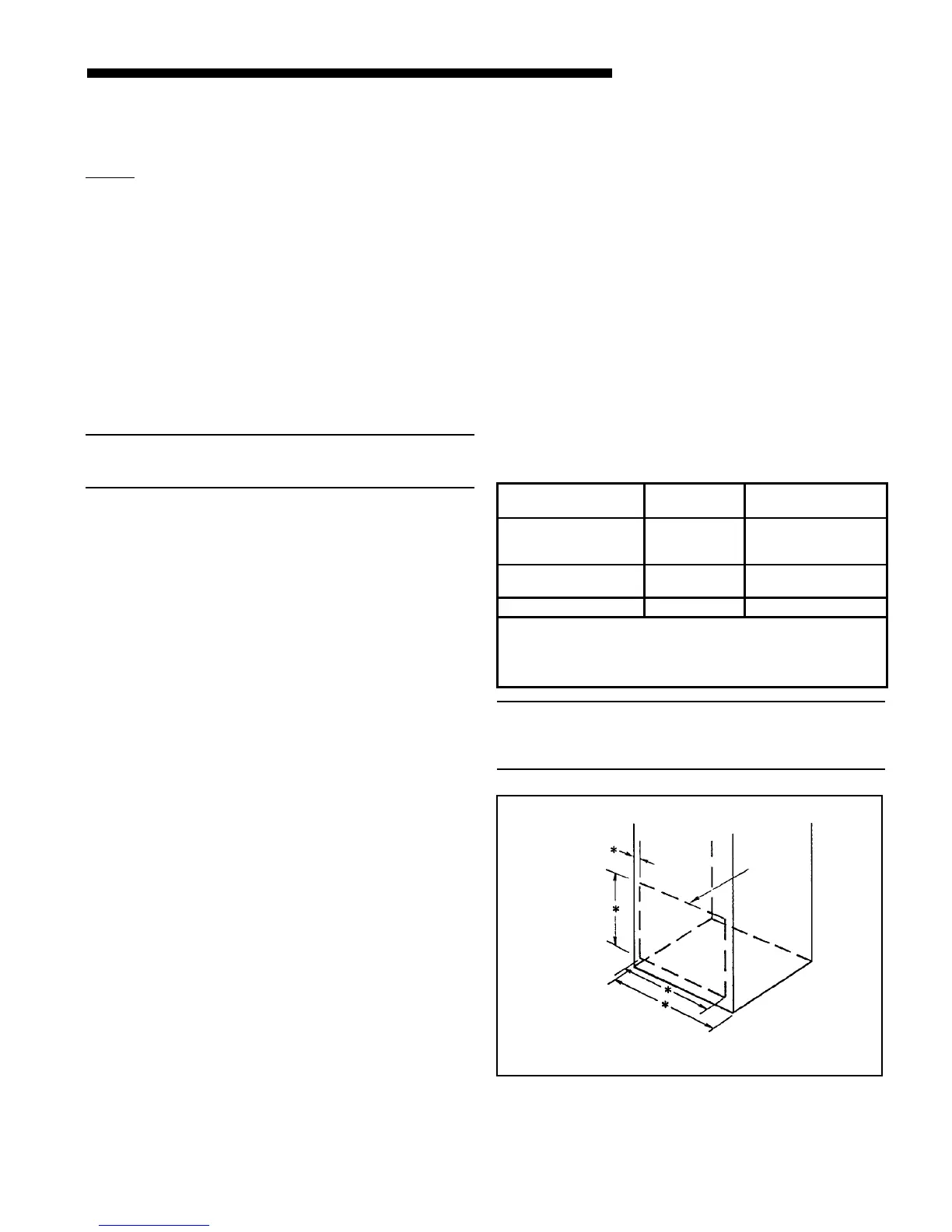

UPFLOW FURNACE ONLY

*

SEE OUTLINE DRAWING

FRONT

of Furnace

LOCATING

NOTCHES

PROVIDED FOR

SIDE RETURN

CUTOUT

Figure 13

Where there is no complete return duct system, the

return connection must be run full size from the Fur-

nace to a location outside the utility room, basement,

attic, or crawl space.

Do Not install return air through the back of the Furnace

cabinet.

Slide the bottom return air panel out of the cabinet.

Rotate the front channel to its original position and

reinstall the two 5/16” screws.

8. The horizontal installation of the upflow furnace

requires an external filter section. Do NOT use the

bottom return filter within the furnace. Filter kits

are available for horizontal applications.

9. Connect duct work to furnace. See Outline Drawing for

supply and return duct size and location. Flexible duct

connectors are recommended to connect both supply and

return air ducts to the furnace. If only the front of the

furnace is accessible, it is recommended that both supply

and return air plenums are removable.

Loading...

Loading...