26

VAV-SVX08R-EN

Chilled Water Sensible Cooling

Terminal Units Moisture Sensor

Installation

In most applications, the water supplied to this local

cooling coil is controlled to a temperature above the

dew point in the zone. This avoids moisture in the air

from condensing on the coil, so it operates dry and

provides only sensible cooling. All dehumidification

must then be provided by the dedicated outdoor-air

unit. Trane chilled water sensible cooling terminal units

are built with a drip pan located beneath and above the

cooling coil, with a moisture sensor installed, to detect

and prevent any moisture from getting on the ceiling

beneath the units or into the occupied space below.

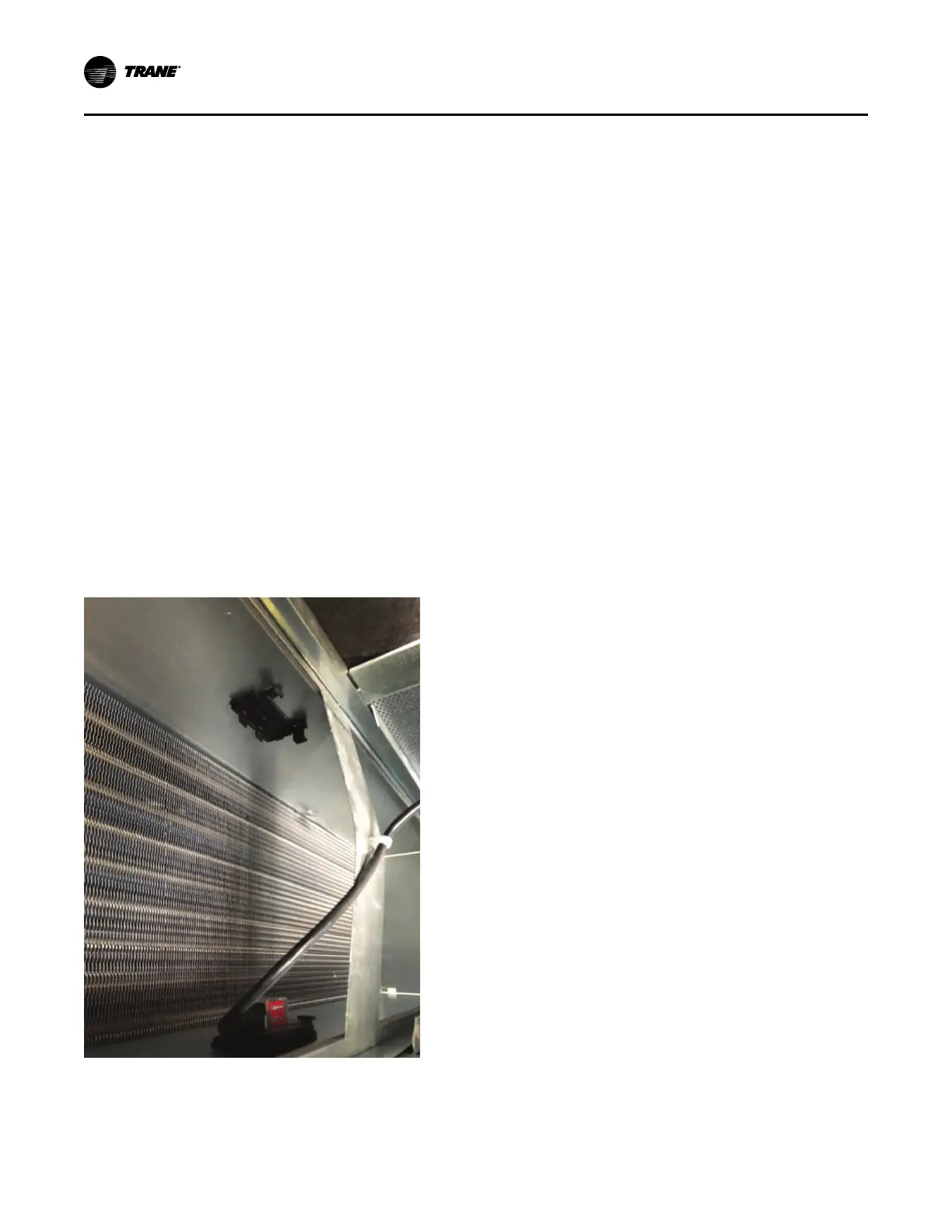

Sensible cooling units are designed so that the unit can

be flipped 180 degrees for right and left hand

orientation. They are configured as left hand from the

factory with a moisture sensor installed to a bracket on

the bottom of the drip pan. If installed as a right hand

unit the moisture sensor will need to be moved to the

bracket provided (shown in the following figure) so that

the moisture sensor is on the bottom of the unit for

proper moisture detection.

Figure 19. Moisture sensor installation and additional

bracket shown in cooling coil drip pan

Unit Accessibility

• Single-duct and dual-duct units provided with hot

water reheat have an access panel located on the

side of the water coil. All other single-duct and dual-

duct units are provided without access, as all

functioning components are external to the unit.

• Fan-powered terminals are provided with a sliding

side access.

• Low-height terminal units have a removable

bottom panel.

Clearances

For proper service, it is recommended that at least 3

inches” of side clearance be provided to service and

access single-duct and dual-duct terminals units.

• Fan-powered VAV units have a plenum inlet that

must be clear of obstructions. Allow at least 36

inches of clearance in front of the side access and

plenum opening.

• Low-height fan-powered terminals require the

same plenum clearance requirement that applies to

the standard fan-powered units. However the

access to the internal components is located on the

bottom of the unit.

• Fan-powered VAV units with Suppressor attenuator

requires at least 4.5 inches (6 inches preferred)

clearance above the plenum opening.

• Fan-powered VAV units with Thinline Suppressor

attenuator requires at least 4.5 inches (6 inches

preferred) clearance at plenum openings.

It is also recommended that 6 inches of clearance be

provided to the top and bottom of all the units.

NNoottee:: The minimum clearance for controls and heater

controls should be 36 inches for all models

except units with 575-volt electric heaters, which

require 48 inches of clearance. NEC

™

and/or

local codes override all clearance requirements.

Mounting Actuator

IImmppoorrttaanntt:: When installing or replacing the actuator

tighten the actuator set screw per the

manufacturer’s instructions. Failure to

follow the manufacturer’s specifications

may result in unit malfunction.

Trane offers a factory-mounted actuator with a 90-

second drive time. The actuator drives 1° per second. A

field-installed actuator may be used if desired. The

actuator shaft has a 0.5 inch diameter and is designed

to travel clockwise to close the damper and counter-

clockwise to open the damper. There is an indicator on

the end of the actuator shaft that can be used to

determine the position of the damper.

Stand-alone Units

Stand-alone UCM 4.2

When there is no communication to the UCM control

and the unit is in the stand-alone mode the control

UUnniitt IInnssttaallllaattiioonn

Loading...

Loading...