19

Installation info

CALCULATION OF PRESSURE LOSSES

FOR DISCHARGE AND SUCTION DUCTS

Bear in mind the following parameters when

calculating pressure losses:

- for each metre of duct with Ø 80 (both

suction and discharge) the pressure loss

is 2 Pa;

- for each 90° Ø 80 (R=D) bend with long

radius, the pressure loss is 2 Pa;

- for each 90° Ø 80 (R=½ D) bend with

short radius, the pressure loss is 6 Pa in

suction and 8 Pa in discharge;

- for the Ø 80 L = 0.5 m horizontal air inlet

terminal, the pressure loss is 3 Pa;

- for the Ø 80 L = 0.6 m horizontal

discharge end section, the pressure loss

is 5 Pa;

- 2 short radius 90° Ø 80 curves + 1

adapter Ø 80, the pressure loss is 14

Pa.

fig. 20

fig. 19

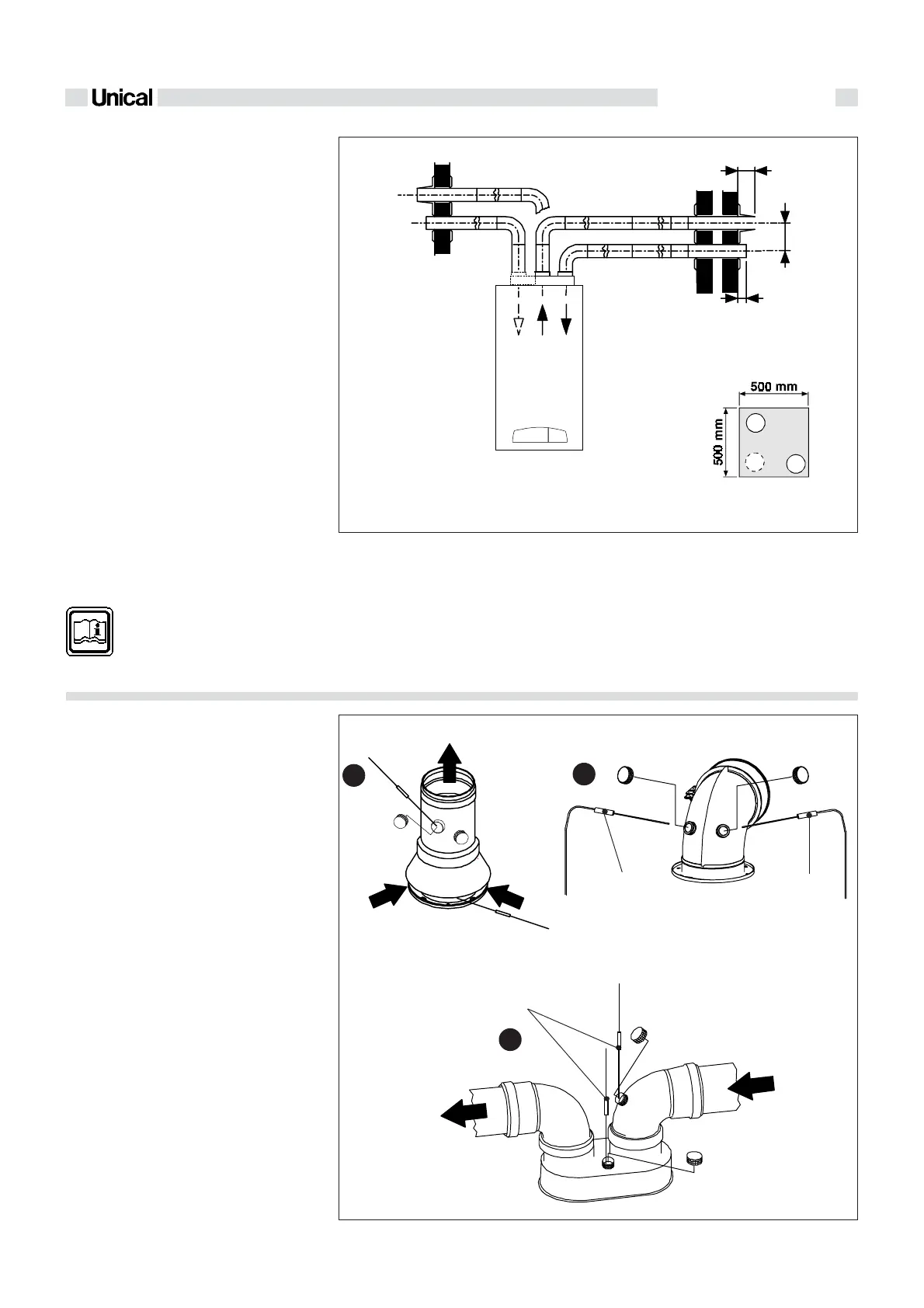

2.2.11- MEASUREMENTS OF

COMBUSTION EFFICIENCY

Ducts Ø 80 type B22 (C)

Coaxial ducts (A)

Dual ducts Ø 80 (B)

To determine combustion efficiency the fol-

lowing measurements must be made:

- the combustion air temperature measured

in hole 2 (see fig. 20).

- the flue gas temperature and CO

2

% mea-

sured in hole 1 (see fig. 20).

Make these measurements with the boiler

running in a steady state condition.

135

45

C

Sonda

analizzatore

2

1

250 min.

Sonda

analizzatore

NB: These values refer to di-

scharges through original UNI-

CAL non-flexible and smooth

ducts.

Example of check using wide radius

bends:

- 2 Ø 80 long radius 90° bends + 1 adapter

Ø 80

(14 Pa)

- (TFS 28) 17 mt duct Ø 80 x 2 =

(34 Pa)

- (TFS 24) 12 mt duct Ø 80 x 2 =

(24 Pa)

- 2 90° Ø 80 long radius bends x 4 =

8 Pa

- horizontal Ø 80 air inlet terminal =

3 Pa

- horizontal Ø 80 terminal =

5 Pa

Tot. pressure loss (TFS 28) = 60 Pa

Tot. pressure loss (TFS 24) = 50 Pa

1

2

Sonda

analizzatore

Sonda

analizzatore

Fumi

Aria

A

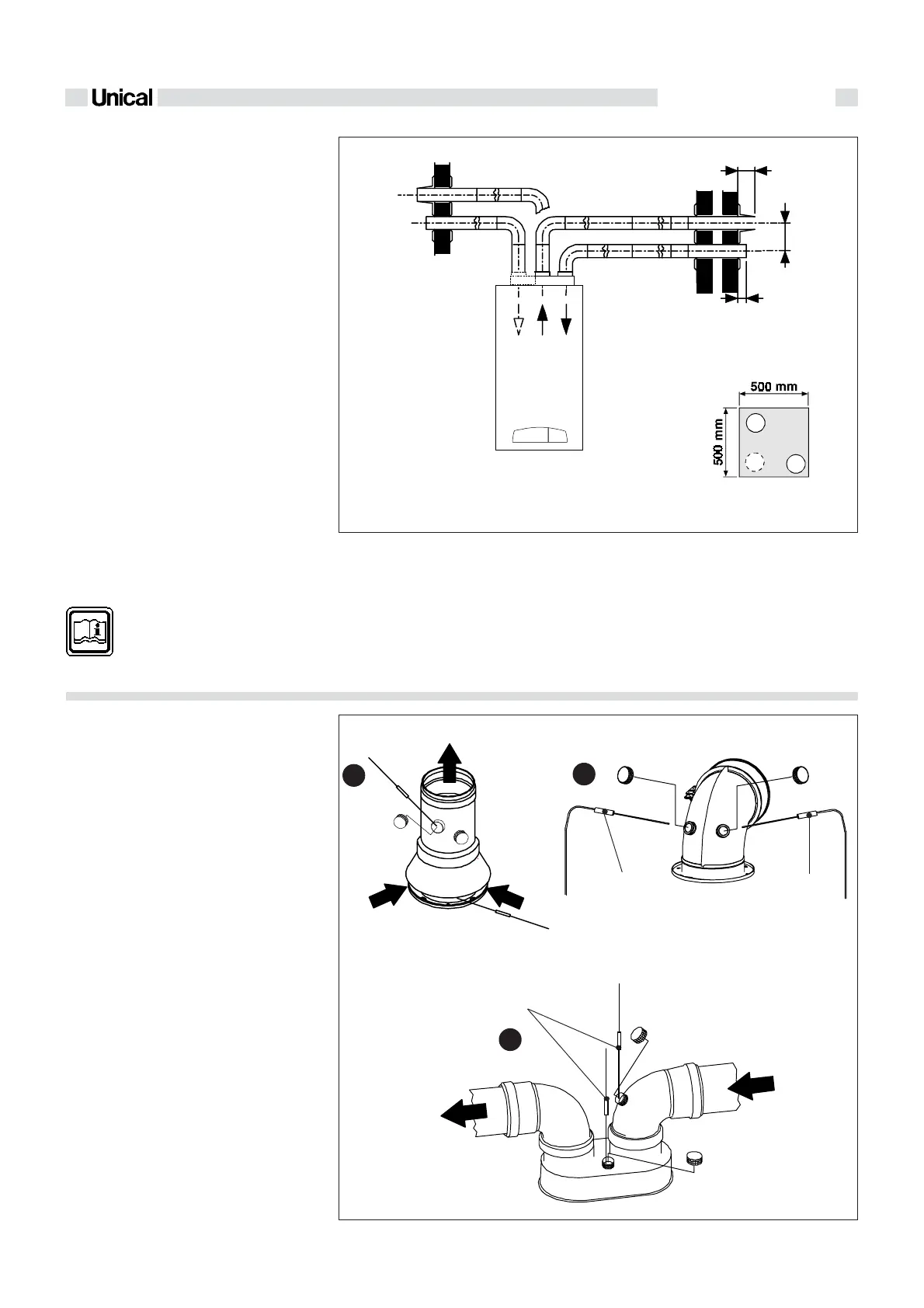

Example N.2 (fig. 19)

Primary air suction from perimeter wall and

flue gas discharge from the same outside pe-

rimeter wall.

Maximum allowable pressure loss:

50 Pa (IVEN 04 TFS 24)

60 Pa (IVEN 04 TFS 28)

Example N.2

Aria

Sonda

analizzatore

1

Fumi

B

2

Loading...

Loading...