27

Adjustment info

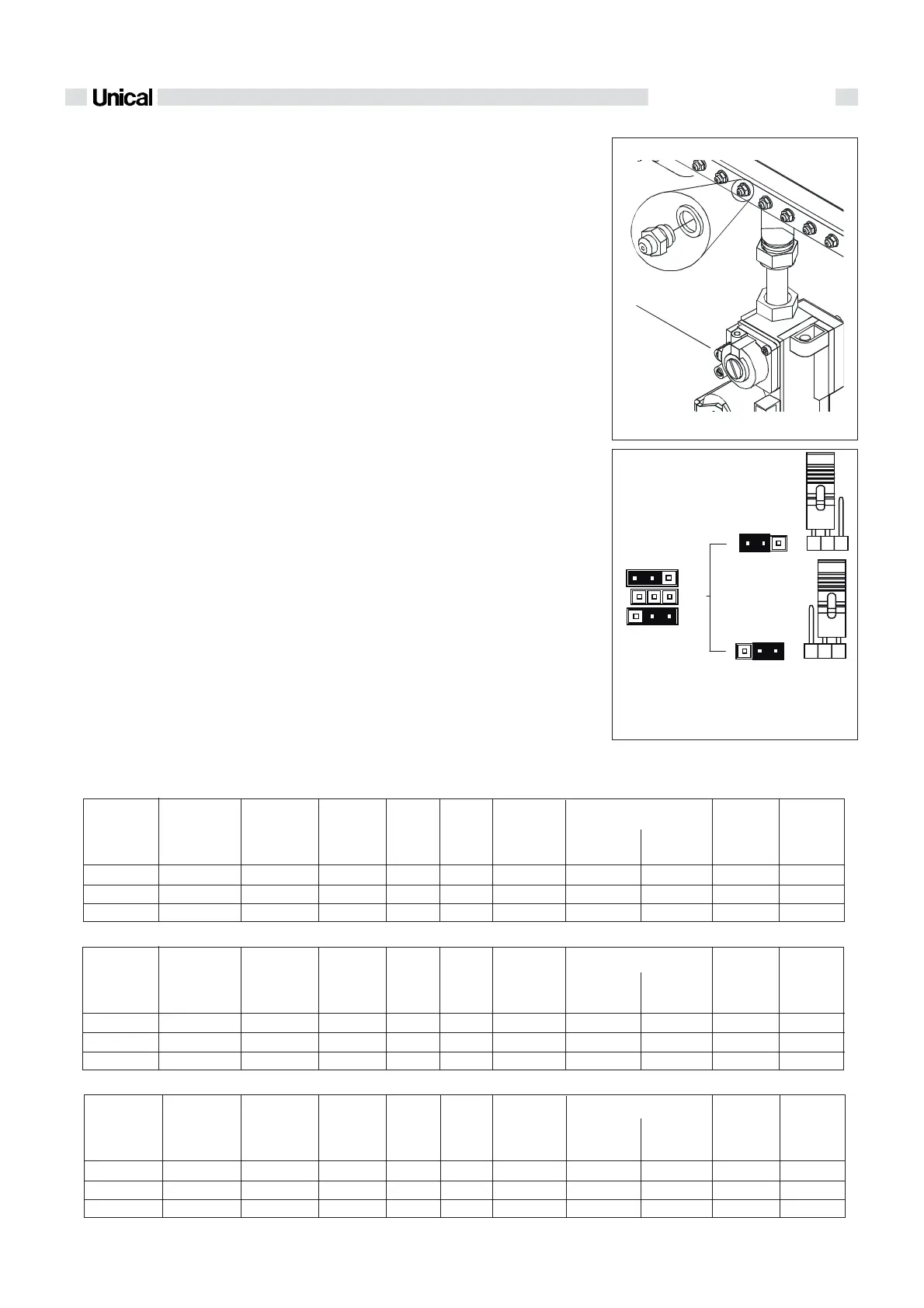

fig. 32

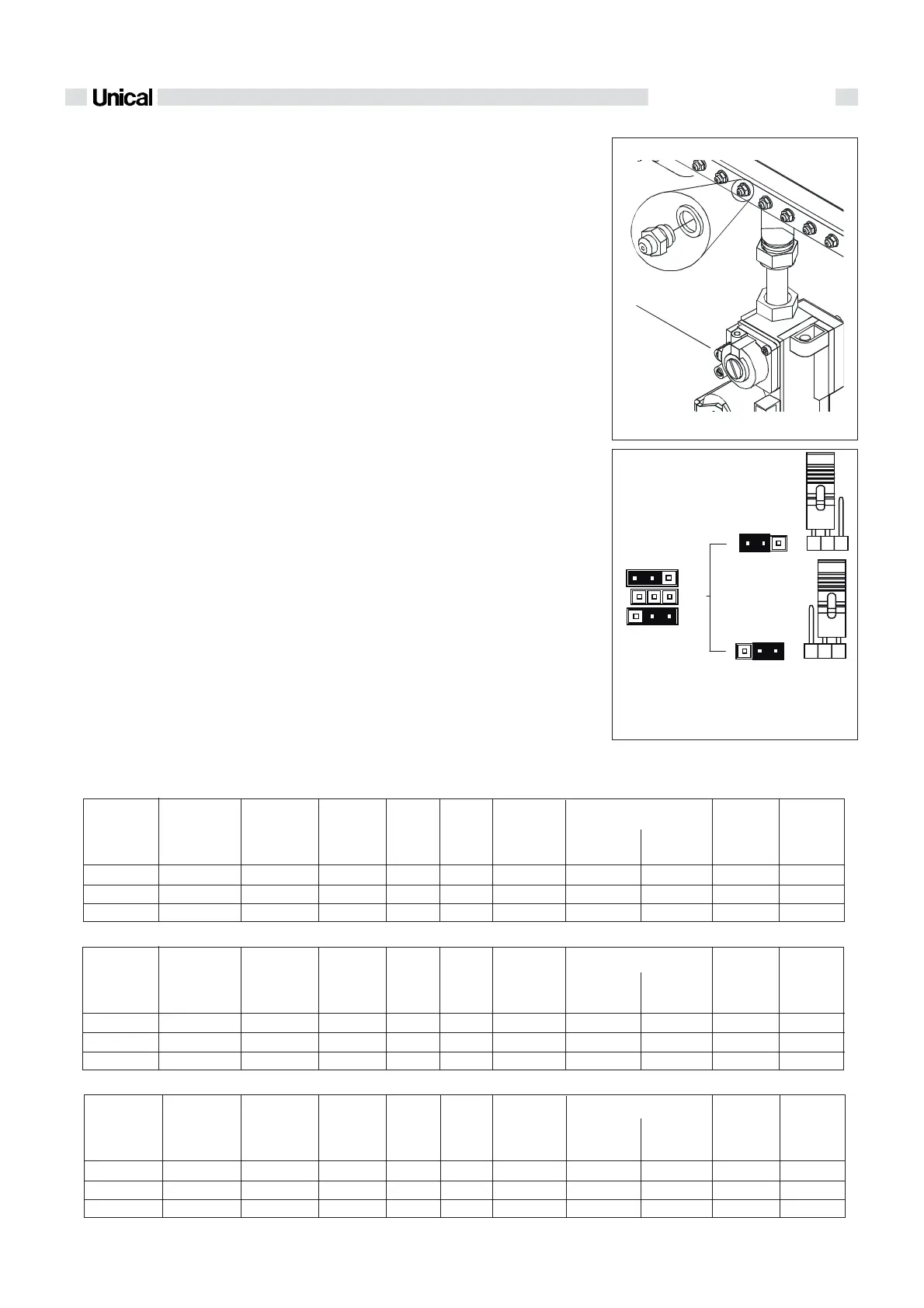

fig. 33

LPG

JP1

NA T

LPG

NA T

1

IVEN 04 CTN 24 F - IVEN 04 RTN 24

Gas

consump-

tion

max.

Natural gas

Propan

Butan

10,07 - 23,88

10,07 - 23,88

10,07 - 23,88

11,5 - 26,5

11,5 - 26,5

11,5 - 26,5

20

37

28-30

14

14

14

-

-

-

IVEN 04 CTFS 24 F - IVEN 04 RTFS 24

9,95 - 23,94

9,95 - 23,94

9,95 - 23,94

11,5 - 26,5

11,5 - 26,5

11,5 - 26,5

20

37

28-30

14

14

14

-

-

-

IVEN 04 CTFS 28 F - IVEN 04 RTFS 28

9,8 - 27,45

9,8 - 27,45

9,8 - 27,45

11,5 - 30,5

11,5 - 30,5

11,5 - 30,5

20

37

28-30

14

14

14

-

-

-

Natural gas

Propan

Butan

Natural gas

Propan

Butan

1,25

0,75

0,75

2,1

6,4

4,6

11,0

32,1

25,8

1,22 m³/h

0,89 kg/h

0,91 kg/h

2,80 m³/h

2,06 kg/h

2,09 kg/h

1,25

0,75

0,75

2,0

6,2

4,8

10,8

35,3

27,1

1,22 m³/h

0,89 kg/h

0,91 kg/h

2,80 m³/h

2,06 kg/h

2,09 kg/h

1,25

0,78

0,78

2,1

4,4

3,7

13,8

35,5

27,4

1,23 m³/h

0,89 kg/h

0,91 kg/h

3,24 m³/h

2,37 kg/h

2,40 kg/h

JP1: For nat. gas boilers, the jumper is

on NAT.

For LPG boilers, the jumper is on

LPG.

2.7 - MODIFICATION FOR

OTHER GASES

The boilers are manufactured for the type of

gas specifically required upon order.

Any subsequent conversion must be perfor-

med by qualified technicians who will use the

kits supplied by Unical and perform the con-

version and required adjustments for correct

preparation of the boiler for use.

To convert the boiler from one type of gas to

another proceed as follows:

for conversion from natural gas to LPG

- remove the main burner;

- disassemble injectors “1” (fig. 32) of the

main burner and replace them with those

with a diameter corresponding to the new

type of gas (see table “INJECTORS -

PRESSURES”);

- reassemble the main burner;

- position the jumper on the modulation PCB

in the panel board as shown in fig. 33

- remove plug ‘’A’’ (fig.28) on the gas valve

and fully tighten max pressure adjustment

screws ‘’B’’ (fig.29)

- check the pressure value upstream the gas

valve (see table “INJECTORS - PRESSU-

RES”) and adjust the pressure of the bur-

ner as indicated in section “ADJUSTING

THE BURNER”

- check that the burner is functioning pro-

perly;

- check that there are no gas leaks.

- tighten the plug ”A” (fig.28) of the max

pressure adjustment screw

- when the conversion is completed, fill in

label supplied with the kit with the informa-

tion required and stick it onto the boiler

alongside the data plate.

for conversion from LPG to natural gas

- remove the main burner;

- disassemble injectors “1” (fig. 32) of the

main burner and replace them with those

with a diameter corresponding to the new

type of gas (see table “INJECTORS -

PRESSURES”);

- reassemble the main burner;

- position the jumper on the modulation PCB

in the panel board as shown in figure 33;

- remove plug ‘’A’’ (fig.28) on the gas valve

- check the pressure value upstream the gas

valve (see table “INJECTORS - PRESSU-

RES”) and adjust the burber pressure as

indicated in section “ADJUSTING THE

BURNER”;

- check that the burner is functioning pro-

perly;

- check that there are no gas leaks.

- tighten the plug “A” (fig.28) of the max

pressure adjustment screw;

- when the conversion is completed, fill in

label supplied with the kit with the informa-

tion required and stick it onto the boiler

alongside the data plate.

Nominal

Output

(kW)

Nominal

input

(kW)

Supply

pressure

(mbar)

Ø

Diaphragme

(mm)

min.

(mbar)

max

(mbar)

Ø

Nozzles

(mm)

Gas

consump-

tion

min.

The pressures at the burner indicated in the following table must be checked after the boiler has been operating for 3 minutes.

TABLE NOZZLES - PRESSION - DIAPHRAGME - CONSUMPTION

Tipe of

gas

No. of

Nozzles

Burner pressure

Gas

consump-

tion

max.

Nominal

Output

(kW)

Nominal

input

(kW)

Supply

pressure

(mbar)

Ø

Diaphragme

(mm)

min.

(mbar)

max

(mbar)

Ø

Nozzles

(mm)

Gas

consump-

tion

min.

Tipe of

gas

No. of

Nozzles

Burner pressure

Gas

consump-

tion

max.

Nominal

Output

(kW)

Nominal

input

(kW)

Supply

pressure

(mbar)

Ø

Diaphragme

(mm)

min.

(mbar)

max

(mbar)

Ø

Nozzles

(mm)

Gas

consump-

tion

min.

Tipe of

gas

No. of

Nozzles

Burner pressure

Loading...

Loading...