0020244064_02 Operating and installation instructions 9

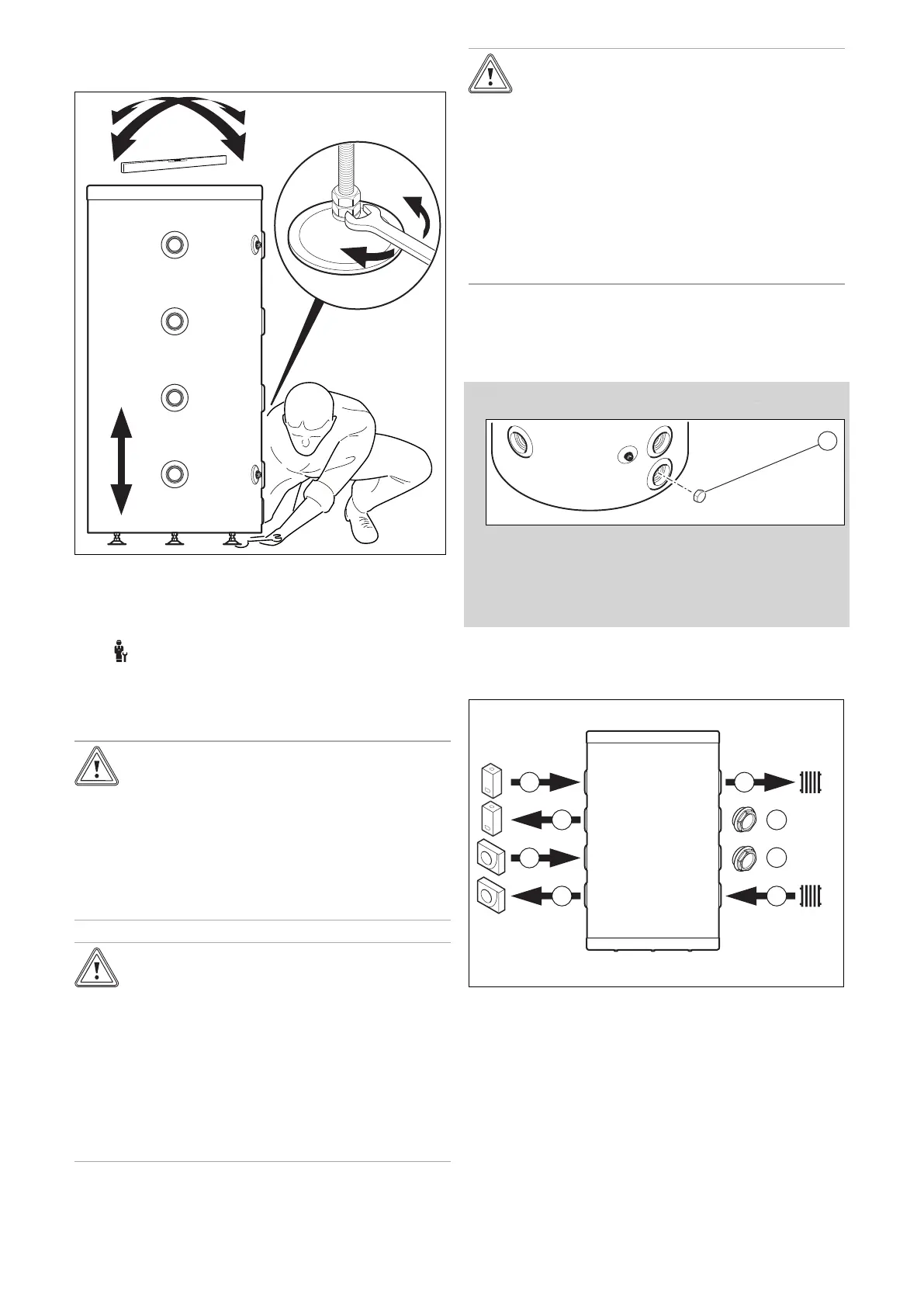

3. Install the three enclosed feet at the bottom of the cyl-

inder.

4. Use the adjustable feet and a spirit level to align the

product.

5 Installation

5.1 Hydraulics installation

5.1.1 Water-side connection

Caution.

Risk of material damage caused by

residues in the pipelines.

Welding remnants, sealing residues, dirt or

other residues in the pipelines may damage

the product.

▶ Flush the heating installation thoroughly

before installing the product.

Caution.

Risk of damage caused by heat transfer

when soldering.

The heat that is transferred during solder-

ing may lead to damage to the expanded

polypropylene around the product and to the

seals on the connectors.

▶ Protect the product's insulating casing.

▶ Do not solder the connectors if these have

been screwed onto the product.

Caution.

Risk of material damage caused by corro-

sion

Due to non-diffusion-tight plastic pipes in the

heating installation, air gets into the heating

water. Air in the heating water causes corro-

sion in the heat generator circuit and in the

product.

▶ If you use non-diffusion-tight plastic pipes

in the heating installation, ensure that no

air gets into the heat generator circuit.

1. Attach a draining cock at the lowest point in the install-

ation.

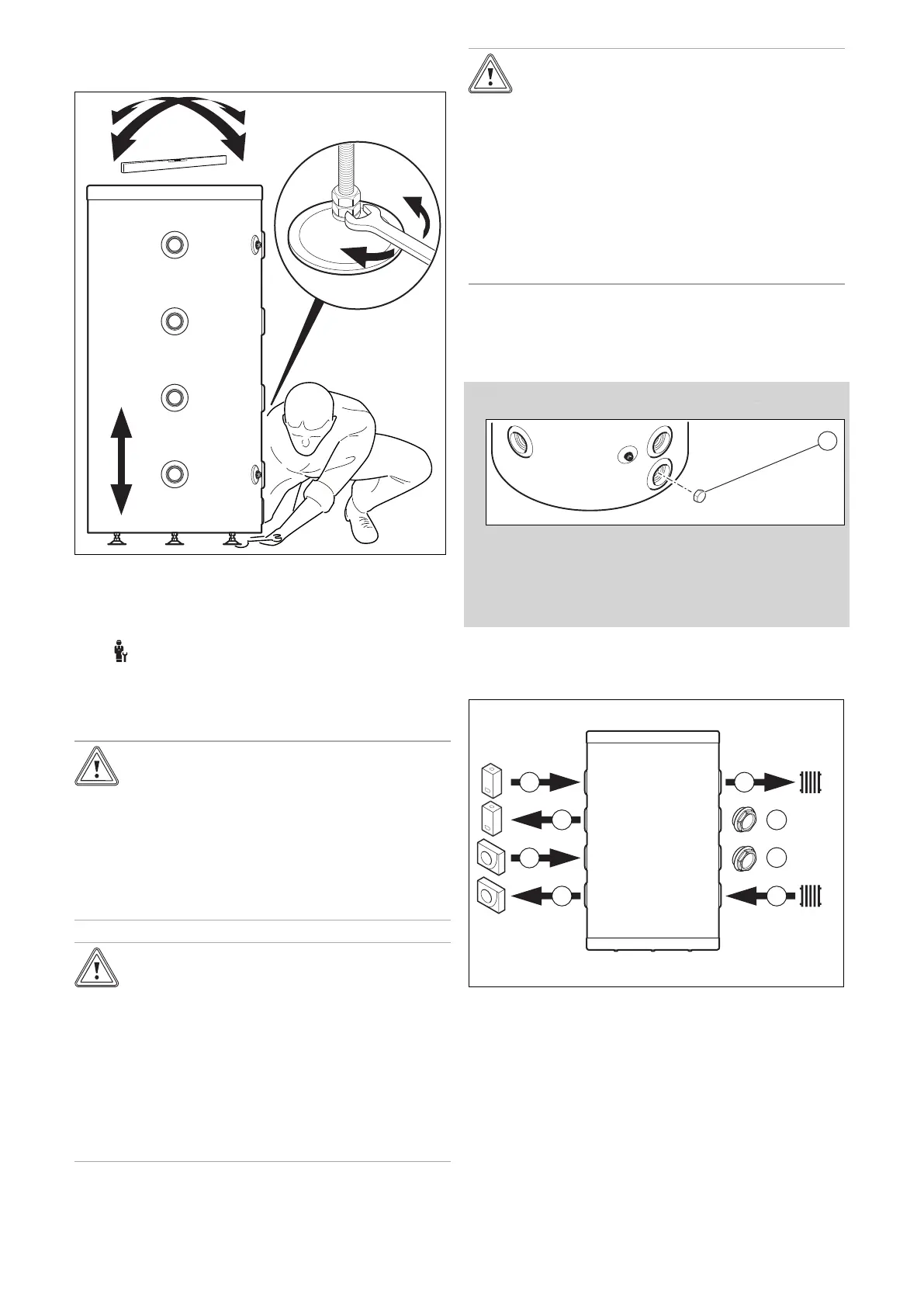

2. Depending on your installation, connect the circuits in

accordance with the basic diagrams shown below.

Validity: VPS R 200/1 B

▶ Connect a draining cock to the drain connection on the

cylinder.

▶ If you do not connect a draining cock, attach the drain

plug (1) in order to guarantee the leak-tightness of the

cylinder.

5.1.2 Basic hydraulic connection diagram

5.1.2.1 Case no. 1

1 Heat pump

2 Boiler

3 Heating circuit

4 Plug

Loading...

Loading...