18

Installation

I

nstallation

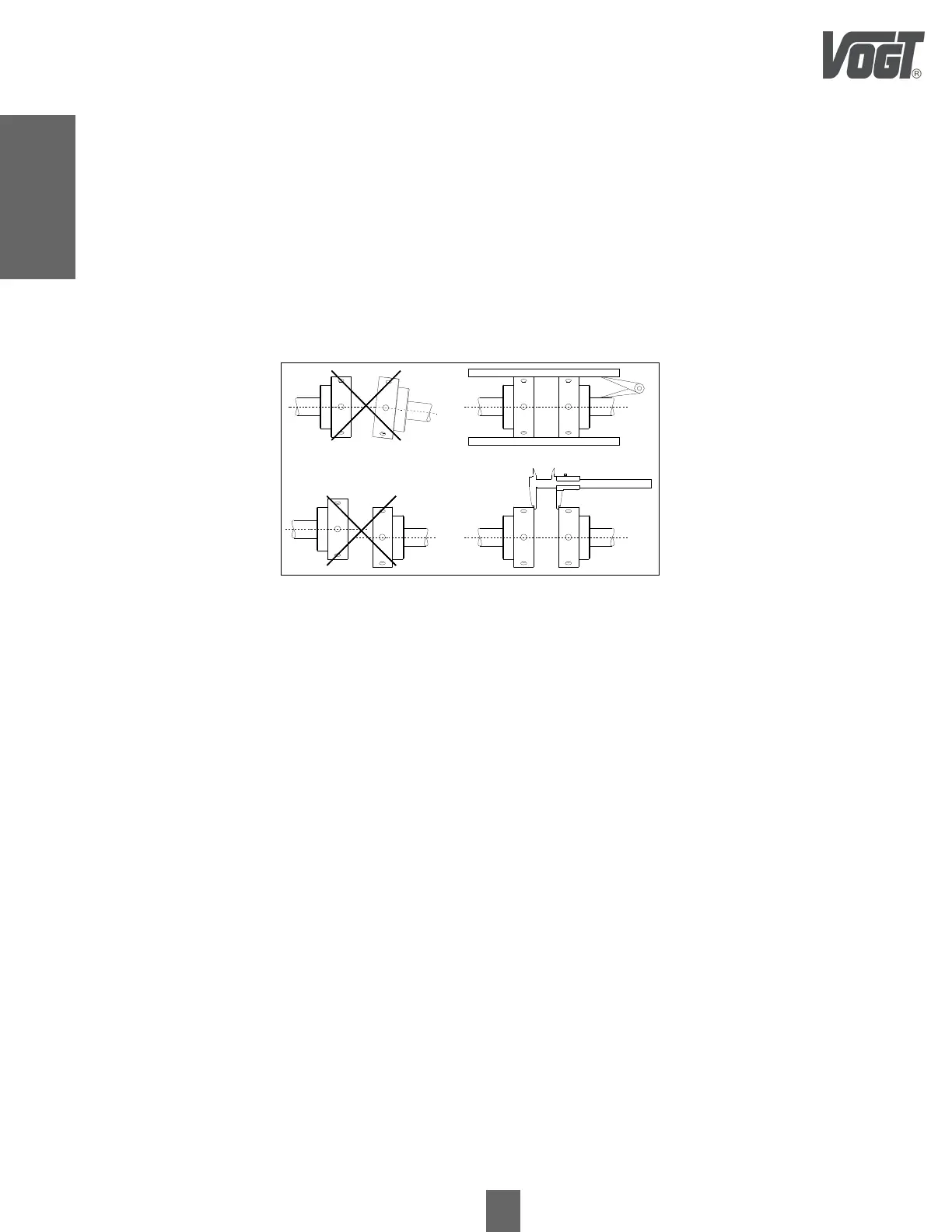

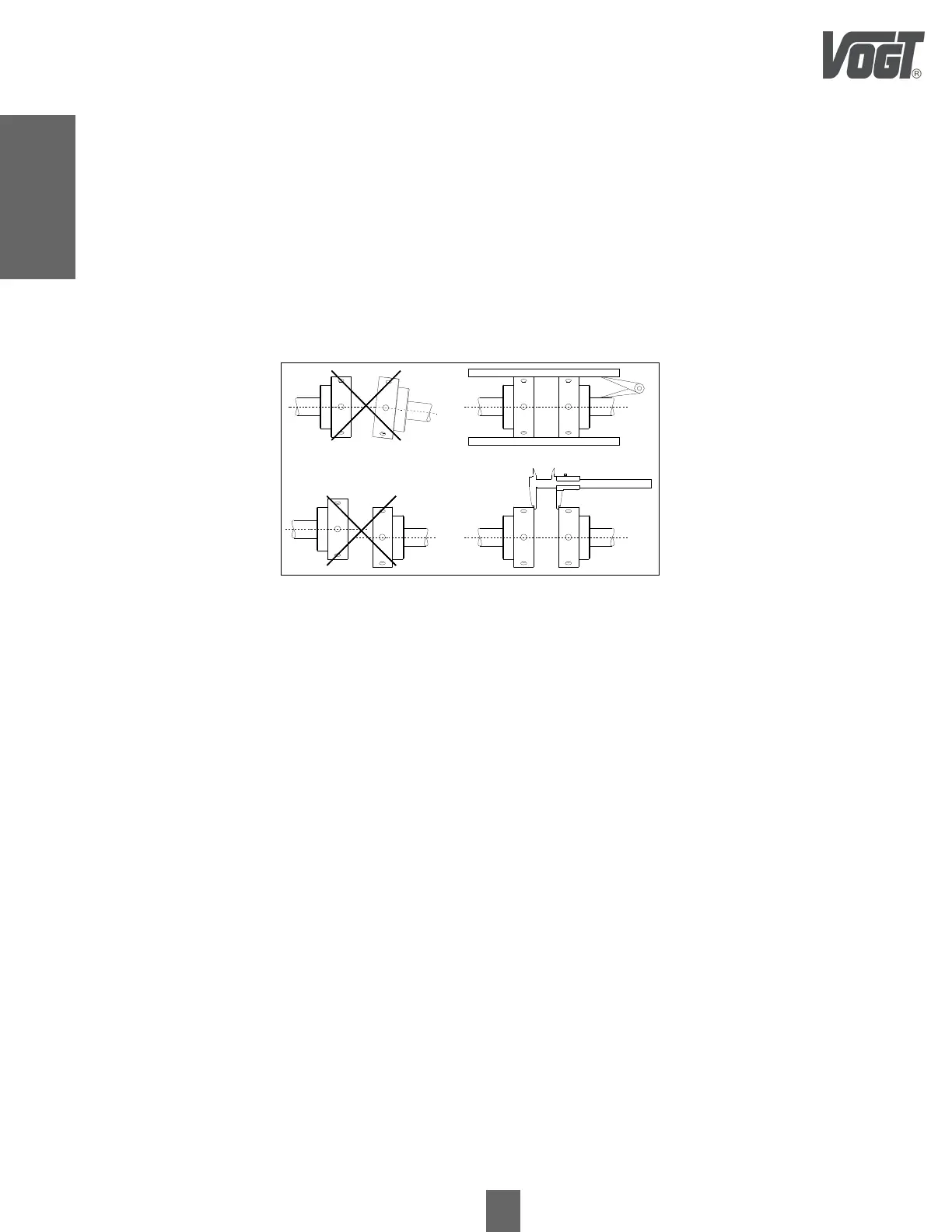

5.8 Alignment

Pumping equipment is assembled in the factory by qualified personnel; however, during transportation or handling, the

equipment can suffer stresses that can cause misalignment between the pump and the motor, which can lead to bearing and

coupling failures. Therefore it is important to check and correct the alignment when necessary, see figure 14. If the equipment

handles high temperature fluids, the final alignment should be done with the equipment at operating temperature.

The equipment should always be aligned after everything is assembled and ready for start-up. The correct alignment of the

standard coupling consists of correcting the possible errors of parallelism and concentricity, using calibrated laims in the motor.

Figure 14

Loading...

Loading...